Nuclear process pipeline leakage rate detection device function verification test loop system

A technology for process pipelines and detection devices, which is applied in nuclear engineering, nuclear power generation, nuclear reactor monitoring, etc., can solve problems such as verification difficulties and leakage, and achieve the effect of ensuring reliability and effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

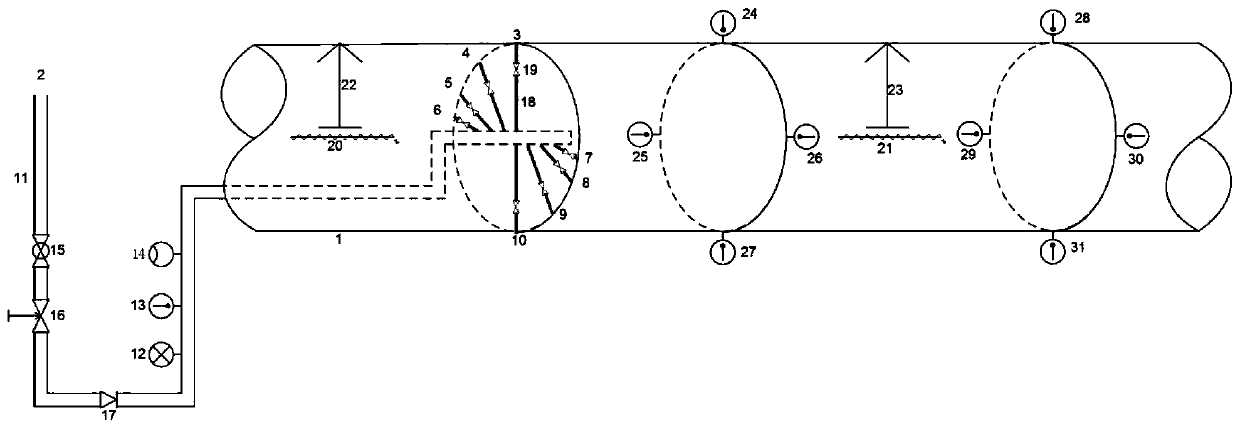

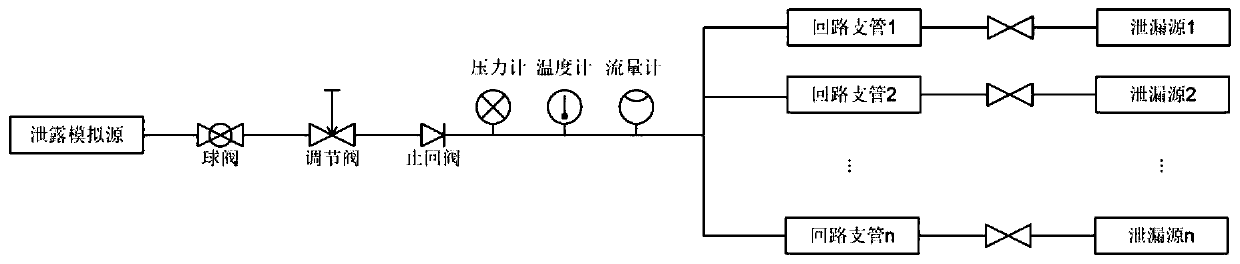

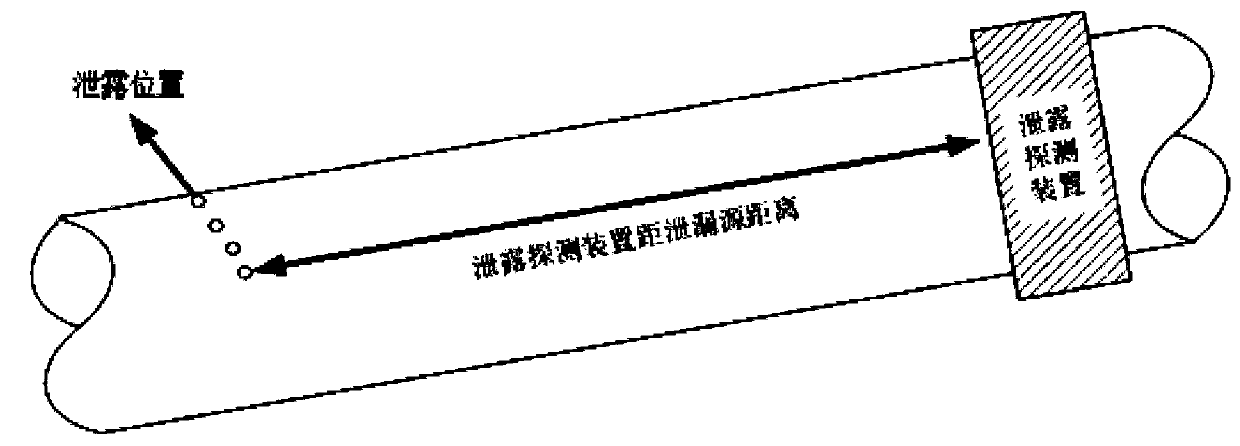

[0021] Such as Figure 1 to Figure 3 As shown, the nuclear process pipeline leakage rate detection device function verification test loop system of the present invention includes a loop unit providing a fluid medium inside the high-energy tube and a simulated pipeline unit simulating the state of the leaking pipeline. The simulated pipeline unit includes a simulated real pipeline outer diameter size A cylindrical tube body 1 of the same material type, the cross section in the middle of the tube body 1 is distributed with openings 3, 4, 5, 6, 7, 8, and Hole 9 and Hole 10, Hole 3, Hole 4, Hole 5, Hole 6, Hole 7, Hole 8, Hole 9 and Hole 10 are used to simulate the leaking parts at different angles upward in the loop; The unit includes a temperature-adjustable and pressure-adjustable fluid medium source 2, a circuit main pipe 11 and several circuit branch pipes 18. One end of the circuit main pipe 11 is connected to the fluid medium source 2, and the other end of the circuit main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com