Traditional Chinese medicine privacy nursing plaster and preparation method thereof

A nursing sticker, private technology, applied in pharmaceutical formulations, pharmaceutical science, drug combination and other directions, can solve the problems of poor antibacterial and bactericidal effect, poor air permeability and waterproofness, etc., to improve the curative effect, strong adhesion, excellent air permeability and water absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

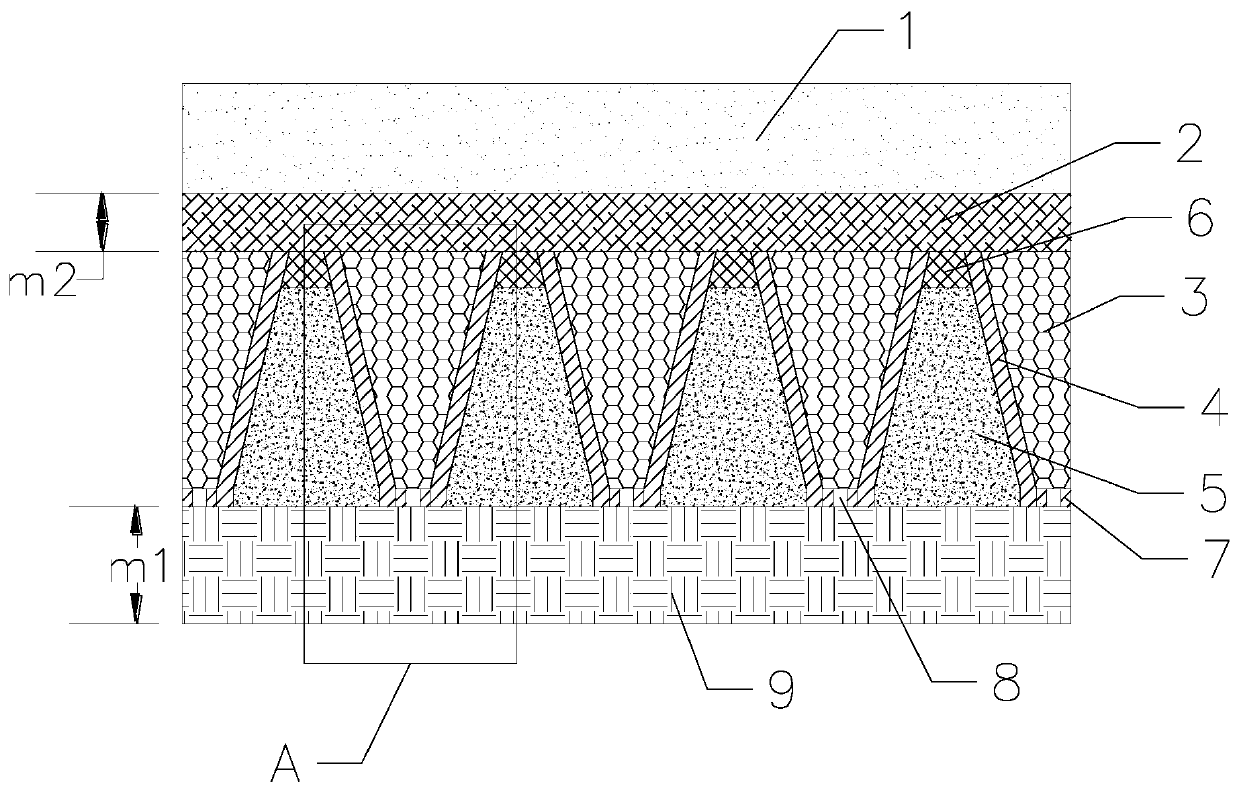

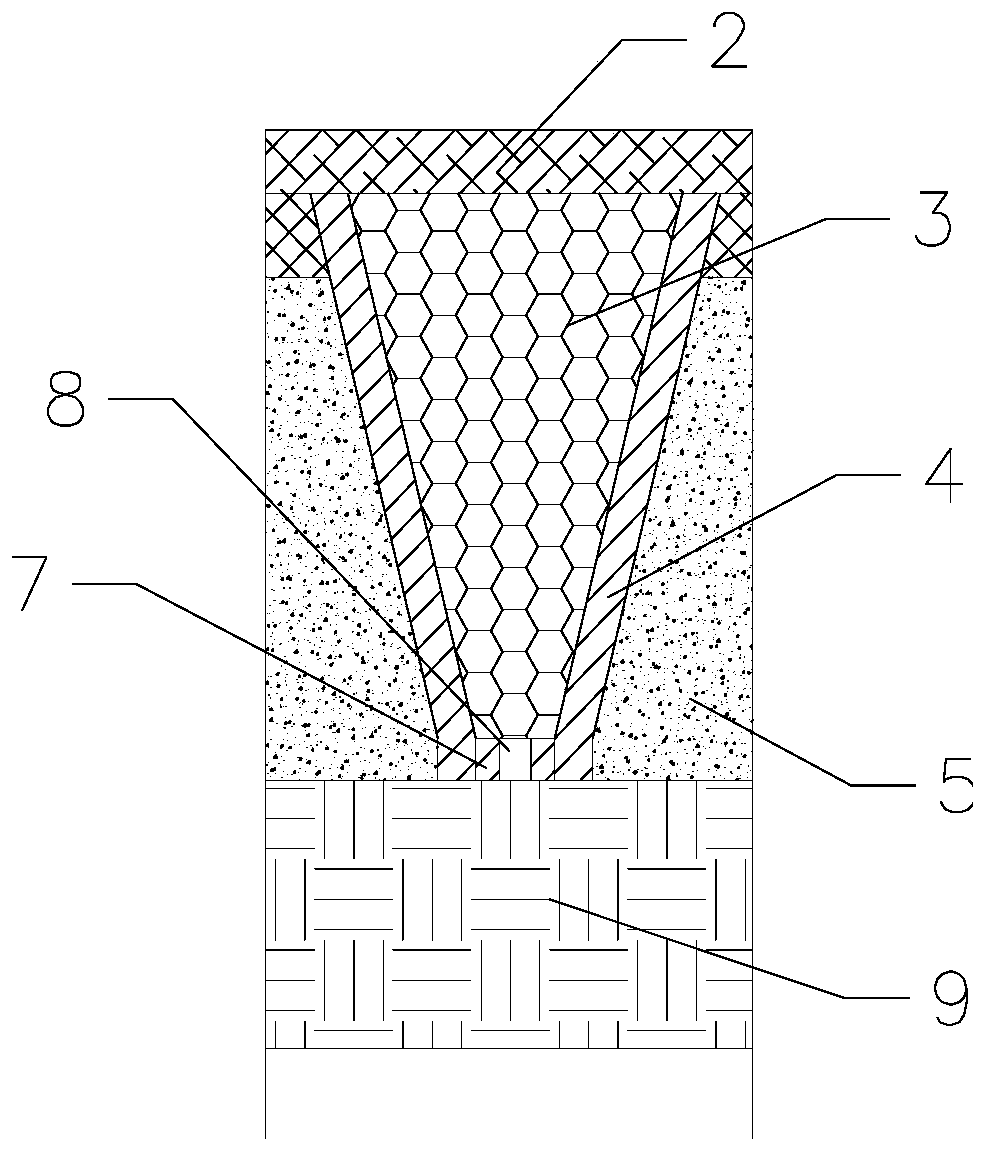

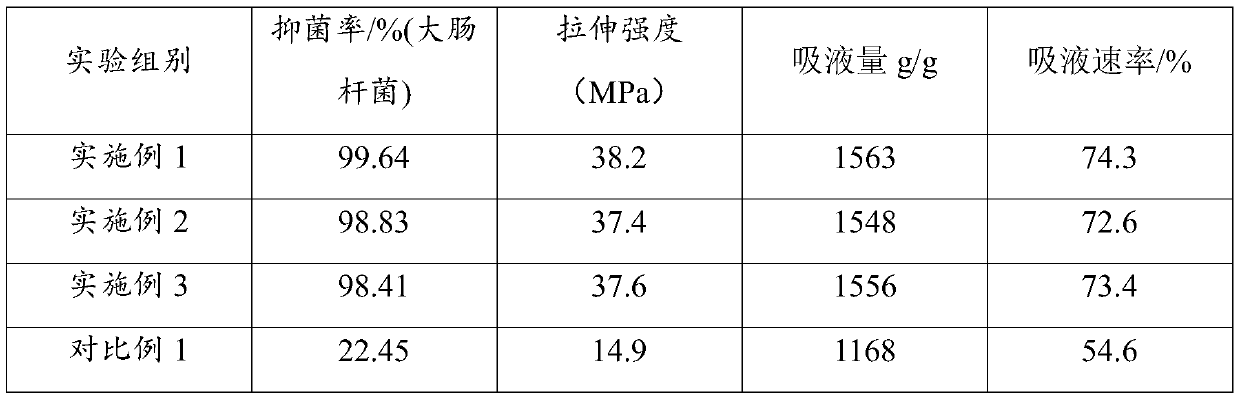

[0033] refer to Figure 1-2 , the traditional Chinese medicine private nursing patch proposed by the embodiment of the present invention comprises a plaster glue layer 1, a ointment filling layer 5 and a second gauze layer 9, and a first gauze layer 2, polylactic acid Antibacterial support layer 3 and adhesive layer 7, the first gauze layer 2 is bonded between the ointment adhesive layer and the polylactic acid antibacterial support layer 3, and the polylactic acid antibacterial support layer 3 is bonded between the first gauze layer 2 and the adhesive layer 7 Between, the adhesive layer 7 is bonded between the second gauze layer 9 and the polylactic acid antibacterial support layer 3, the polylactic acid antibacterial support layer 3 is provided with a plurality of skeletons 4 of trapezoidal structure, and the ointment filling layer 5 is filled in the skeleton 4 Inside, between the ointment filling layer 5 and the first gauze layer 2, a ventilating net 6 is bonded, the polyla...

Embodiment 2

[0048] refer to Figure 1-2 , the traditional Chinese medicine private nursing patch proposed by the embodiment of the present invention comprises a plaster glue layer 1, a ointment filling layer 5 and a second gauze layer 9, and a first gauze layer 2, polylactic acid Antibacterial support layer 3 and adhesive layer 7, the first gauze layer 2 is bonded between the ointment adhesive layer and the polylactic acid antibacterial support layer 3, and the polylactic acid antibacterial support layer 3 is bonded between the first gauze layer 2 and the adhesive layer 7 Between, the adhesive layer 7 is bonded between the second gauze layer 9 and the polylactic acid antibacterial support layer 3, the polylactic acid antibacterial support layer 3 is provided with a plurality of skeletons 4 of trapezoidal structure, and the ointment filling layer 5 is filled in the skeleton 4 Inside, between the ointment filling layer 5 and the first gauze layer 2, a ventilating net 6 is bonded, the polyla...

Embodiment 3

[0063] refer to Figure 1-2 , the traditional Chinese medicine private nursing patch proposed by the embodiment of the present invention comprises a plaster glue layer 1, a ointment filling layer 5 and a second gauze layer 9, and a first gauze layer 2, polylactic acid Antibacterial support layer 3 and adhesive layer 7, the first gauze layer 2 is bonded between the ointment adhesive layer and the polylactic acid antibacterial support layer 3, and the polylactic acid antibacterial support layer 3 is bonded between the first gauze layer 2 and the adhesive layer 7 Between, the adhesive layer 7 is bonded between the second gauze layer 9 and the polylactic acid antibacterial support layer 3, the polylactic acid antibacterial support layer 3 is provided with a plurality of skeletons 4 of trapezoidal structure, and the ointment filling layer 5 is filled in the skeleton 4 Inside, between the ointment filling layer 5 and the first gauze layer 2, a ventilating net 6 is bonded, the polyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com