Screening device for construction aggregate

A screening equipment, sand and gravel technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inability to adjust the screening efficiency, poor screening effect, inability to automatically feed materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

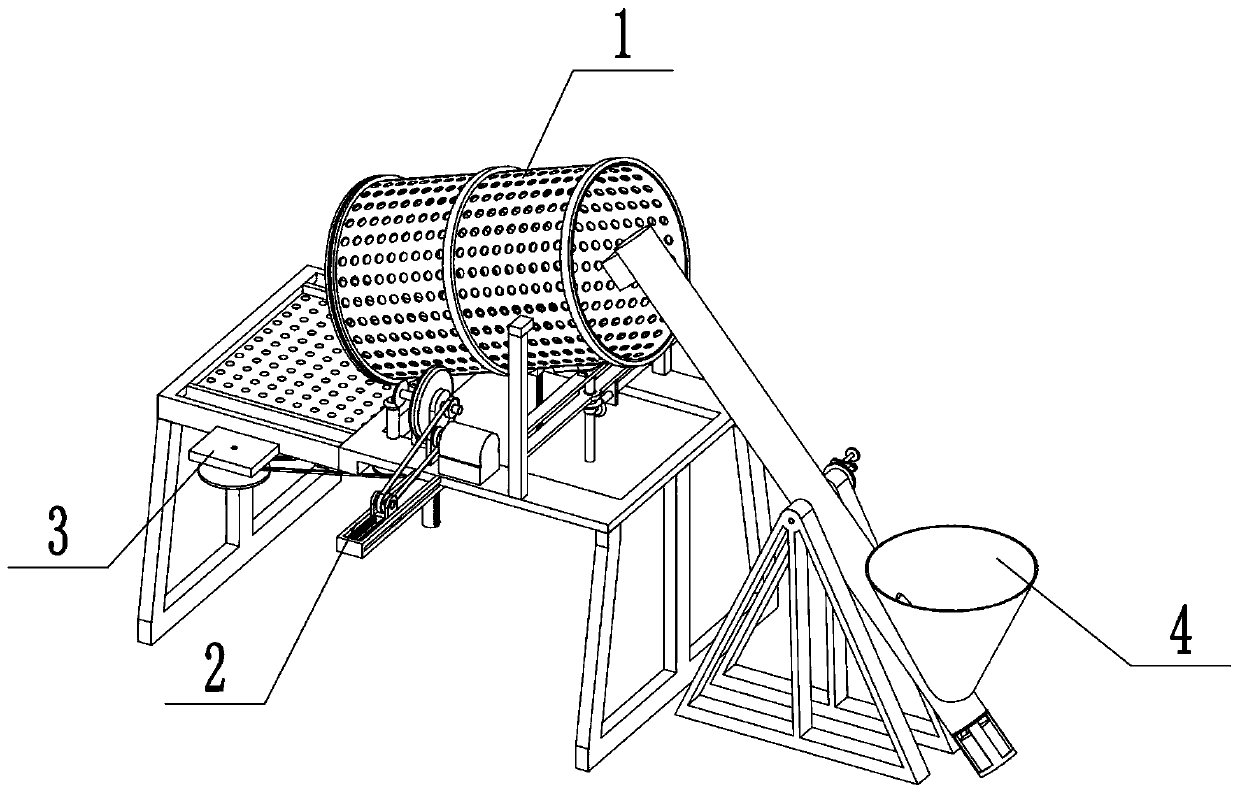

[0031] Combine below Figure 1-16 In this embodiment, a construction sand and stone screening equipment includes an inclined screen assembly 1, an inclined screen rotating assembly 2, a reciprocating screen assembly 3 and a feeding assembly 4, the inclined screen assembly 1 and the inclined screen The rotating assembly 2 is connected, the inclined screen rotating assembly 2 is connected with the reciprocating screen assembly 3, and the reciprocating screen assembly 3 is connected with the inclined screen assembly 1.

specific Embodiment approach 2

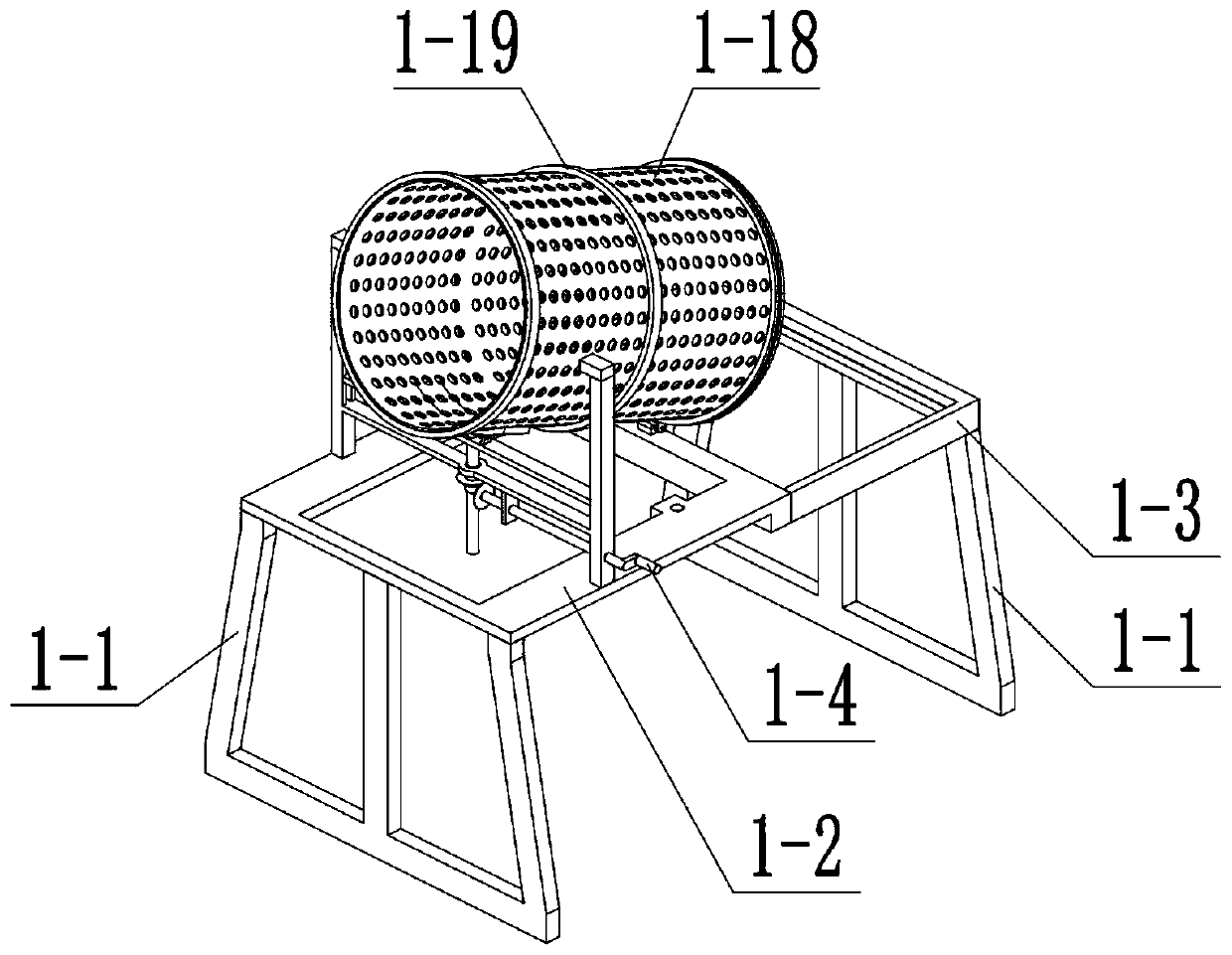

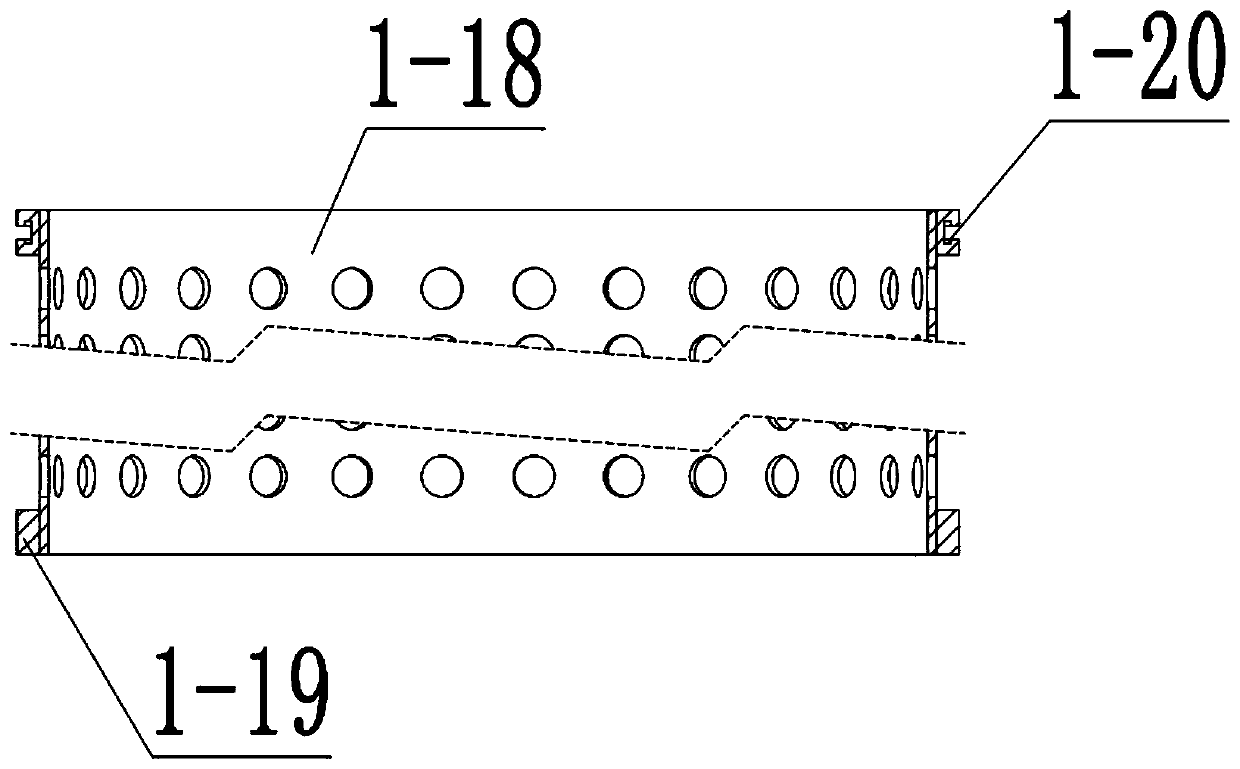

[0033] Combine below Figure 1-16This embodiment, this embodiment will further explain Embodiment 1. The inclined screen assembly 1 includes legs 1-1, frame I1-2, frame II1-3, handle 1-4, handle shaft 1-5, column 1-6, chute Ⅰ1-7, limit block 1-8, support rod 1-9, rocker shaft support 1-10, bevel gear Ⅰ1-11, bevel gear Ⅱ1-12, thread sleeve Cylinder 1-13, threaded rod 1-14, slide plate 1-15, slide plate lug 1-16, support plate 1-17, screen 1-18, screen support 1-19, chute II 1-20, slider 1-21. Slider lug I1-22 and slider lug II1-23, two outriggers 1-1 are respectively connected with support frame I1-2 and support frame II1-3, and support frame I1-2 is connected with support The frame II1-3 is connected, the two columns 1-6 are connected with the support frame I1-2, the rocker 1-4 is connected with the rocker shaft 1-5, and the rocker shaft 1-5 is rotated with the column 1-6 Connection, the chute Ⅰ1-7 is located on the column 1-6, the two limit blocks 1-8 are respectively conne...

specific Embodiment approach 3

[0035] Combine below Figure 1-16 This embodiment, this embodiment will further explain Embodiment 1. The inclined screen rotating assembly 2 includes a motor I 2-1, a motor I shaft 2-2, a motor I shaft bracket 2-3, a sprocket I 2-4, Chain Ⅰ2-5, sprocket Ⅱ2-6, sprocket Ⅲ2-7, tensioning shaft 2-8, tensioning slider 2-9, tensioning slider rail 2-10, tension spring 2-11, sprocket Ⅱ shaft 2-12, sprocket Ⅱ shaft bracket 2-13, friction wheel 2-14, bevel gear Ⅲ 2-15, bevel gear Ⅳ 2-16, bevel gear Ⅳ shaft 2-17, limit slider 2-18, slide Barrel 2-19, spring I 2-20, connecting shaft 2-21, sliding strut 2-22, strut sliding cylinder 2-23 and compression spring 2-24, sliding strut, motor I 2-1 and supporting frame I 1- 2-phase connection, motor I 2-1 is connected to motor I shaft 2-2, motor I shaft 2-2 is rotationally connected to motor I shaft bracket 2-3, motor I shaft bracket 2-3 is connected to support frame I1-2 , Motor I shaft 2-2 is connected with sprocket I2-4, sprocket I2-4, chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com