Full-automatic battery film stripping equipment

A film peeling and fully automatic technology, applied in battery recycling, waste collector recycling, packaging, etc., can solve problems such as accidental injury of cylindrical products and lower pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

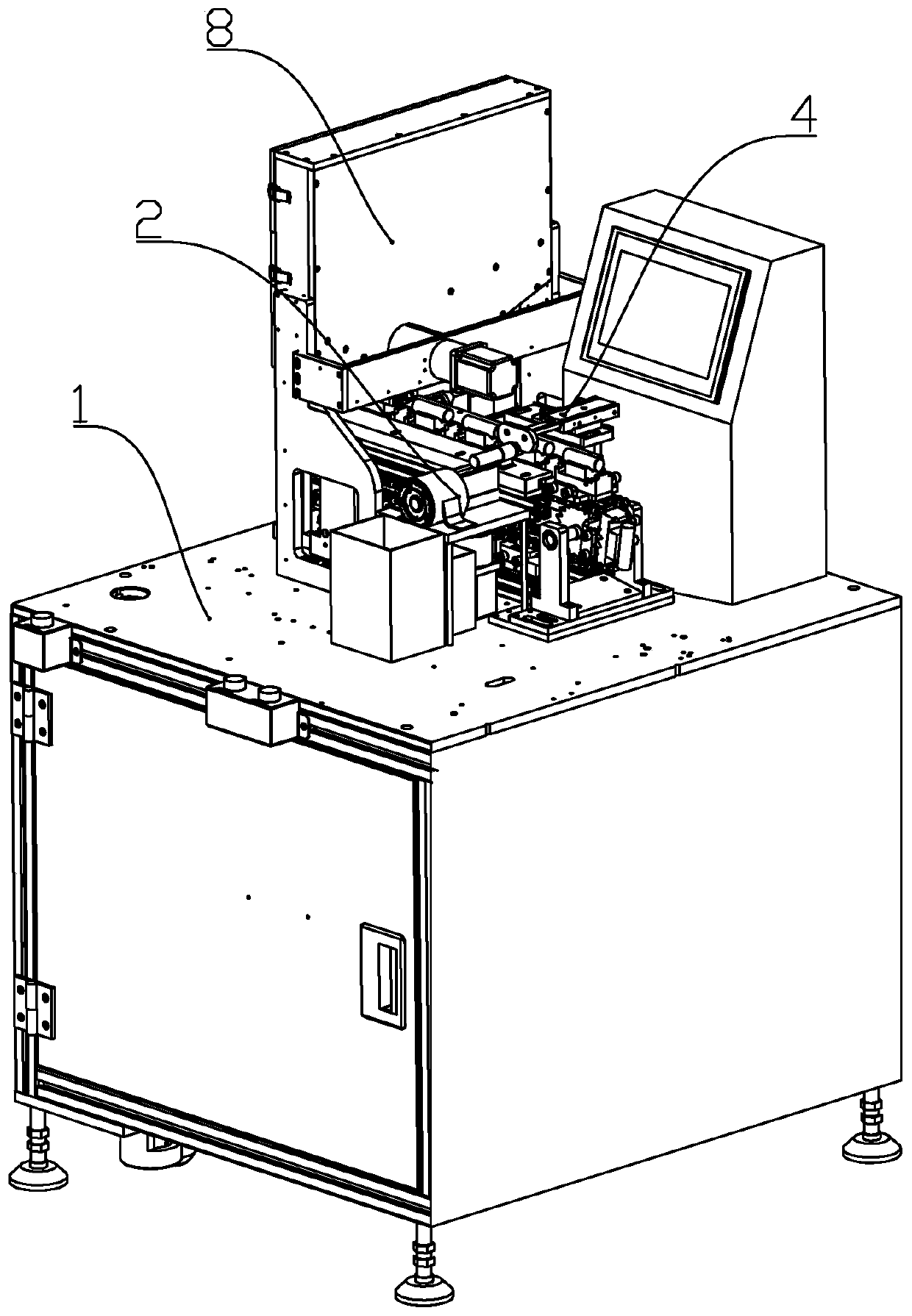

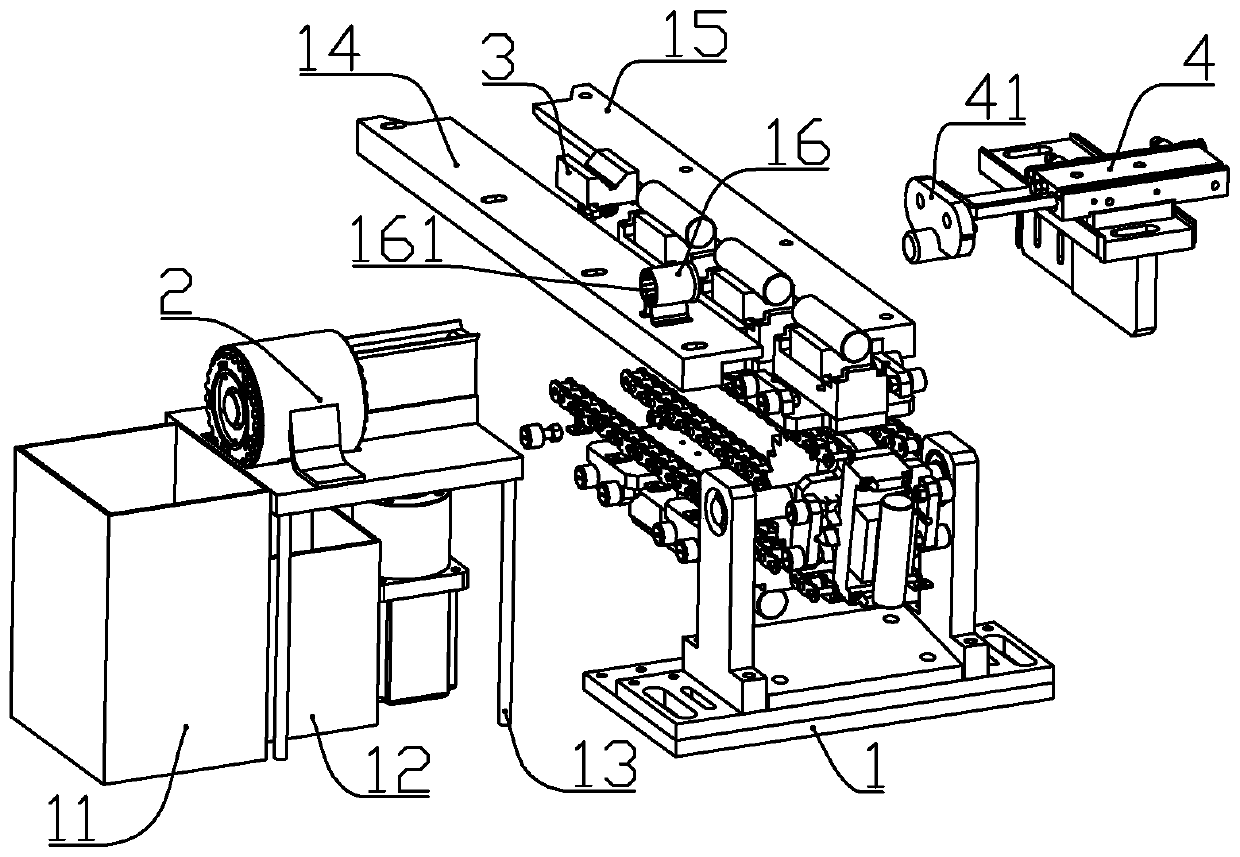

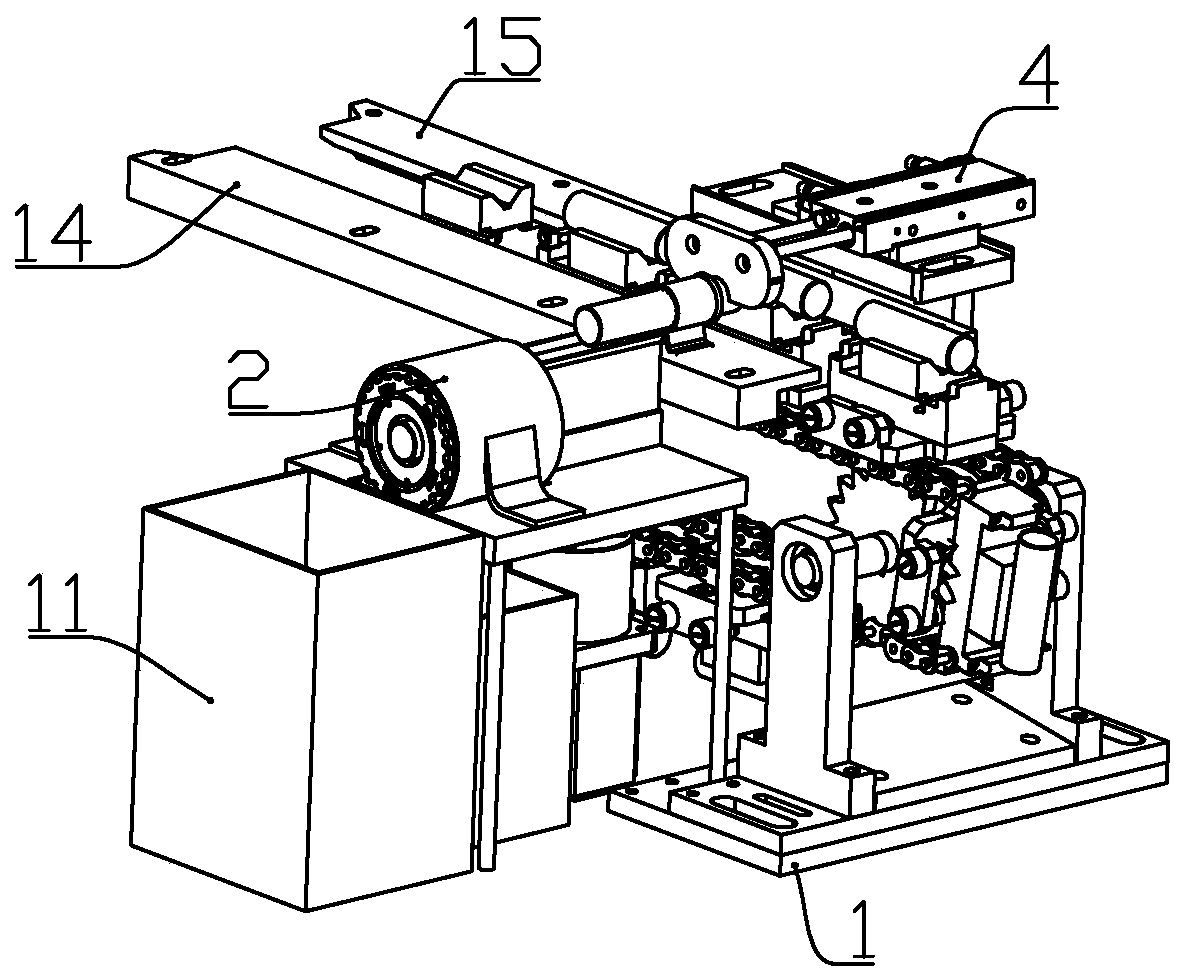

[0048] according to Figure 1 to Figure 20 As shown, a fully automatic battery film peeling device described in this embodiment includes a frame 1, a film stripping assembly 2 for cutting the battery film, and a conveyor belt 5 fixedly connected to the frame 1 for transferring batteries , Feeding component 3.

[0049] The peeling assembly 2 includes a cutting cylinder 25, a bracket 13 fixedly connected to the frame, and a battery recovery box 11 for recycling batteries; two ends of the cutting cylinder 25 are respectively rotatably connected with a cutter mounting plate 253; The two cutter mounting disks 253 are parallel to each other; the center of the cutter mounting disk 253 is formed with a battery fixing hole 2335 passing through the cutter mounting disk 253; The distributing tool mounting slots 2531 are formed with a collar 2534 concentric with the tool mounting disc 253 on the separated side; 253 is an arc-shaped rotating groove 2532; the ground center of the tool mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com