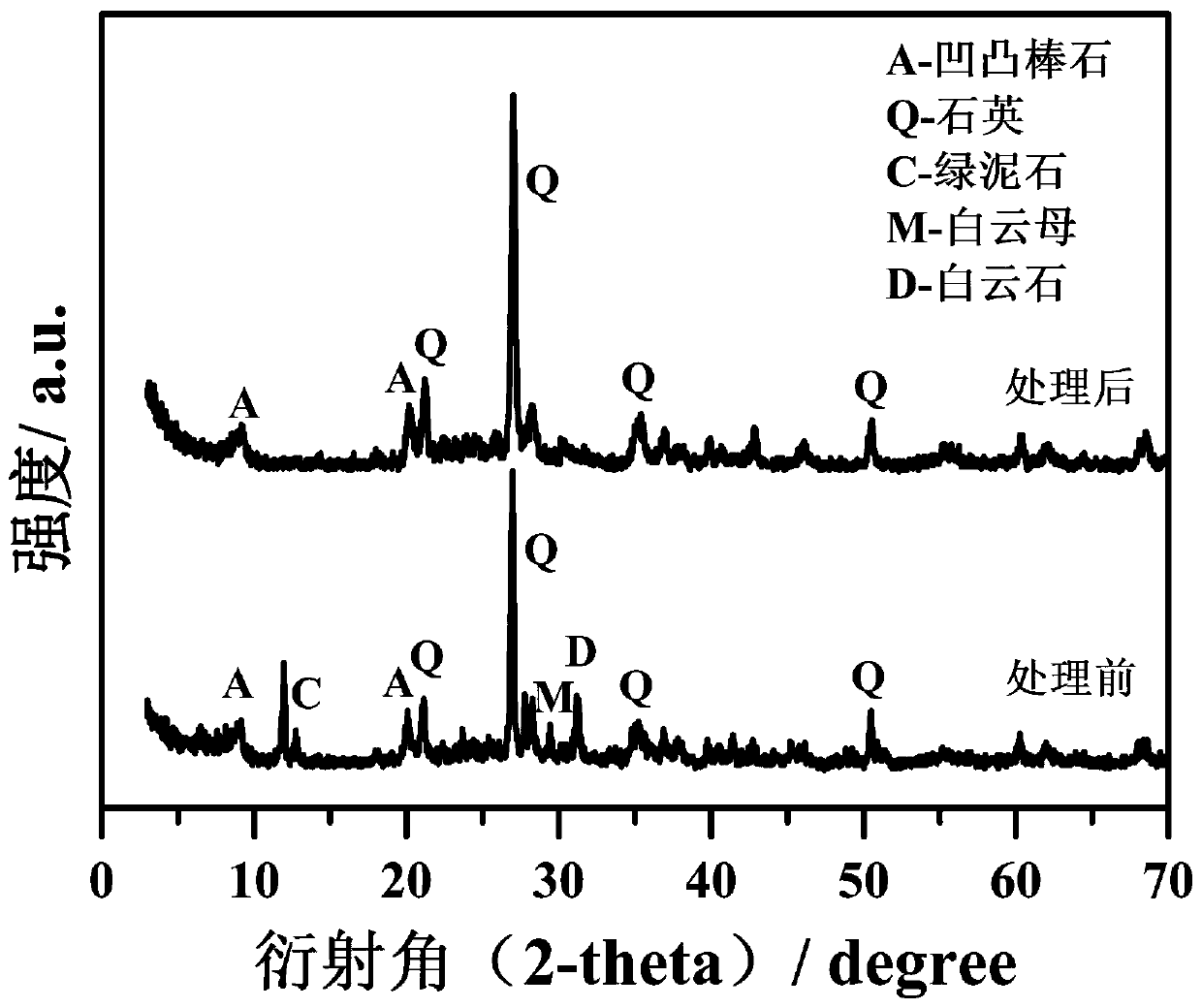

Attapulgite clay reduction-magnetic separation coupling continuous iron removal, whitening and purification method

A technology of attapulgite clay and purification method, which is applied in chemical instruments and methods, reduced water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of organic solvents increasing production and environmental protection costs, unfavorable continuous treatment, etc. , to achieve a high degree of process automation and continuity, to facilitate industrial production, and to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Taking Gansu brick red attapulgite clay as an example, pulverize the mineral powder with a grinder, add water to adjust the solid-to-liquid ratio of the slurry to 1:4, and use 8% phosphoric acid to adjust the pH value of the slurry to 0~ 1. Soak with mechanical stirring for 2 hours.

[0018] (2) Add the above-mentioned acidic attapulgite slurry into the enamel reaction kettle with a glass loop magnetic separator, slowly add aluminum powder into the above-mentioned slurry under mechanical stirring, the quality of the added aluminum powder is 10% of the mass of the attapulgite clay, continue Stir to form an attapulgite reduction slurry; keep the pH value of the slurry in the range of 0 to 1 during the reaction process by dropping phosphoric acid with a mass fraction of 8%; turn on the peristaltic pump to make the attapulgite reduction slurry continue to flow through the magnetic separator and then return to To the reactor, circulate until the attapulgite slurry turns ...

Embodiment 2

[0020] (1) Taking Gansu brick red attapulgite clay as an example, pulverize the ore powder with a sand mill, add water to adjust the solid-to-liquid ratio of the slurry to 1:2, and adjust the pH value of the slurry with 5% sulfuric acid 3-5, mechanical stirring and soaking for 1 hour.

[0021] (2) Add the above-mentioned acidic attapulgite slurry into the enamel reaction kettle with a magnetic separator, slowly add sodium borohydride into the above-mentioned slurry under mechanical stirring, the quality of adding sodium borohydride is 8% of the mass of the attapulgite clay, continue Stir to form an attapulgite reduction slurry; start the peristaltic pump to make the attapulgite reduction slurry continue to flow through the magnetic separator and then return to the reactor, and keep the pH value of the slurry in the reaction process by dropping sulfuric acid with a mass fraction of 5% in the range of 3 to 5 ; Continue to circulate until the attapulgite slurry turns white comple...

Embodiment 3

[0023] (1) Taking Gansu brick red attapulgite clay as an example, pulverize the ore powder with a basket grinder, add water to adjust the solid-to-liquid ratio of the slurry to 1:9, and adjust the pH value of the slurry with 10% hydrochloric acid 0-3, mechanical stirring and soaking for 0.5 hours.

[0024] (2) Add the above-mentioned acidic attapulgite slurry into an enamel reaction kettle with a magnetic separator, slowly add magnesium powder into the above-mentioned slurry under mechanical stirring, the quality of the added magnesium powder is 5% of the mass of the attapulgite clay, and continue stirring to form Attapulgite reduction slurry; start the peristaltic pump to make the attapulgite reduction slurry continue to flow through the magnetic separator and then return to the reactor, and keep the pH value of the slurry between 0 and 3 during the reaction process by dropping hydrochloric acid with a mass fraction of 10% ; Continue to circulate until the attapulgite slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap