6XXX series aluminum alloy and aging process thereof

An aluminum alloy and aging technology, which is applied in the field of aluminum alloy processing to solve the scheduling problem and improve the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

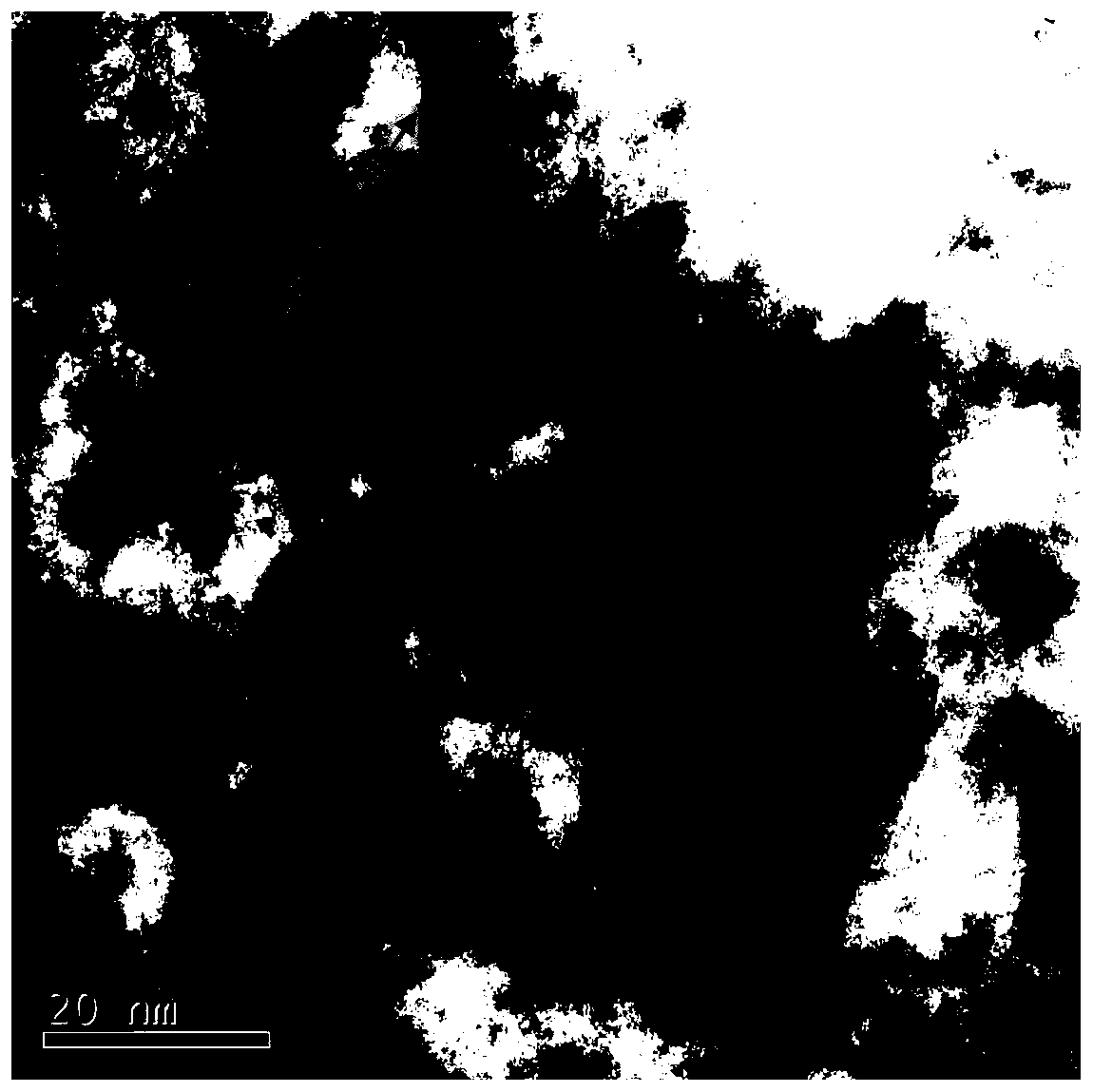

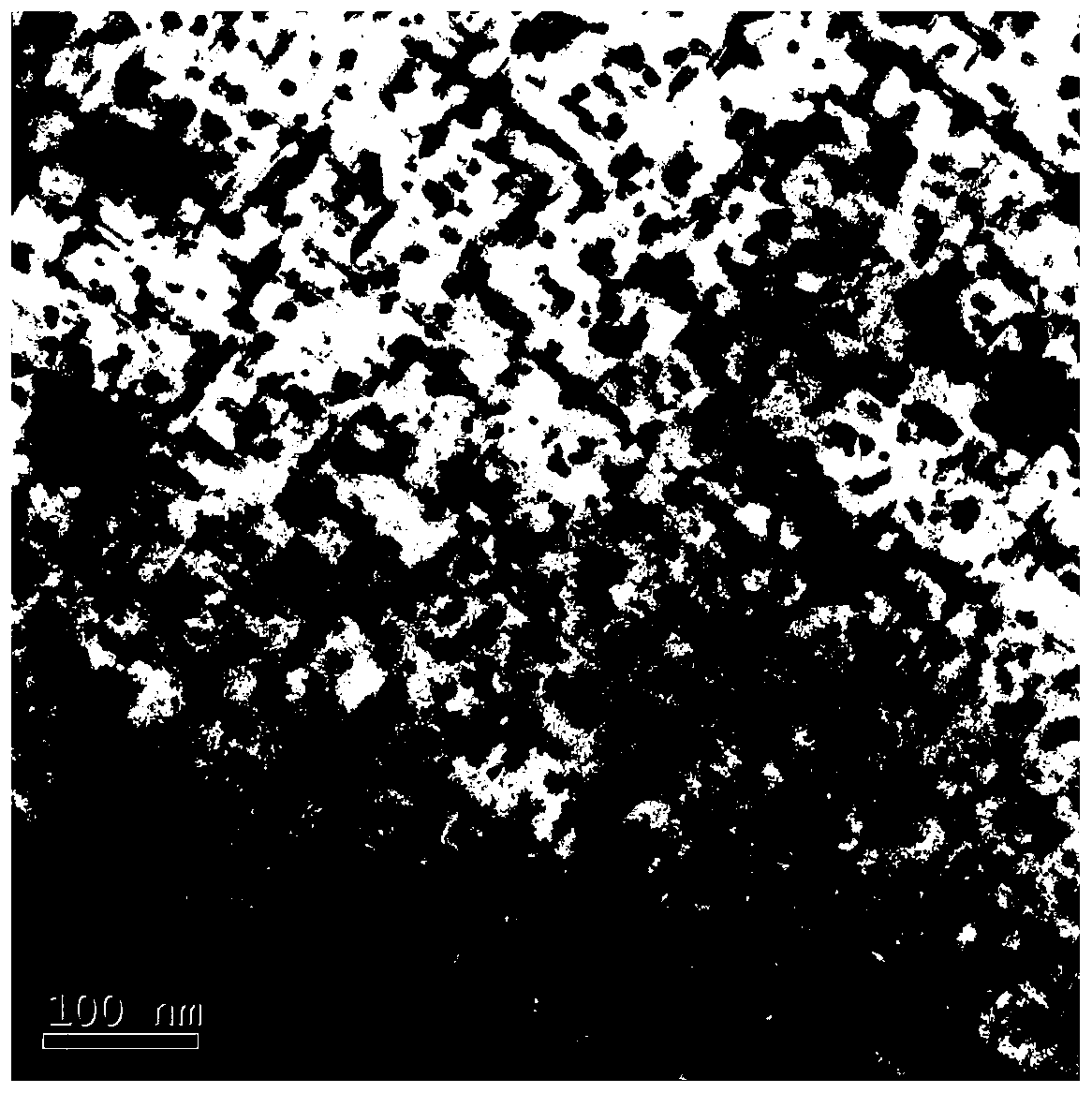

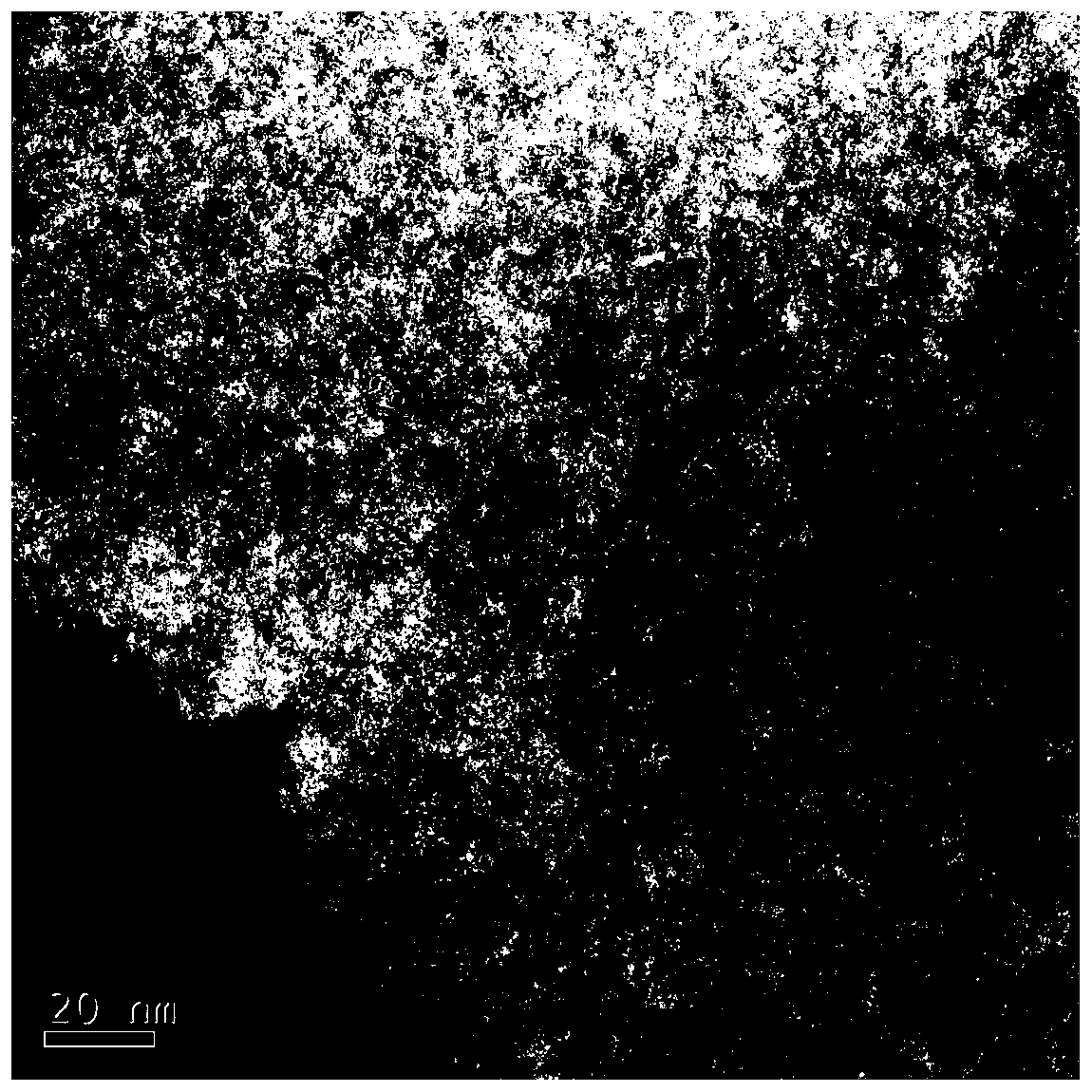

Image

Examples

Embodiment 1

[0028] This embodiment provides a preparation of an aluminum alloy extruded profile, comprising the following steps:

[0029] The composition of the aluminum alloy extrusion profile is designed as: Si: 1.4wt.%, Fe: 0.4wt.%, Cu: 0.1wt.%, Mn: 0.6wt.%, Mg: 0.7wt.%, Cr: ≤0.1wt. .%, Zn: ≤0.05wt.%, Ti: ≤0.1wt.%, the balance is Al, and the sum of the weight percentages of each component is 100%.

[0030] (1) Extrusion and quenching process:

[0031] Heat the ingot to 520°C, then extrude at a rate of 5m / min, so that the extrusion outlet temperature is about 550°C, then quench with water at room temperature online, and park for 24h;

[0032] The wall thickness of the obtained aluminum alloy extruded profile is 5 mm, and the extrusion ratio is about 20.

[0033] (2) Pre-aging treatment: after 5 hours of heat preservation at 100°C, take out of the oven and park for 7 days;

[0034] (3) Artificial aging: after holding at 175°C for 5 hours; the final mechanical properties of the obtaine...

Embodiment 2

[0038] This embodiment provides a preparation of an aluminum alloy extruded profile, comprising the following steps:

[0039] The composition of the aluminum alloy extrusion profile is designed as: Si: 1.4wt.%, Fe: 0.4wt.%, Cu: 0.1wt.%, Mn: 0.6wt.%, Mg: 0.7wt.%, Cr: ≤0.1wt. .%, Zn: ≤0.05wt.%, Ti: ≤0.1wt.%, the balance is Al, and the sum of the weight percentages of each component is 100%.

[0040] (1) Extrusion and quenching process:

[0041] Firstly, the ingot is heated to 510°C, and then extruded at a rate of 5m / min, so that the extrusion outlet temperature is about 540°C, followed by online room temperature water quenching;

[0042] The wall thickness of the obtained aluminum alloy extruded profile is 5 mm, and the extrusion ratio is about 20.

[0043] (2) Pre-aging treatment: Pre-aging immediately after quenching, after 3 hours of heat preservation at 120°C;

[0044] (3) Artificial aging: heat preservation at 175°C for 5 hours; the final mechanical properties of the obt...

Embodiment 3

[0046] This embodiment provides a preparation of an aluminum alloy extruded profile, comprising the following steps:

[0047] The composition of the aluminum alloy extrusion profile is designed as: Si: 1.1wt.%, Fe: 0.18wt.%, Cu: 0.04wt.%, Mn: 0.62wt.%, Mg: 0.77wt.%, Cr: ≤0.1wt. .%, Zn: ≤0.05wt.%, Ti: ≤0.1wt.%, the balance is Al, and the sum of the weight percentages of each component is 100%;

[0048] (1) Extrusion and quenching process:

[0049] Firstly, the ingot is heated to 510°C, and then extruded at a rate of 5m / min, so that the extrusion outlet temperature is about 540°C, followed by online room temperature water quenching;

[0050]The wall thickness of the obtained aluminum alloy extruded profile is 5 mm, and the extrusion ratio is about 20.

[0051] (2) Pre-aging treatment: Pre-aging immediately after quenching, after 120 ° C for 3 hours, park for 15 days;

[0052] (3) Artificial aging: heat preservation at 175°C for 7 hours; the final mechanical properties of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com