Scroll compressor and refrigerating system

A scroll compressor and scroll technology, applied in the field of compressors, can solve problems such as noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

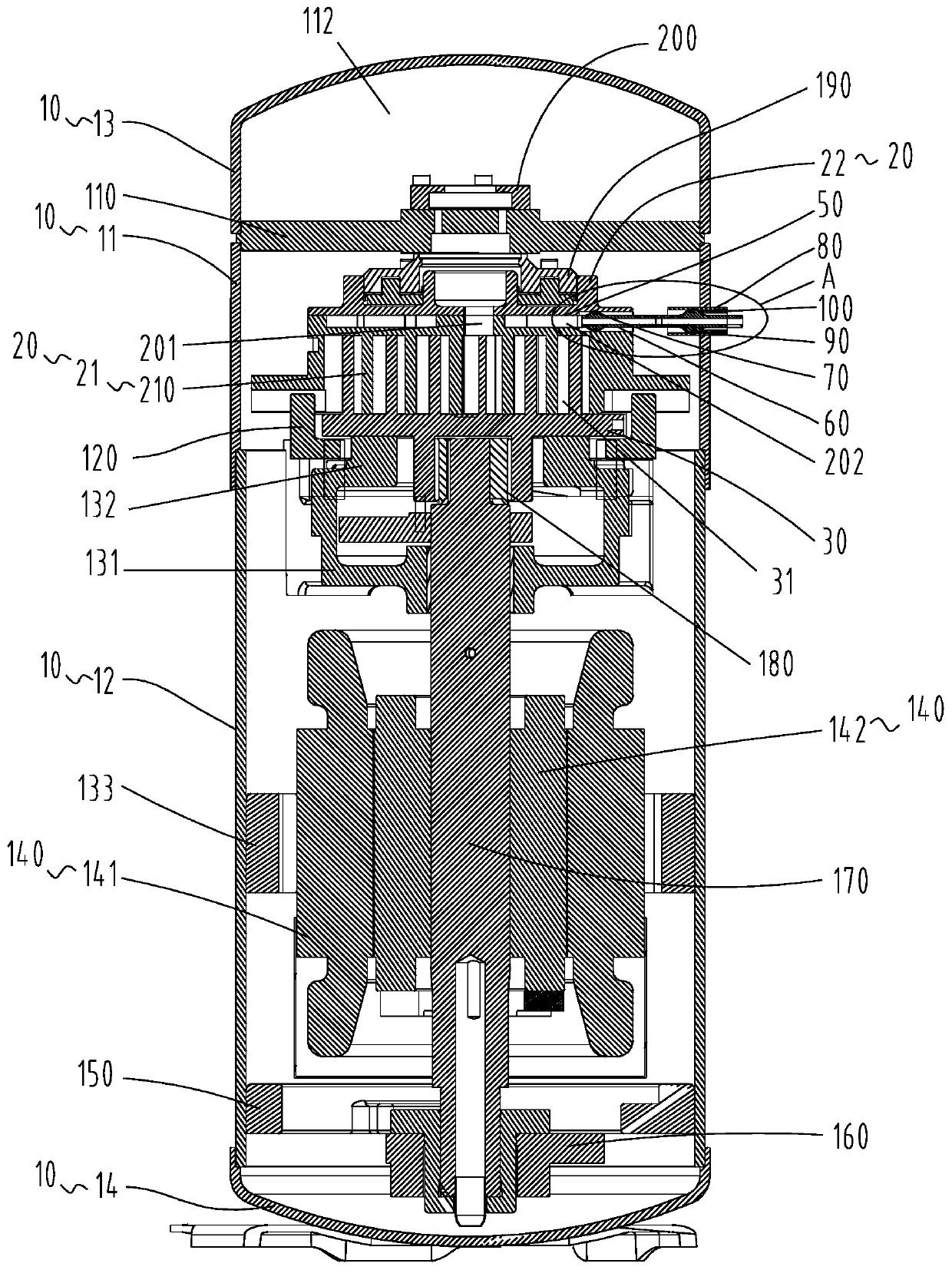

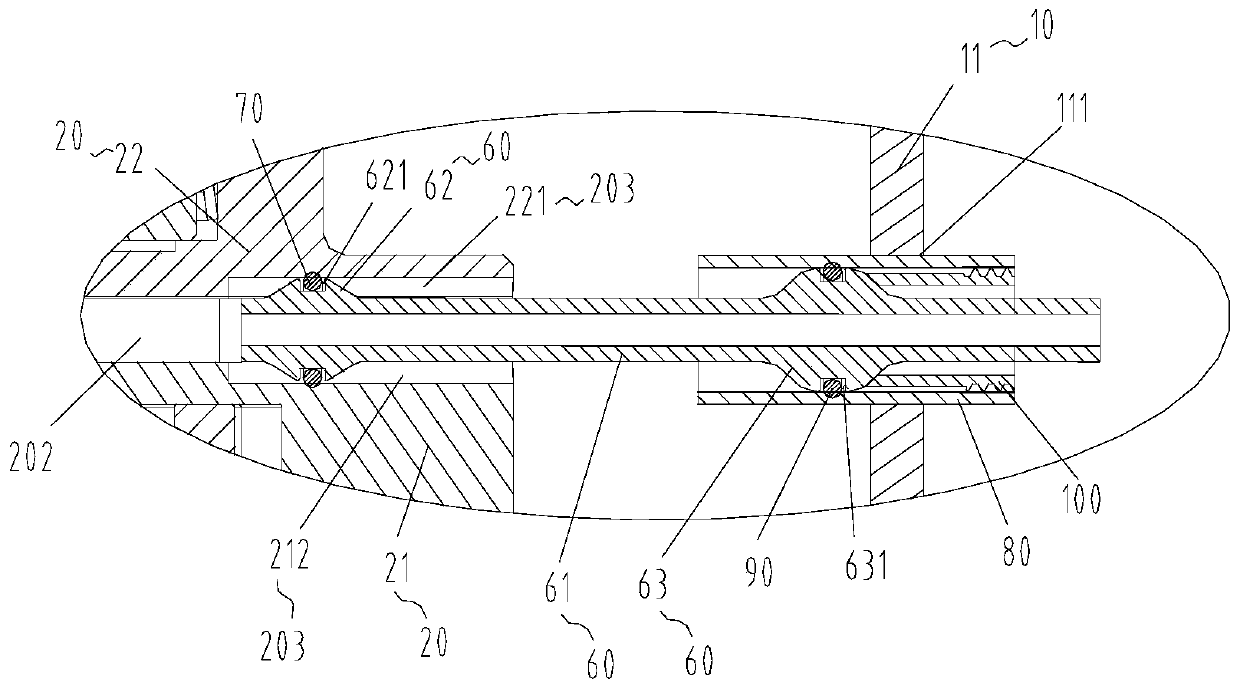

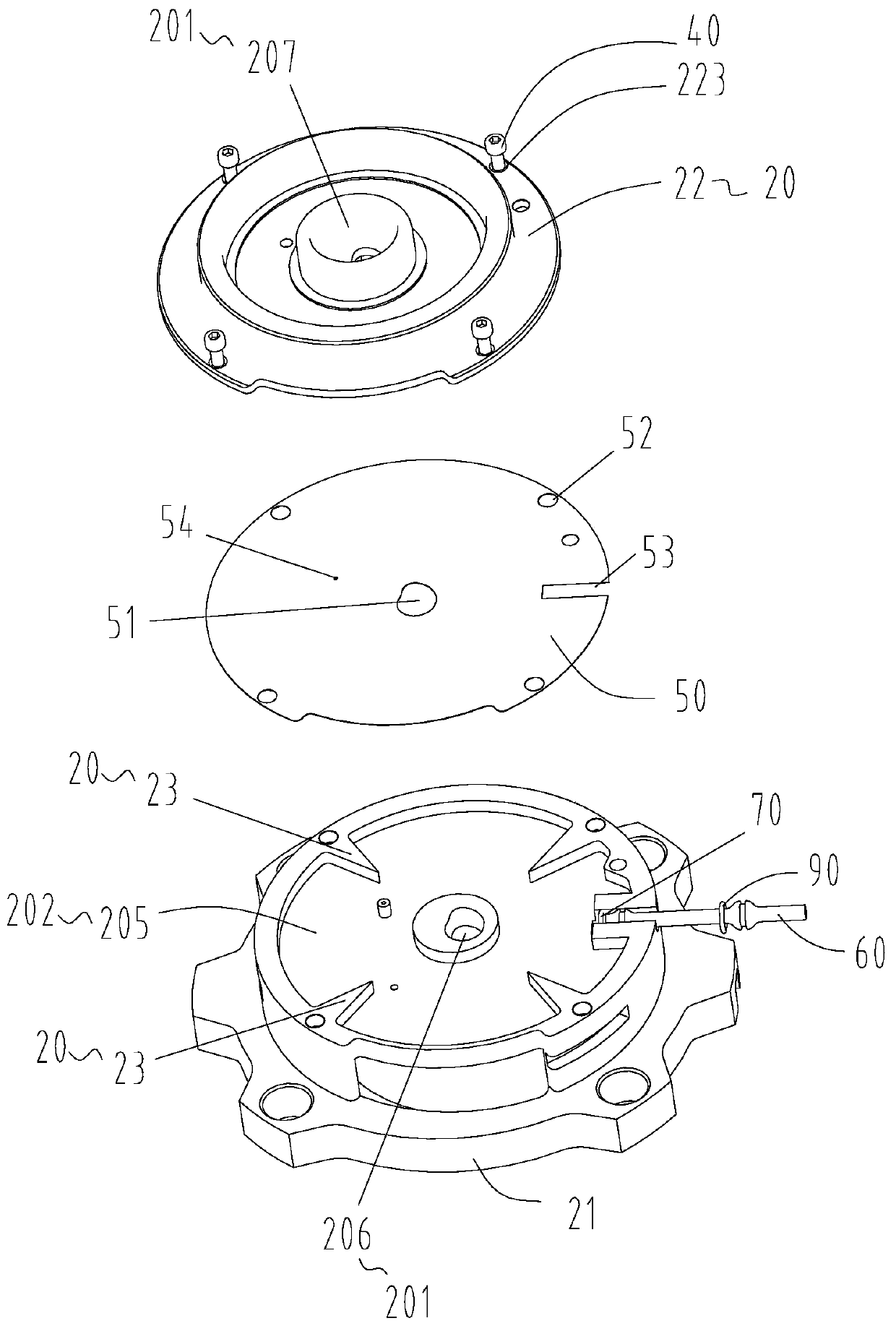

[0039] Such as Figure 1 to Figure 5 As shown, the scroll compressor includes a casing 10, a fixed scroll 20 and a movable scroll 30, the fixed scroll 20 is arranged in the casing 10, the movable scroll 30 is movably arranged in the fixed scroll 20, and the fixed scroll 20 A scroll cavity 31 is formed between the movable scroll 30; the fixed scroll 20 has an exhaust channel 201 for communicating with the scroll cavity 31, and the fixed scroll 20 has a muffler cavity 202 arranged around the periphery of the exhaust channel 201, The silencer chamber 202 and the exhaust passage 201 are arranged at intervals; wherein, the static scroll 20 is provided with an intake passage 203 communicating with the silencer chamber 202 , and the static scroll 20 is provided with a passageway connected with the silencer chamber 202 and the scroll chamber 31 Air intake hole 204 .

[0040] In this embodiment, the structure of the fixed scroll 20 is changed, thereby changing the circulation path of ...

Embodiment 2

[0070] The difference between the second embodiment and the first embodiment is only that the shape and size of the muffler cavity 202 are different. Such as Figure 6 As shown, the projection of the outer peripheral wall of the muffler cavity 202 on the radial section of the fixed scroll 20 includes a curved line segment and a third straight line segment 215, and the curved line segment includes a plurality of second circular arc line segments 213 connected in sequence, and each second circle The arc segments 213 protrude toward the side of the inner peripheral wall of the muffler chamber 202, and the two ends of the third straight segment 215 are respectively connected to the two ends of the curved segment; wherein, the intake passage 203 and the third straight segment 215 are located in the exhaust passage On the same side as 201 , the centerline of the intake passage 203 passes through the midpoint of the third straight line segment 215 . In this embodiment, through the a...

Embodiment 3

[0076] The difference between the third embodiment and the first embodiment is only that the shape and size of the muffler cavity 202 are different. Such as Figure 7 As shown, the projection of the outer peripheral wall of the muffler cavity 202 on the radial section of the fixed scroll 20 includes a third circular arc line segment 216 and a fourth straight line segment 217 opposite to each other, and a first curved line segment 218 and a second curved line segment 218 opposite to each other. Curved segment 219, the two ends of the first curved segment 218 are respectively connected with the first end of the third circular arc segment 216 and the first end of the fourth straight segment 217; the two ends of the second curved segment 219 are connected with the third circular arc respectively The second end of the line segment 216 is connected with the second end of the fourth straight segment 217; wherein, the intake passage 203 and the fourth straight segment 217 are located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com