Sample punching machine and sample punching mold thereof

A mold and sample punching technology, which is applied in the field of sample punching machines and sample punching molds, can solve the problems of high frequency of mold damage, waste of punching needles, and high maintenance costs of equipment, so as to reduce the frequency of mold damage, avoid waste of punching needles, and reduce equipment. The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

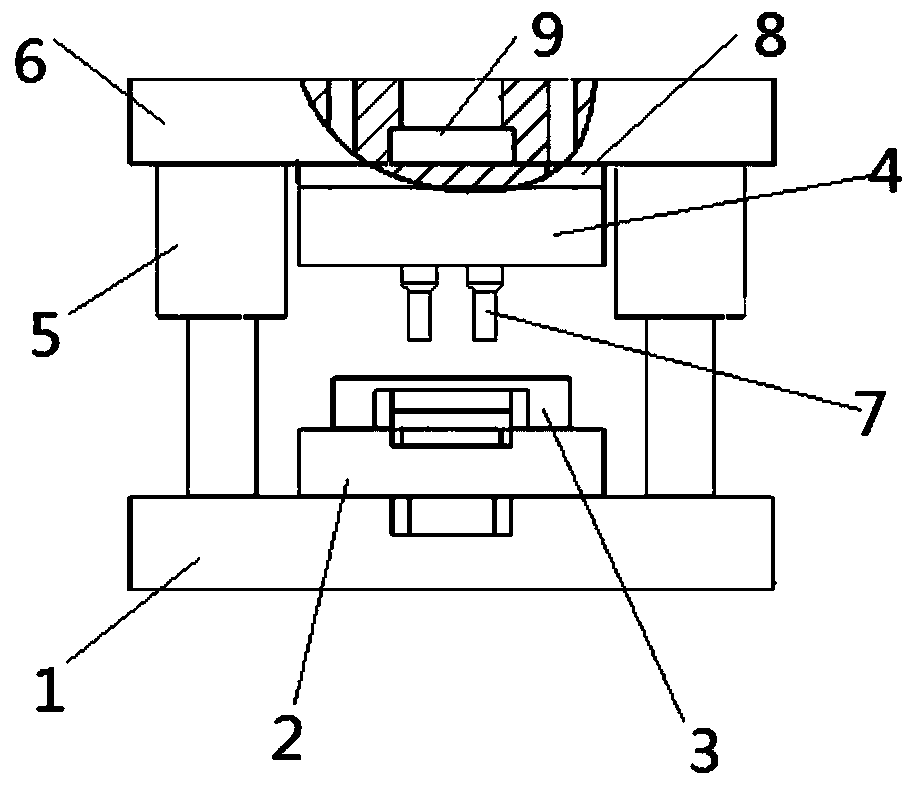

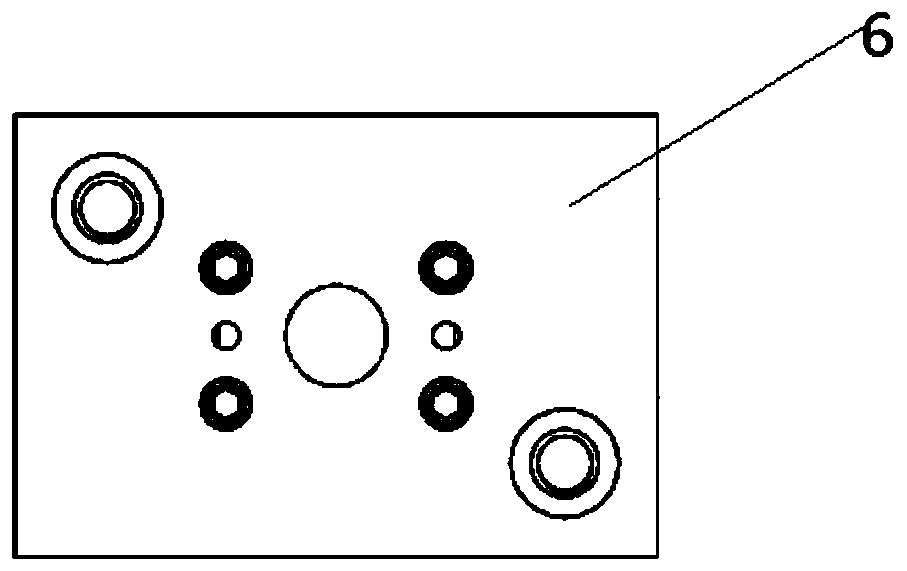

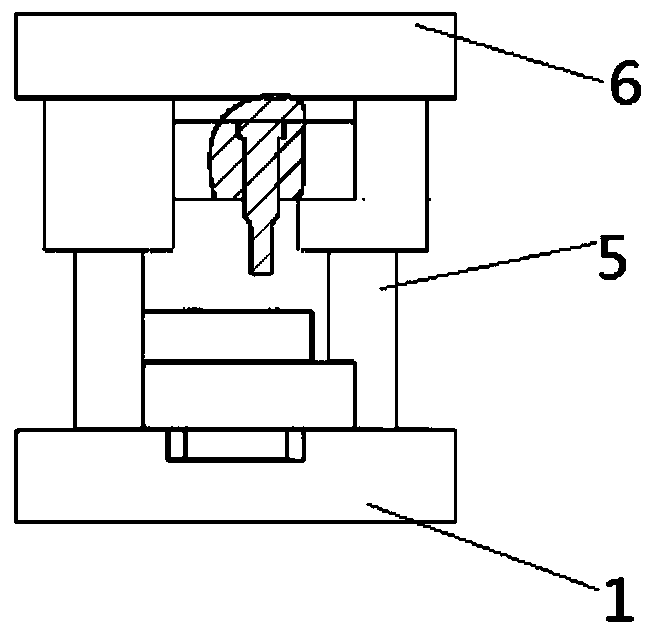

[0044] This embodiment provides a punching mold, please refer to figure 1 , The punching mold includes: a base 1.

[0045] Specifically, the base 1 is a die support structure of the punching die, that is, the base 1 provides support for the die 2 and the base 1 can be used to fix the die to facilitate punching processing. Such as Figure 4 , 5 As shown in Fig. 6, in this embodiment, the shape of the base 1 is a rectangular parallelepiped structure. In actual use, the installation design can also be carried out as required, and there is no specific limitation in this embodiment. In addition, a plurality of bolt holes are opened on the base 1 for installing screws and other connecting parts. In this embodiment, it is preferable that the material of the base 1 is 45 steel and the hardness is HRC32-36. Among them, 45 steel represents high-quality carbon structural steel with a carbon content of 0.42 to 0.50%. 45 steel is a high-quality carbon structural steel with low hardness and ...

Embodiment 2

[0067] This embodiment also provides a punching machine, including the aforementioned punching die.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com