Fault detection method and system for complex process considering dynamic relationship in advance

A fault detection and dynamic technology, applied in the general control system, control/regulation system, program control, etc., can solve the problem of no detection method and achieve a strong and robust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

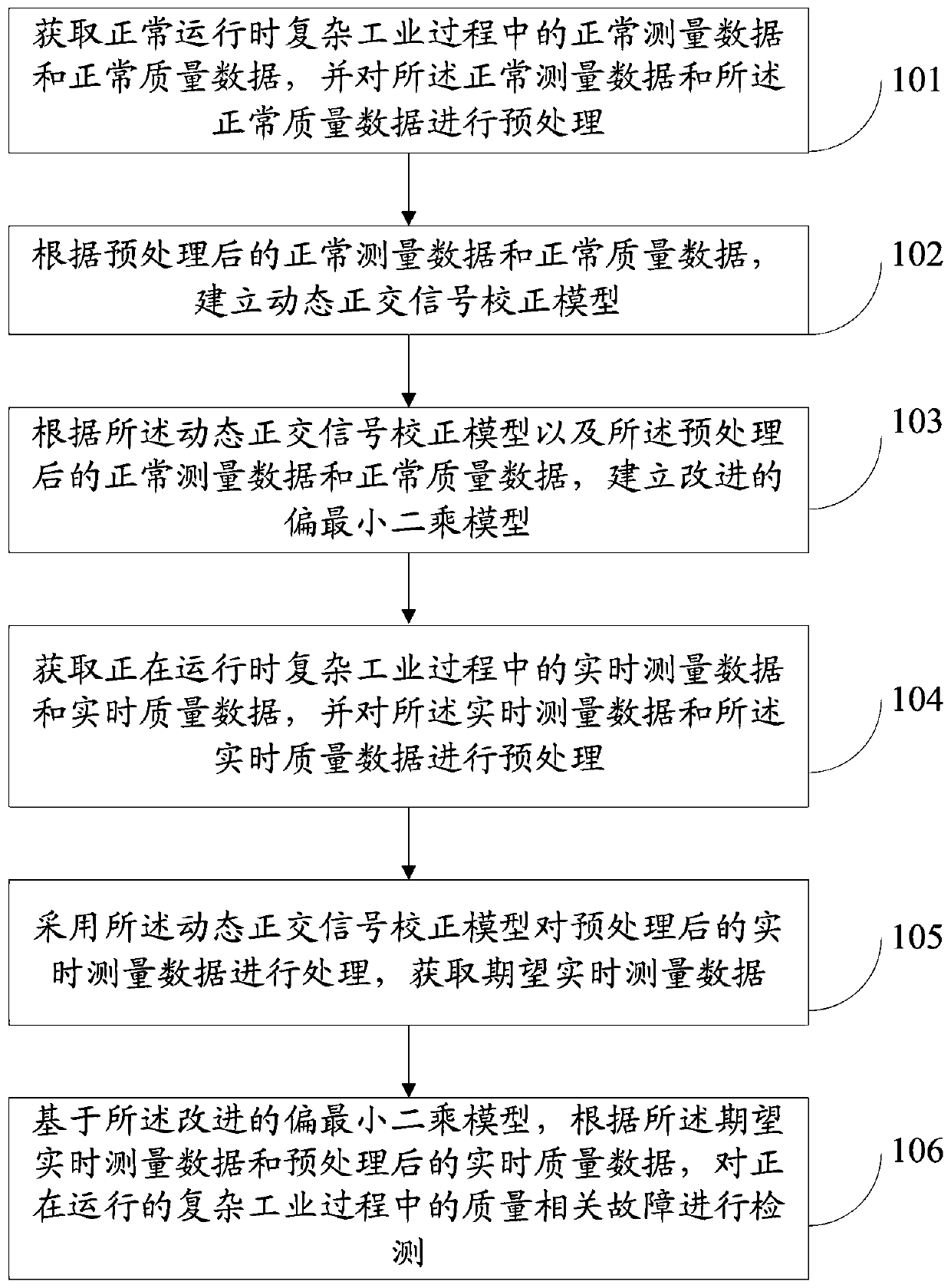

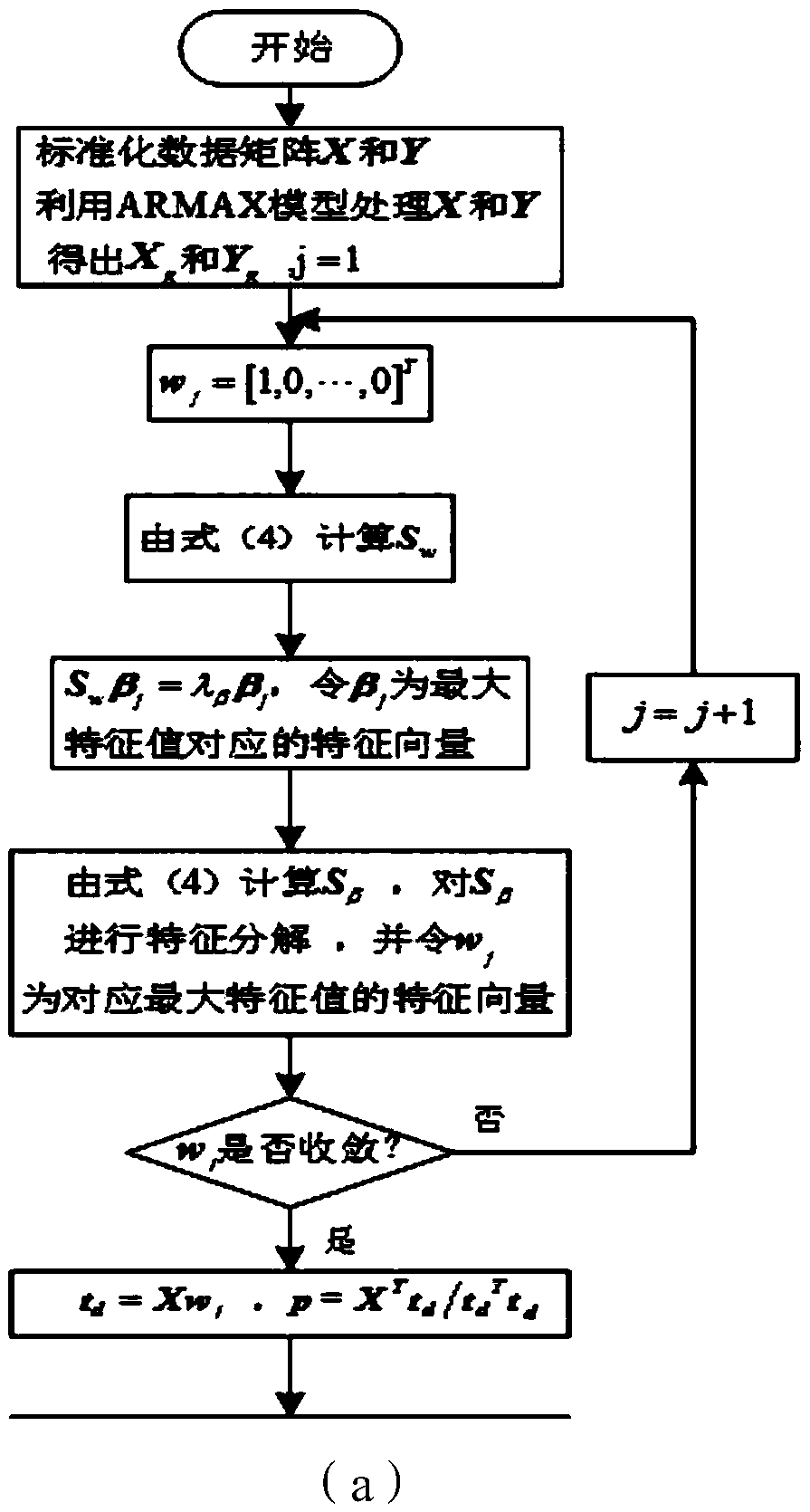

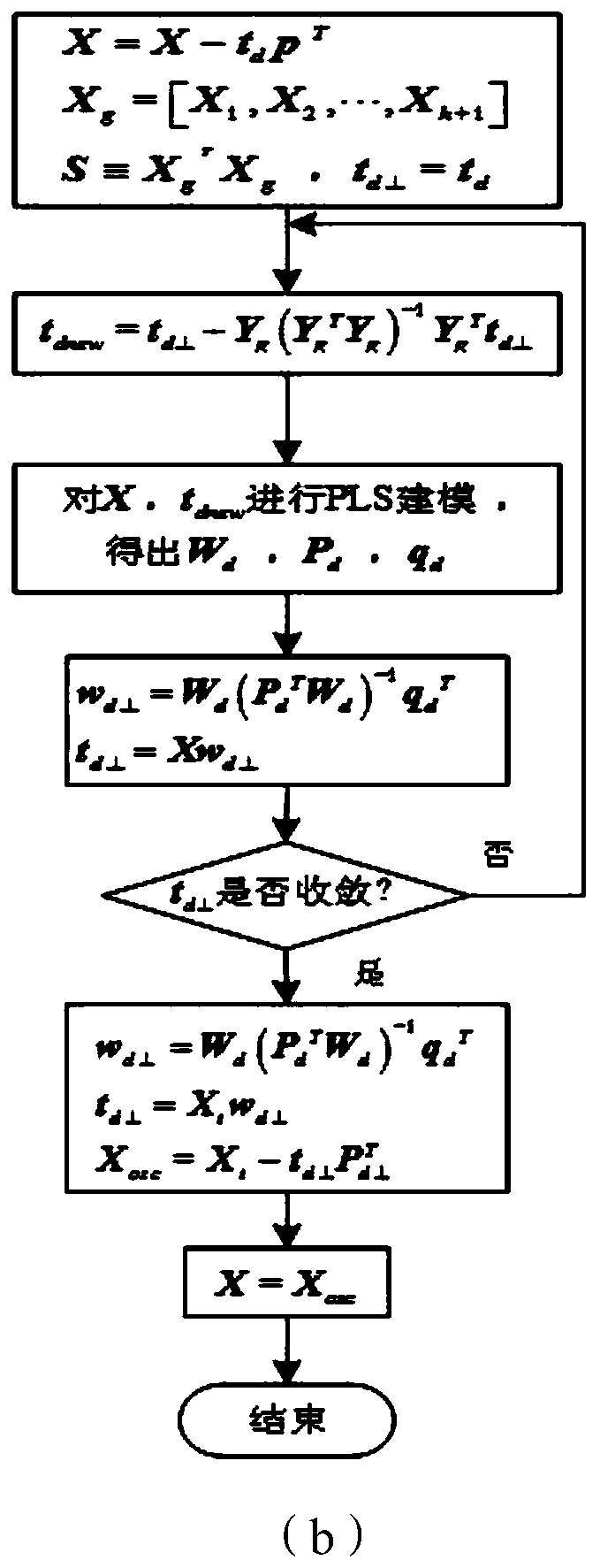

[0081] figure 1 The flow chart of the fault detection method for the complex process of pre-considering the dynamic relationship in Embodiment 1 of the present invention, such as figure 1 As shown, the present embodiment provides a fault detection method for a complex process that considers dynamic relationships in advance, including the following steps:

[0082] Step 101: Obtain normal measurement data and normal quality data in a complex industrial process during normal operation, and perform preprocessing on the normal measurement data and the normal quality data.

[0083] Step 102: Establish a dynamic orthogonal signal correction model according to the preprocessed normal measurement data and normal quality data.

[0084] For a complex industrial process with normal operation, m sensors are used to detect its key input variables (such as flow, pressure, liquid level, temperature, etc.) n times, which is called normal measurement data, and the normal measurement data set i...

Embodiment 2

[0142] In order to achieve the above object, the present invention also provides a fault detection system that considers the complex process of dynamic relationship in advance, such as image 3 shown, including:

[0143] The first preprocessing module 201 is configured to acquire normal measurement data and normal quality data in complex industrial processes during normal operation, and perform preprocessing on the normal measurement data and the normal quality data.

[0144] The dynamic quadrature signal correction model establishment module 202 is used to establish a dynamic quadrature signal correction model according to the preprocessed normal measurement data and normal quality data.

[0145] The improved partial least squares model establishment module 203 is configured to establish an improved partial least squares model according to the dynamic orthogonal signal correction model and the preprocessed normal measurement data and normal quality data.

[0146] The second ...

Embodiment 3

[0174] The present invention verifies the performance of the proposed algorithm through the built Tennessee Eastman Process, which is an important platform for algorithm performance testing and evaluation, and also an important data source for multivariate process monitoring method testing. The TE process contains many measured variables, manipulated variables, output variables and disturbances, etc. It is a typical complex industrial process. Its rich degrees of freedom can provide many researchers engaged in algorithm development with precious and massive test data, and it is widely used in the field of fault detection and fault diagnosis in industrial processes.

[0175] The Tennessee Eastman Process was created by Eastman Chemical Company to provide a realistic industrial process for evaluating process control and monitoring methods. The process consists of five main units: reactor, condenser, compressor, separator, and stripper, and it contains eight components: A, B, C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com