Permanent magnet synchronous motor

A permanent magnet synchronous motor, No. 1 technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of poor motor stability, low starting torque, low release efficiency, etc., and achieves convenient manufacturing technology and large starting torque. , the effect of accelerating the decline of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

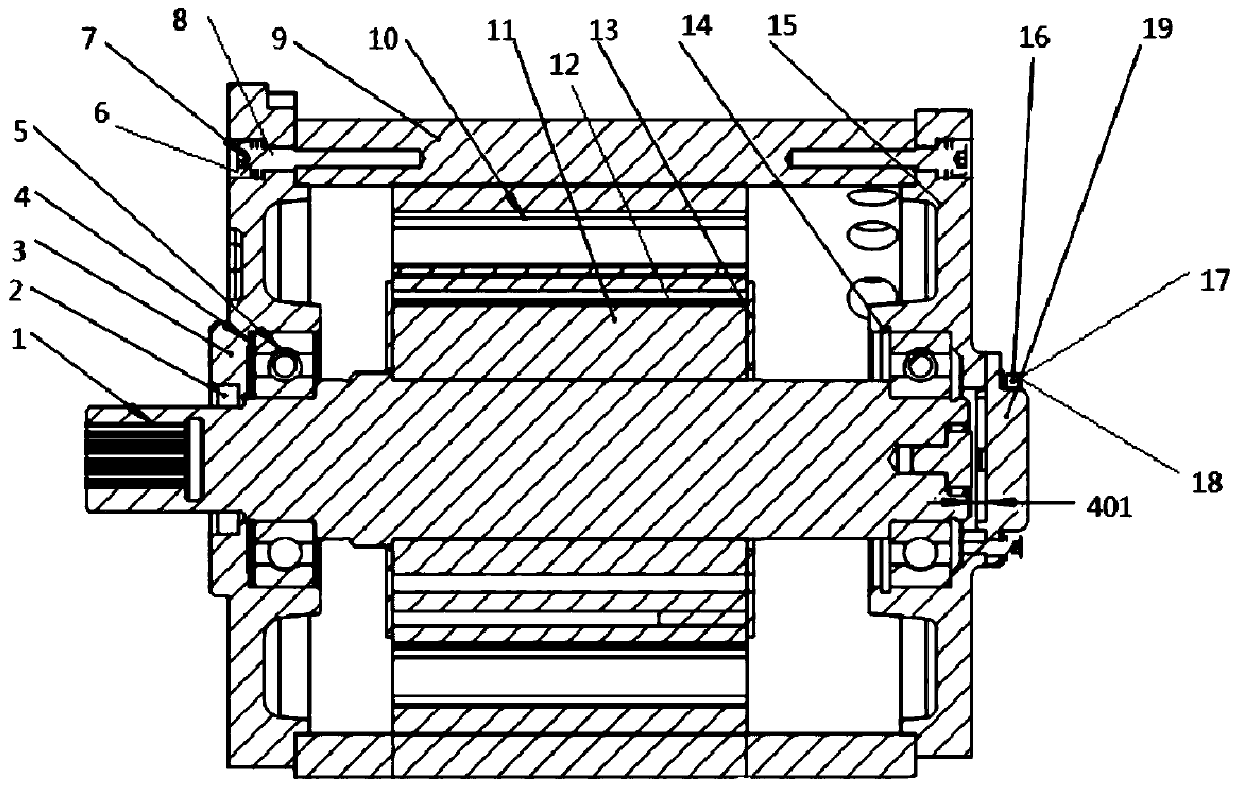

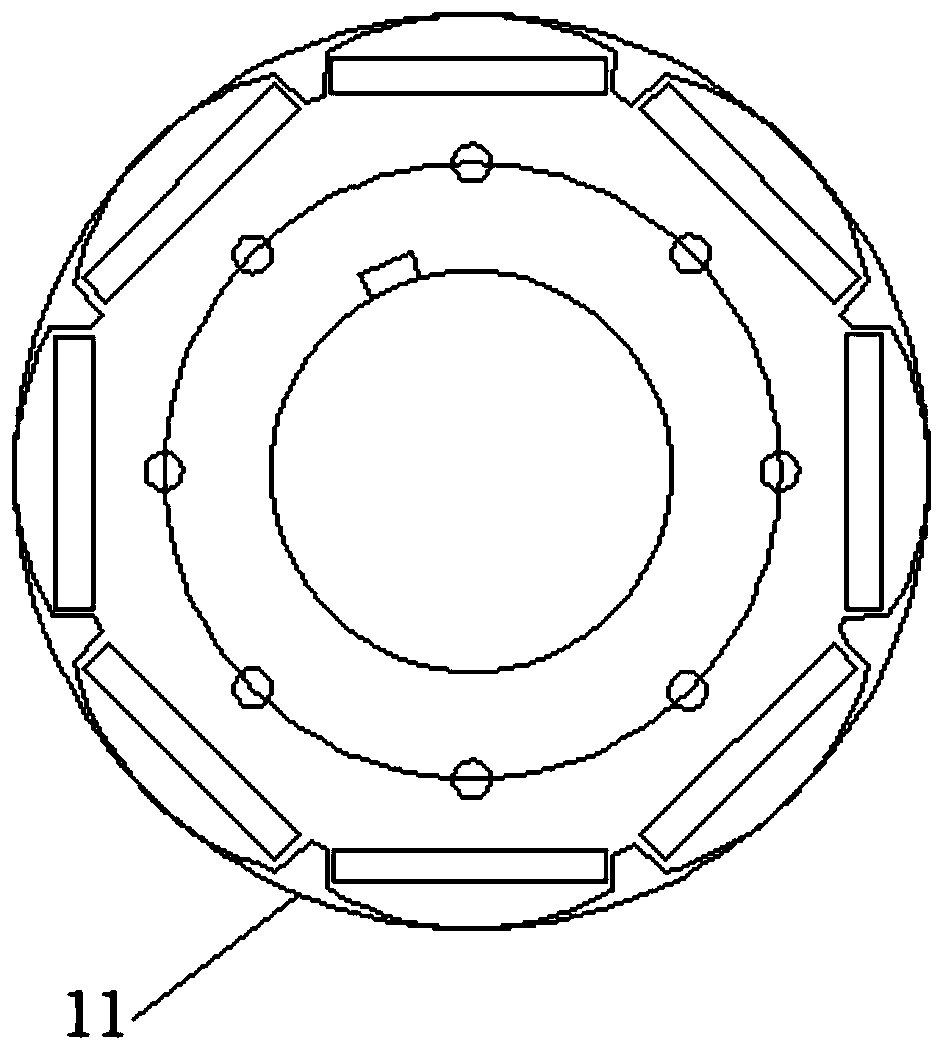

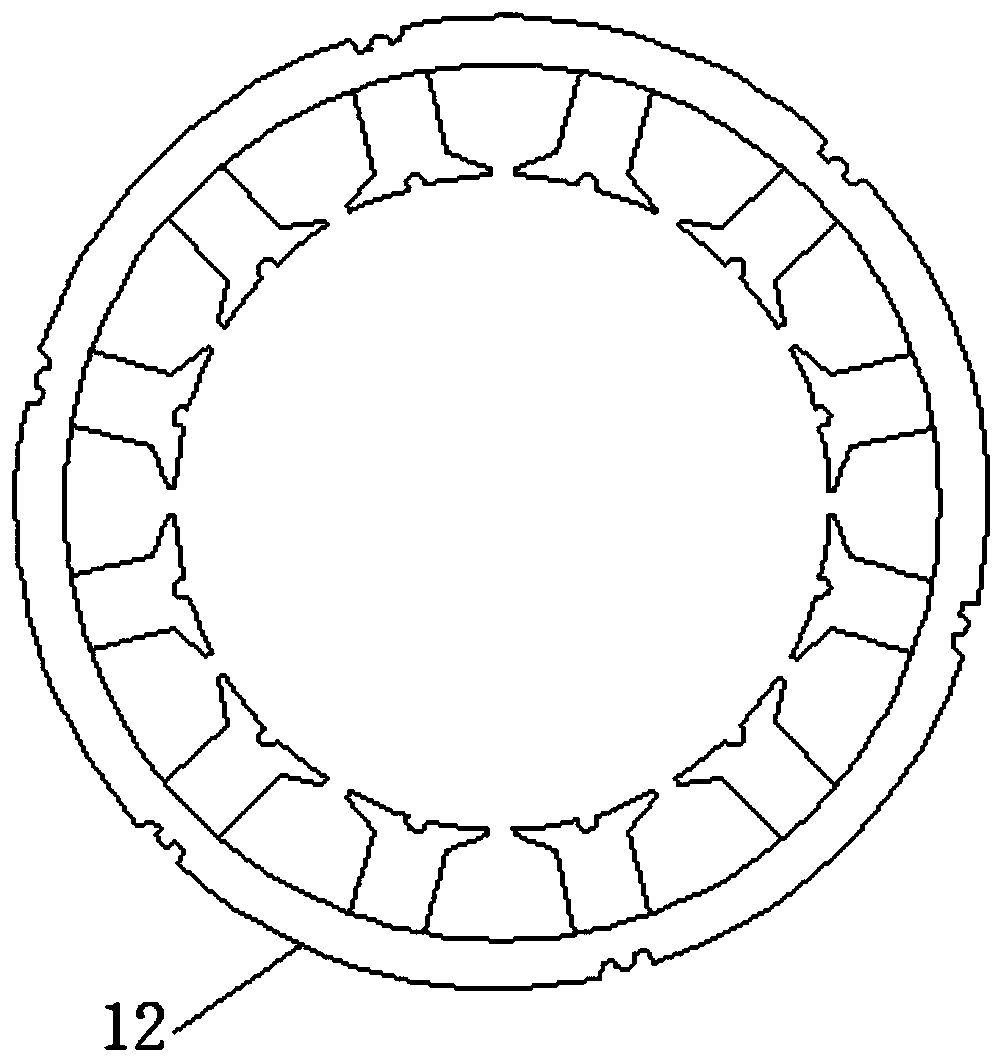

[0027] A permanent magnet synchronous motor, comprising a rotating shaft 1, an end cover 3, a base 9 and a rear cover 15, the two ends of the base 9 are respectively detachably connected with an end cover 3 and a rear cover 15, and the rotating shaft 1 is plugged in Inside the base 9, and the transmission output end of the rotating shaft 1 protrudes from the end cover 3, the inside of the base 9 is respectively equipped with a winding stator 10, a permanent magnet 11 and a rotor core 12, the permanent magnet 11 and the rotor core 12 Located inside the winding stator 10.

[0028] The end cover 3 is detachably connected to the base 9 through the No. 1 fastener 6, the No. 2 fastener 7 and the No. 3 fastener 8 respectively, and the No. 1 fastener 6, the No. The No. 3 fastener 8 facilitates the installation and removal of the end cover 3 and the base 9 .

[0029] A rotating shaft lip seal ring 2 is installed at the joint between the rotating shaft 1 and the end cover 3 , and the w...

Embodiment 2

[0036] A permanent magnet synchronous motor, comprising a rotating shaft 1, an end cover 3, a base 9 and a rear cover 15, the two ends of the base 9 are respectively detachably connected with an end cover 3 and a rear cover 15, and the rotating shaft 1 is plugged in Inside the base 9, and the transmission output end of the rotating shaft 1 protrudes from the end cover 3, the inside of the base 9 is respectively equipped with a winding stator 10, a permanent magnet 11 and a rotor core 12, the permanent magnet 11 and the rotor core 12 Located inside the winding stator 10.

[0037] The end cover 3 is detachably connected to the base 9 through the No. 1 fastener 6, the No. 2 fastener 7 and the No. 3 fastener 8 respectively, and the No. 1 fastener 6, the No. The No. 3 fastener 8 facilitates the installation and removal of the end cover 3 and the base 9 .

[0038] A rotating shaft lip seal ring 2 is installed at the joint between the rotating shaft 1 and the end cover 3 , and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com