Multi-stage sedimentation rake-free concentration device comprising layer-drop diversion sedimentation screen

A technology of thickening device and settling tank, which is applied in the feeding/discharging device of settling tank, settling tank, dehydration/drying/concentrated sludge treatment, etc. It can solve the impact of coal washing quality, fine sludge cannot be effectively removed, Problems such as poor settling effect can be achieved to improve the deterioration of the washing process, accelerate adhesion, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

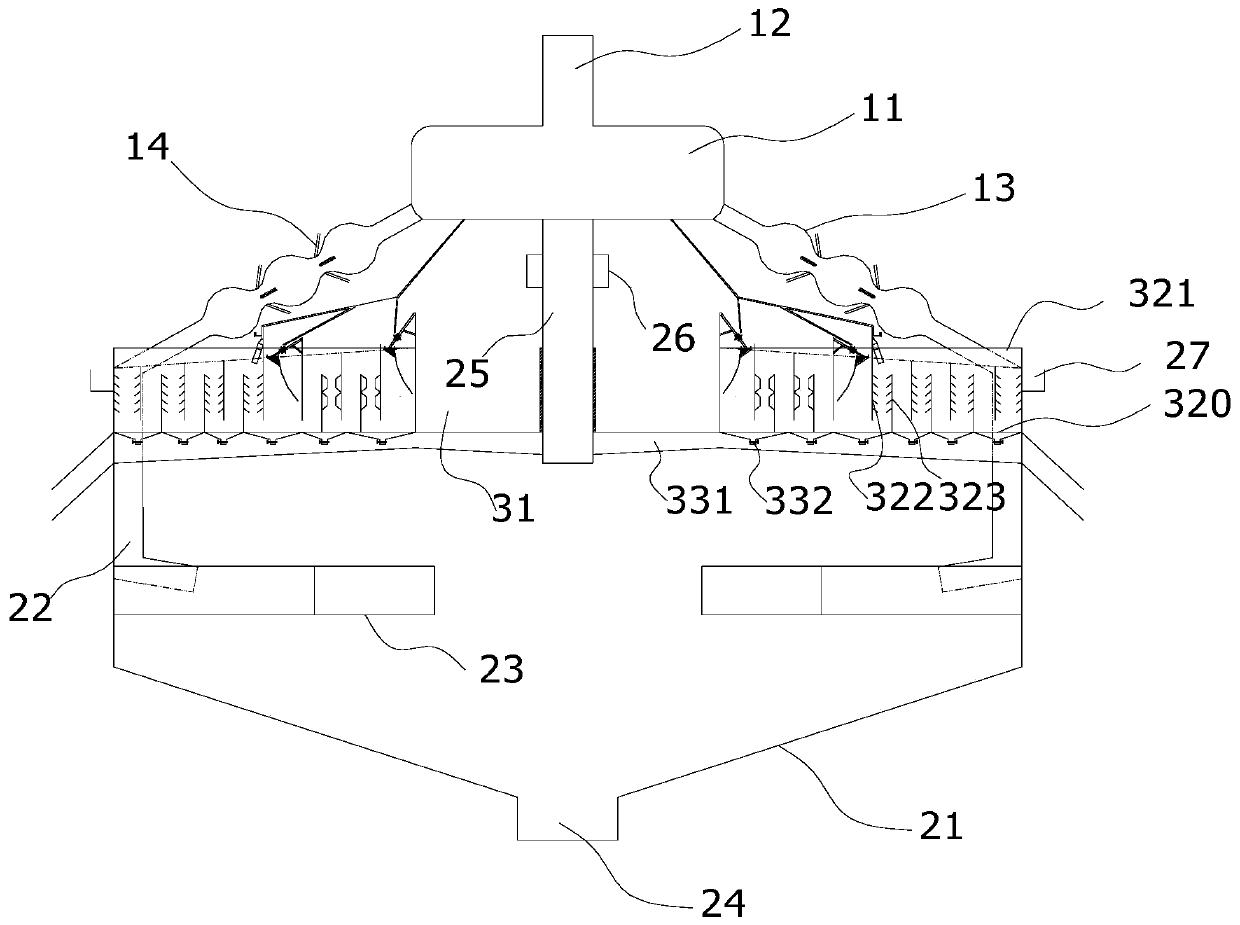

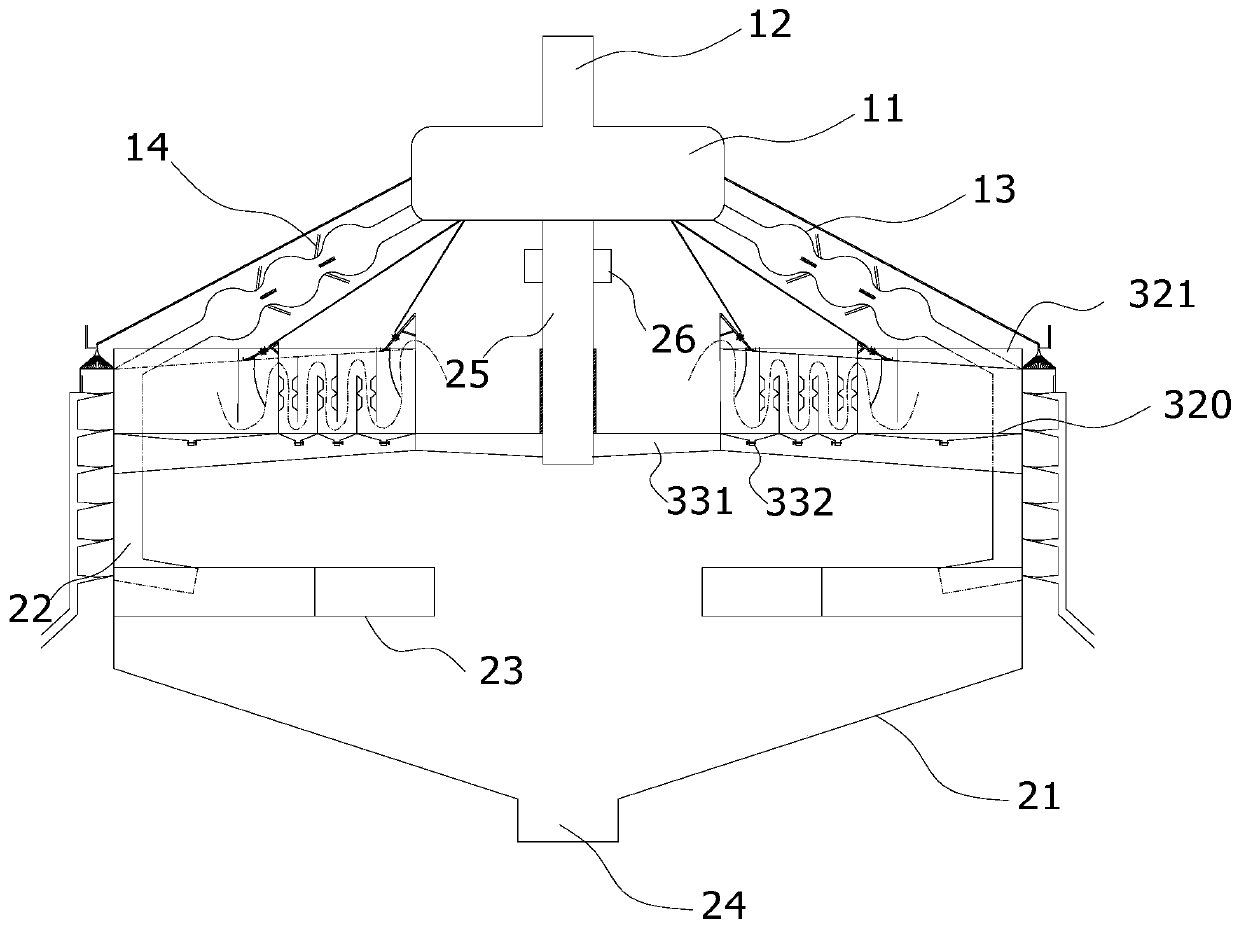

[0047] A multi-stage subsidence non-rake thickening device comprising a layered flow diversion sedimentation screen, including a feeding assembly, a flow diversion assembly, and a clean coal collection assembly. The guide assembly includes a central tank 21 with a cylindrical portion at the upper end and a funnel at the lower end. The central tank 21 is a cavity structure, and the feeding assembly is arranged above the cavity of the central tank 21. The central tank The lower end of the body 21 is provided with a first discharge port 24 . The coarse coal slime gradually settles to the top of the first discharge port 24 of the central tank 21 and deposits to a certain amount, and is discharged through the first discharge port 24, and the material discharged from the first discharge port 24 is collected , used for medium coal blending or as building materials to increase economic income.

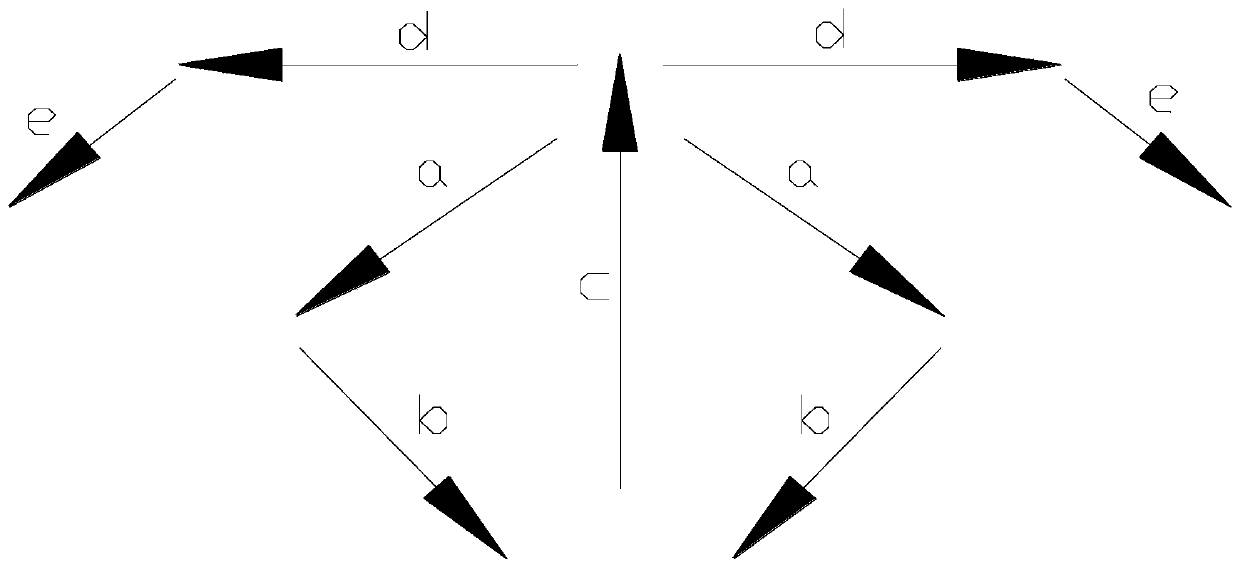

[0048] Such as figure 1 As shown, the materials and medicaments enter the guide assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com