Inverter compressor and semiconductor chilling plate two-in-one flue gas pretreatment condenser

A variable frequency compressor, semiconductor technology, applied in gas treatment, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of wasting electric energy resources, poor refrigeration and dehumidification effect, high cost, etc., and achieves easy setting and operation, reducing condensation The effect of water adsorption and component loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

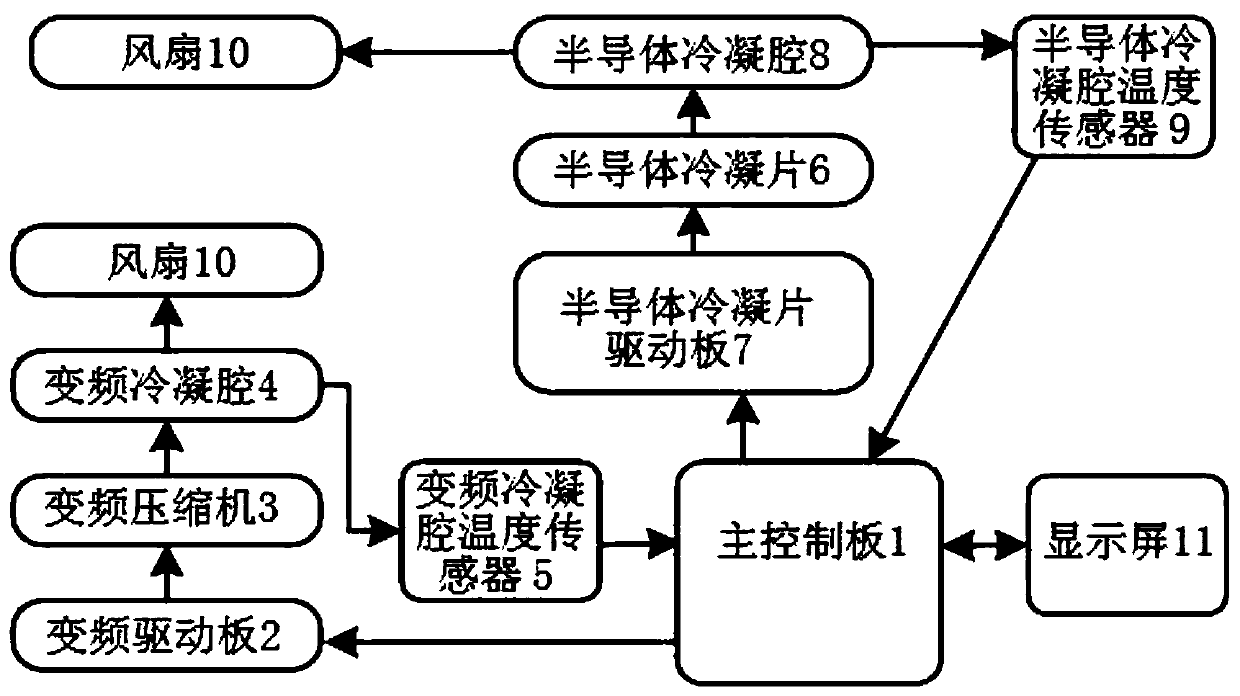

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

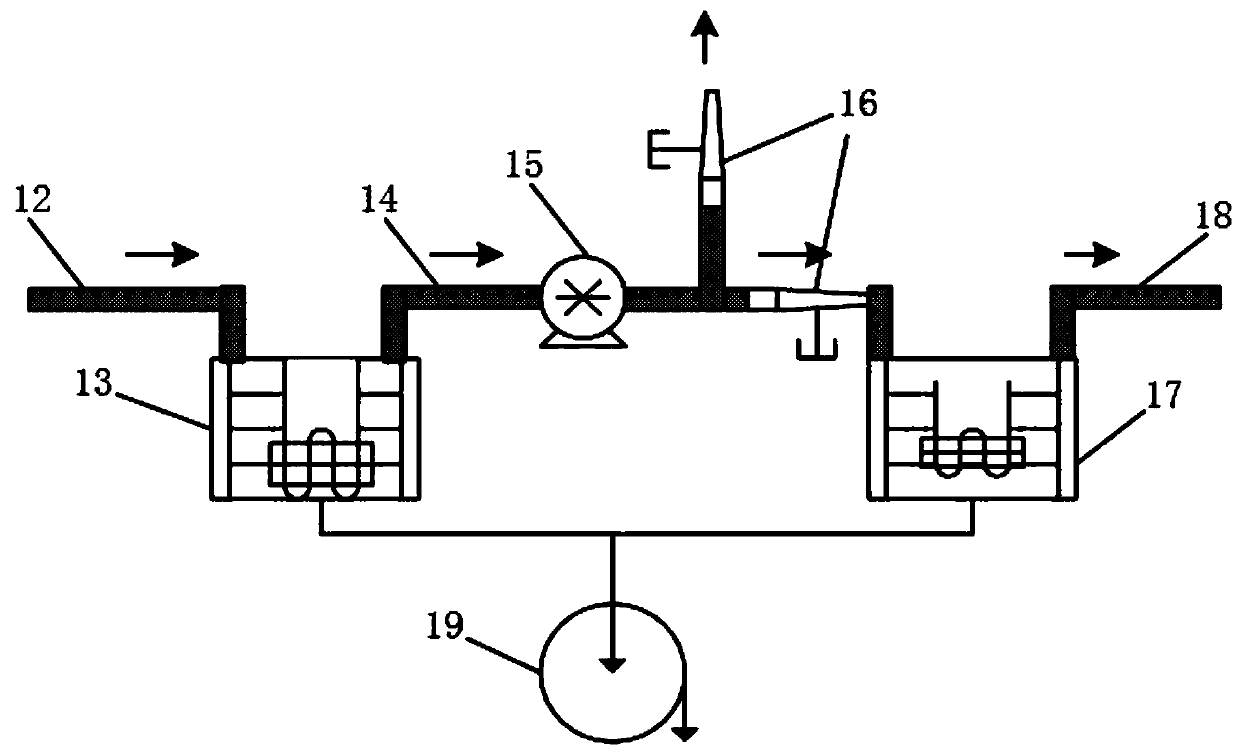

[0031] Embodiment 1: With reference to the functional structure diagram shown in 2, after the large flow rate (about 5L / min) air pump 15 is started, the flue gas sampler extracts flue gas from the flue, and is connected to the variable frequency condenser through the heat tracing sampling line 12 13. After the first stage of rough condensation and dehumidification treatment, it is discharged through the first air pipe 14 to the air inlet of the air pump 15; the air outlet of the air pump 15 is connected to two rotameters 16. After adjustment, about 1L / min of smoke flows into the semiconductor condensation 17, and most of the remaining flue gas is emptied after passing through the rotameter 16, because the humidity of the flue gas after the first-stage dehumidification is not high, it can be emptied directly; the flue gas of about 1L / min is dehumidified by the semiconductor condenser 17 It is discharged to the analytical instrument behind through the second air pipe 18; during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com