Device for recovering drilling cuttings through air exhaust

A technology of drill cuttings and recovery ports, which is applied in the field of powder collection and management, can solve the problem of not being able to collect all drill cuttings, and achieve the effects of simple device structure, effective collection, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

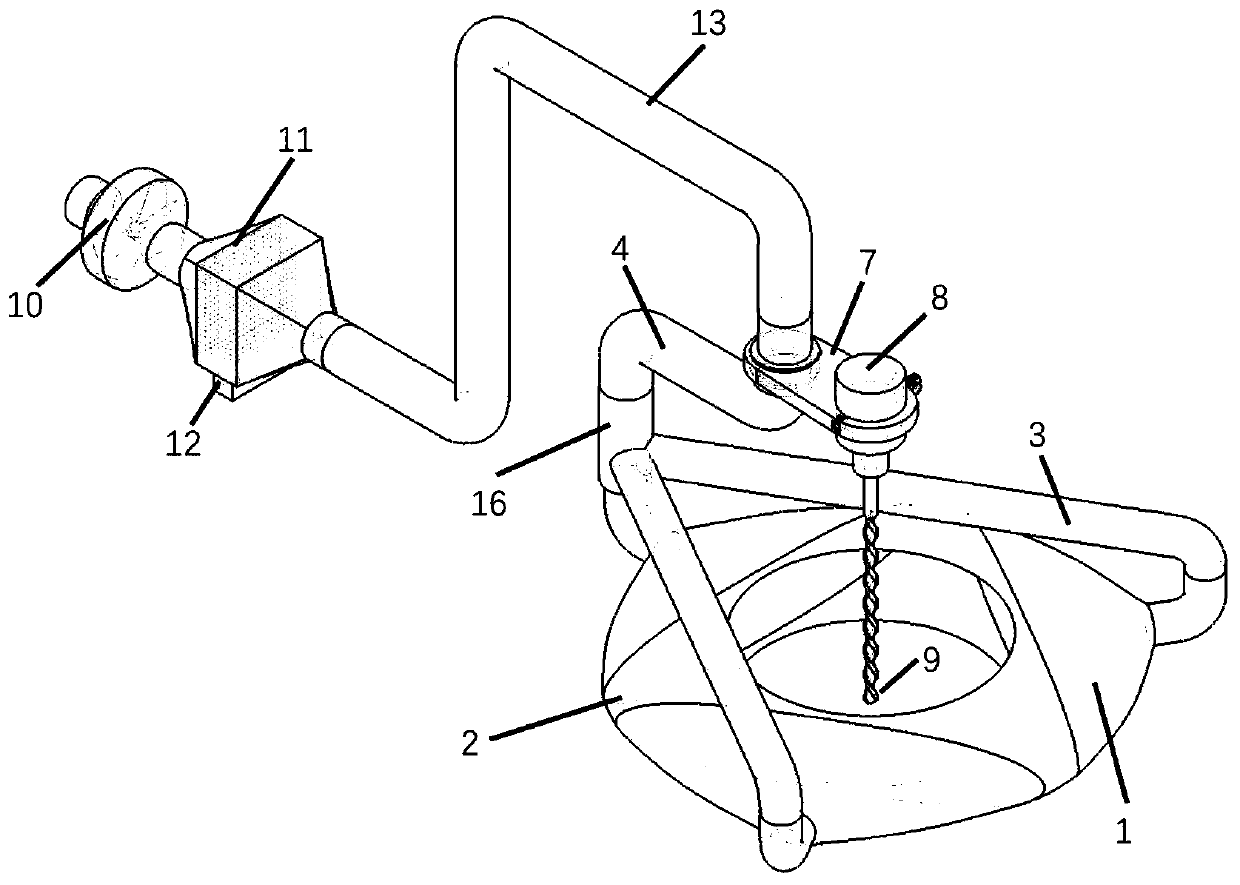

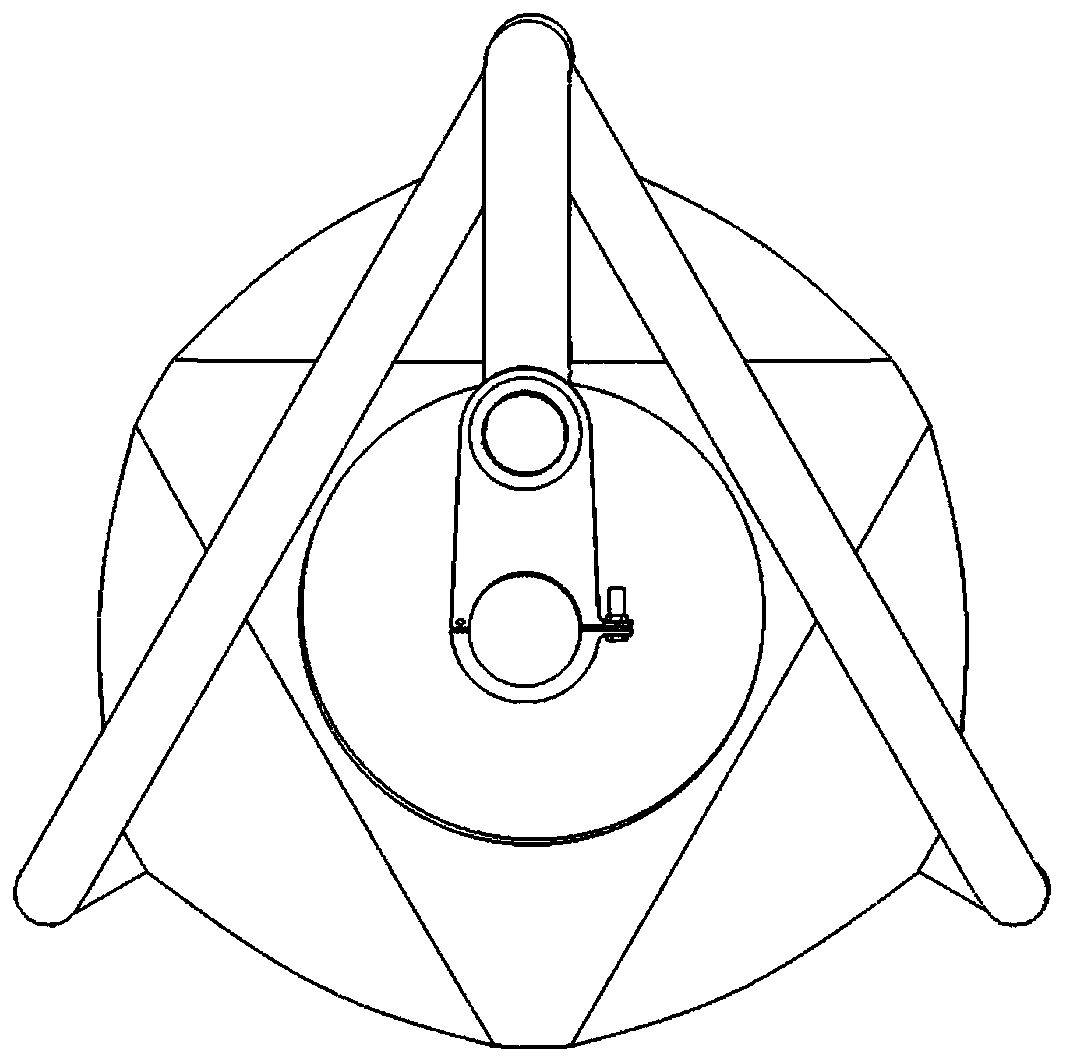

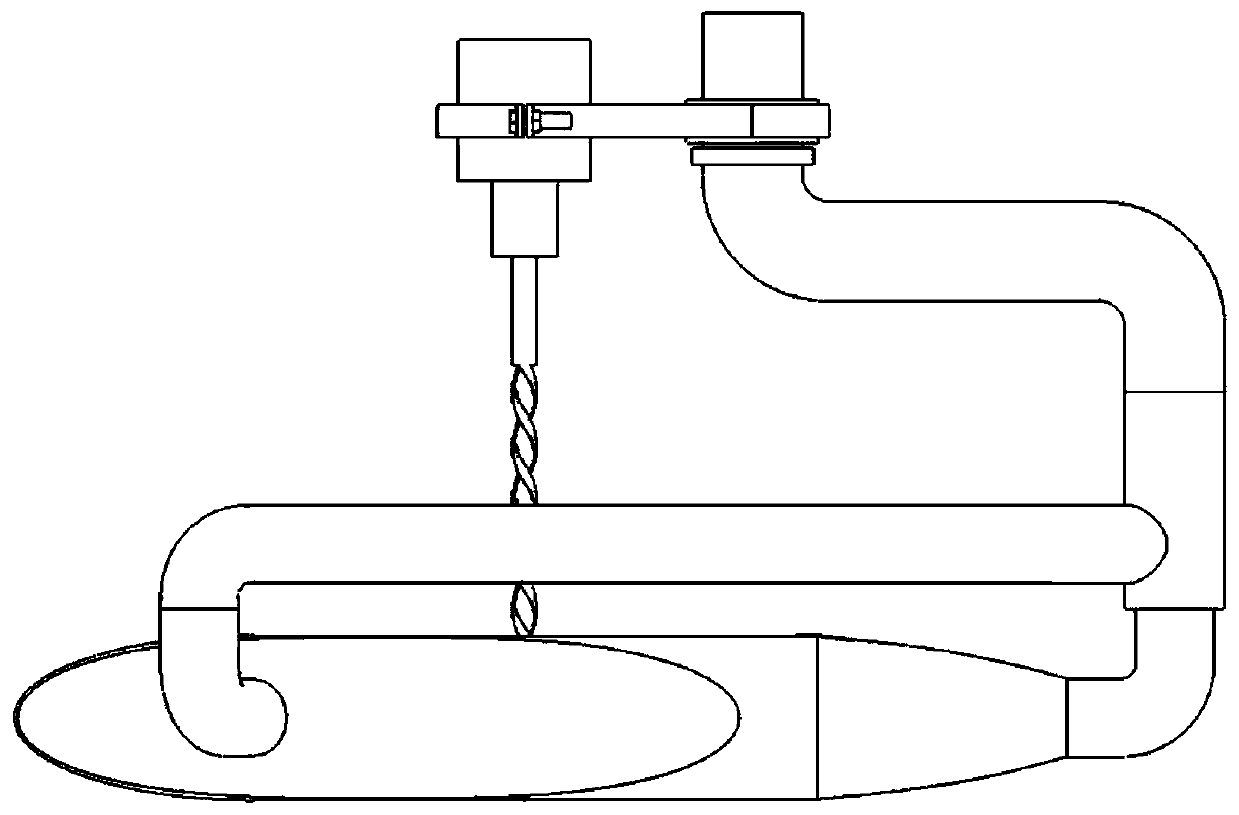

[0038] refer to Figure 1-11 In this embodiment, a device for recovering cuttings by air extraction is proposed, including the recovery port 1 of the cuttings collector, the wrapping 2 connected to the recovery port of the cuttings collector, the cuttings recovery pipe 3, and the total cuttings recovery pipe 4. Sliding collar 5, limit ring 6, cuttings collector fixing device 7, drill bit fixing cylinder 8, drill bit 9, fan 10, filter 11, chip collector 12, hose 13, hinge 14, fasteners 15. Four-way head 16, two or more elliptical tapered drill cuttings collector recovery ports surround the drill bit 360 degrees, use the airflow generated by the centrifugal fan to suck the drill cuttings into the recovery pipe, and then gather them to the main drill The chips are collected through the filter and settled into the chip collection box. When the drill bit starts to work, by adjusting the position of the limit ring, the recovery port of the chip collector and the tip of the drill bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com