Preparation device for surface flow pattern of wood-plastic composite material

A technology of wood-plastic composite materials and preparation devices, applied in the field of profile preparation, which can solve the problems of easy fading of film patterns, harmfulness to users, and shedding, etc., and achieve natural and smooth texture transition effects, diverse textures, and optimized structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

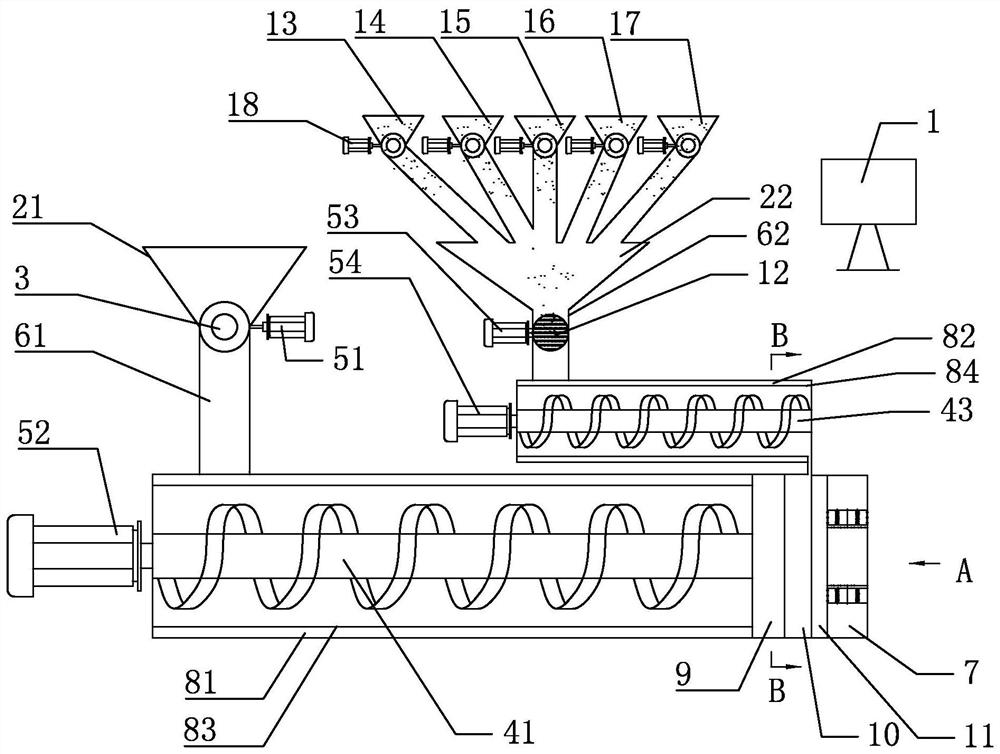

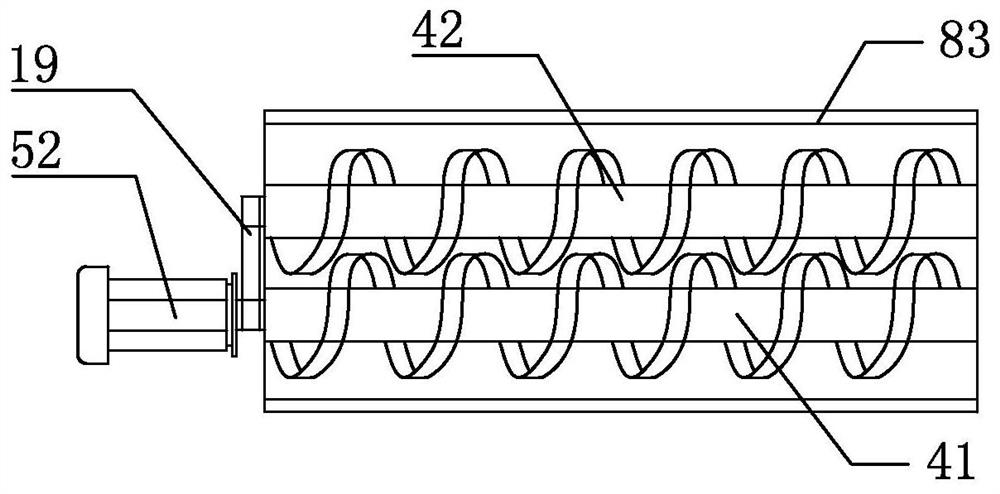

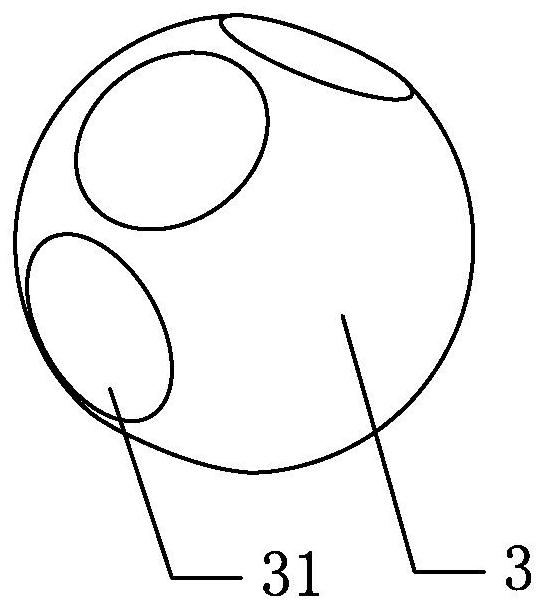

[0039] Such as figure 1As shown, a preparation device for surface flow patterns of wood-plastic composite materials includes an intelligent control system 1, a main material feeding mechanism, a main material melting and plasticizing mechanism, a color masterbatch mixing mechanism, a color masterbatch melting and plasticizing mechanism, Main material homogenizing mechanism 9, color masterbatch homogenizing mechanism 10, cooling mechanism 11, texture control mechanism 7, the output end of the main material feeding mechanism is connected to the main material melting and plasticizing mechanism, and the output end of the main material melting and plasticizing mechanism is connected to the main material The homogenizing mechanism 9, the output end of the color masterbatch mixing mechanism is connected to the color masterbatch melting and plasticizing mechanism, the output end of the color masterbatch melting and plasticizing mechanism is connected to the color masterbatch homogenizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com