High-temperature fatigue testing device under combined action of vanadium pentoxide corrosion and sulfuric acid corrosion

A vanadium pentoxide and fatigue testing technology, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as being in a high temperature environment and a corrosive environment for a long time, and unable to obtain data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

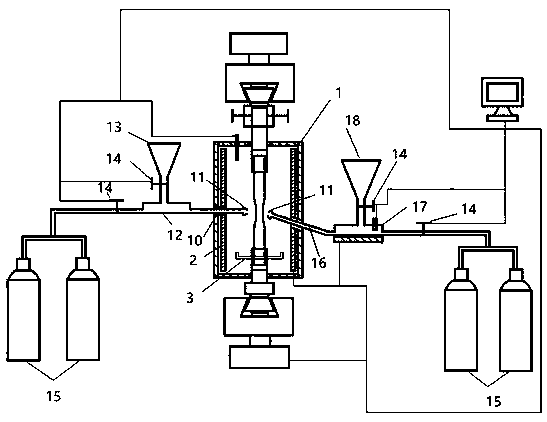

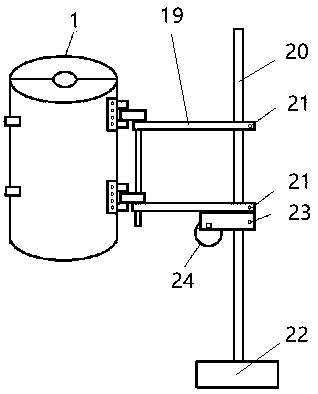

[0014] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 Shown: a kind of high-temperature fatigue test device that vanadium pentoxide corrosion and sulfuric acid corrosion act together, and it comprises heating cabin 1, and described heating cabin 1 is made up of mutually hinged two parts, on the top plate and the bottom plate of heating cabin 1 A via hole is provided, an electric heating device 2 is provided on the inner wall of the heating cabin 1, a tray 3 is provided at the bottom, and a temperature sensor is also provided in the heating cabin 1,

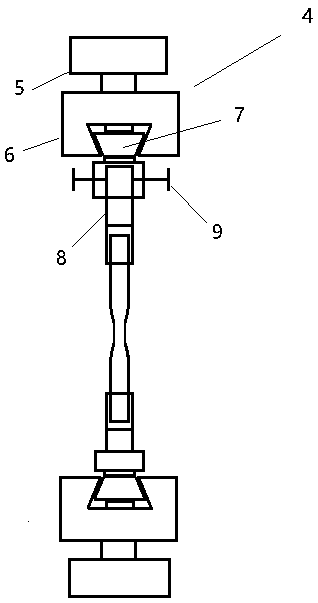

[0015] The test device also includes a sample clamping mechanism 4, the sample clamping mechanism 4 is composed of two longitudinally distributed clamping assemblies, the clamping assemblies include a hydraulic cylinder 5, the working of the hydraulic cylinder 5 A clamping jaw 6 is connected to the end, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com