Portable filling material in-situ performance monitoring simulation device and using method

A simulation device and a portable technology, applied in measuring devices, soil material testing, analyzing materials, etc., can solve problems such as real-time evaluation of stope structure safety, unfavorable adjustment of mining and charging strategies, etc., to reduce mutual influence, avoid errors, and reduce inaccurate The effect of the necessary loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] The invention provides a portable filling material in-situ performance monitoring simulation device and a using method.

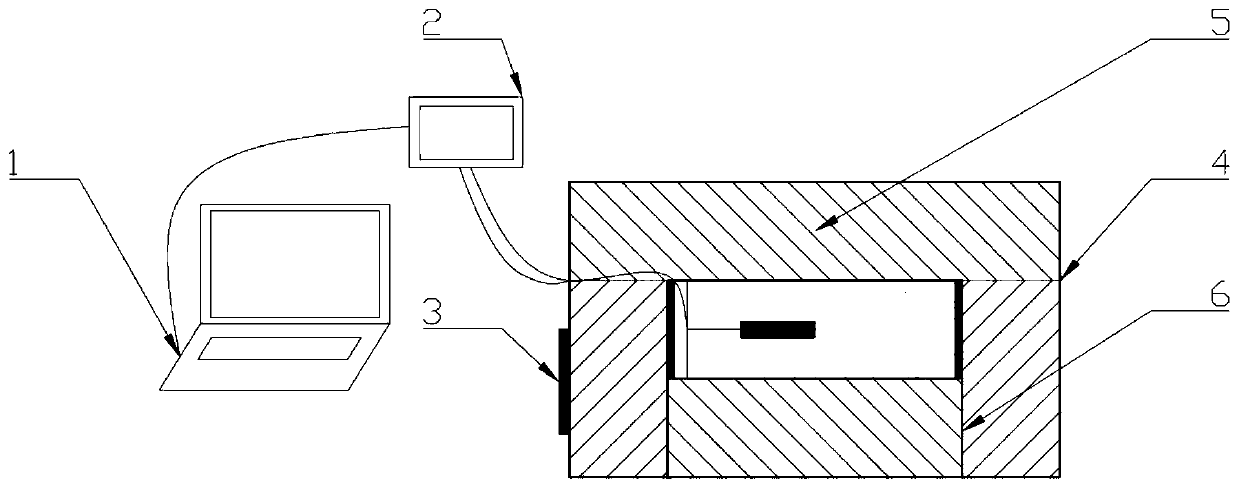

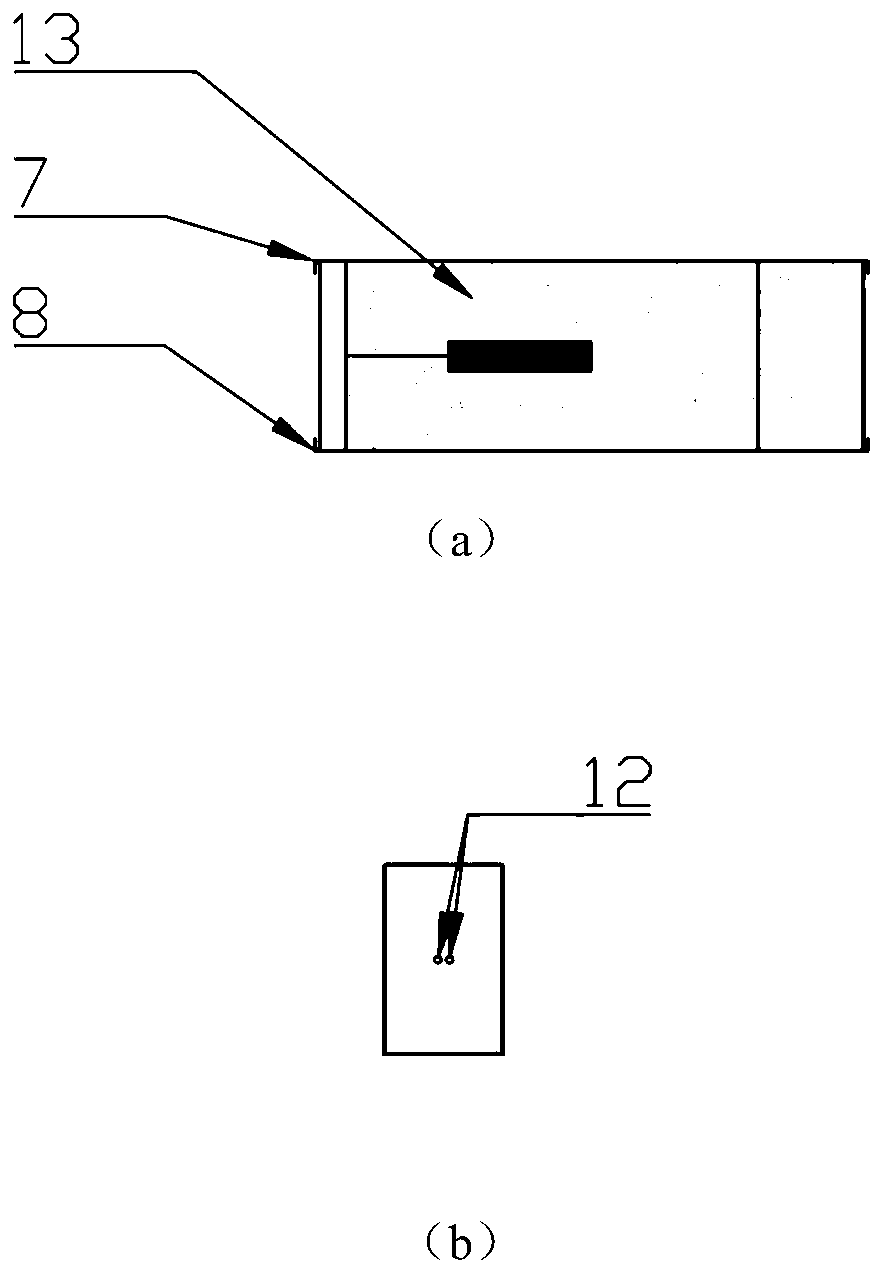

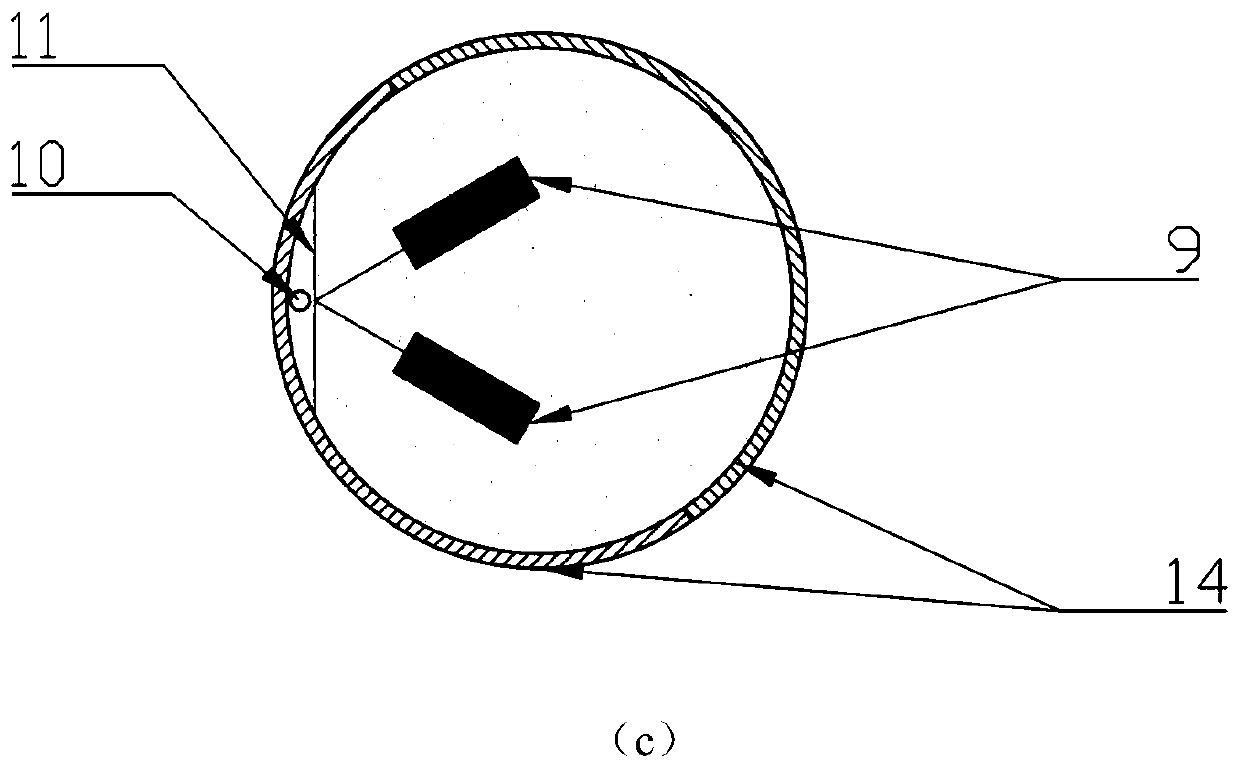

[0027] Such as figure 1 As shown, the device includes a computer 1, a data collector 2, a thermometer 3, a test chamber 4, a fixed cylindrical barrel 6 and a split material box 14, and the split material box 14 is located at the horizontal and vertical center positions of the test box 4, and the filling material 13 is full of split magazine 14, such as figure 2 As shown, an upper sealing cover 7 is arranged on the upper part of the split-type material box 14, and a lower sealing cover 8 is arranged on the lower part of the split-type material box 14. There is a sensor line hole 10 on the upper sealing cover 7, and the fixed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com