Anti-misoperation control system and method for switching process in chemical process

A technology of control system and control method, applied in general control system, control/adjustment system, program control, etc., can solve problems such as stop, whether the operation is in place, cannot be supervised, and cannot be actually controlled, so as to achieve the effect of safety control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

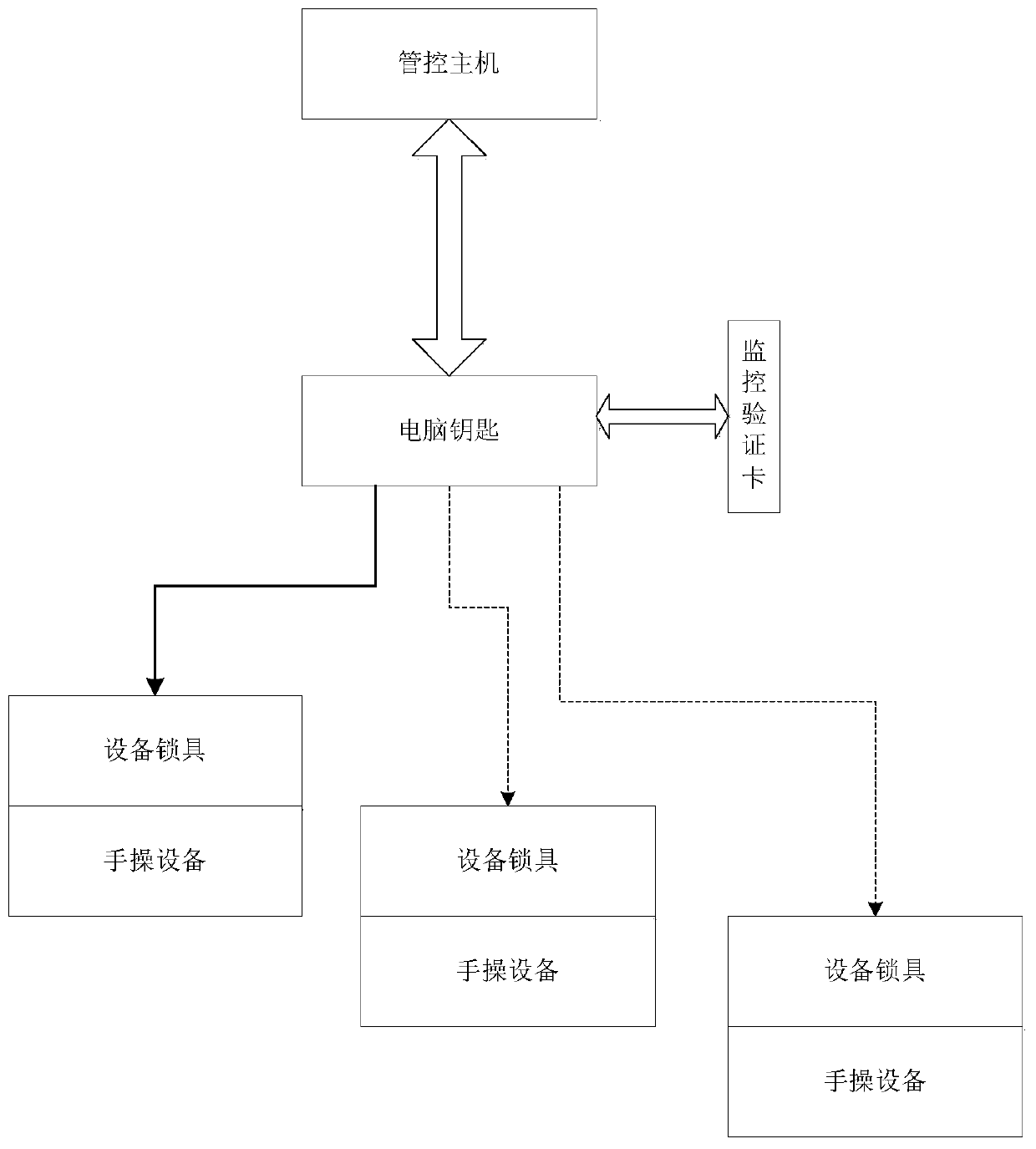

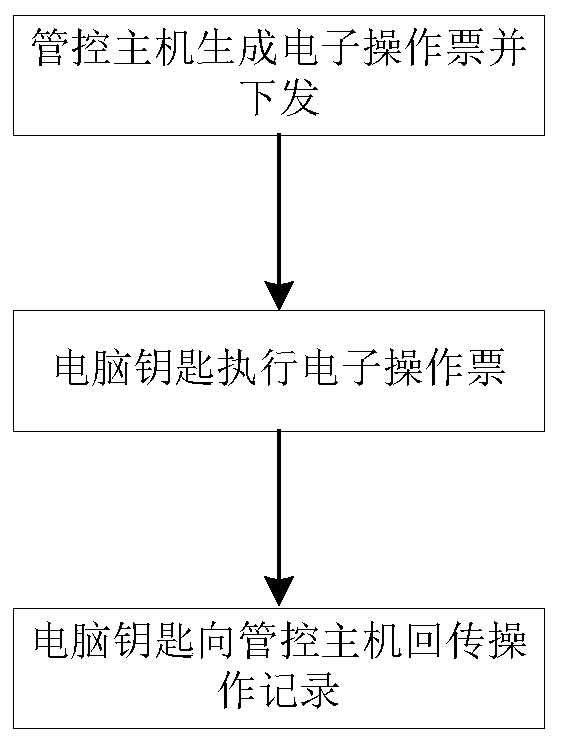

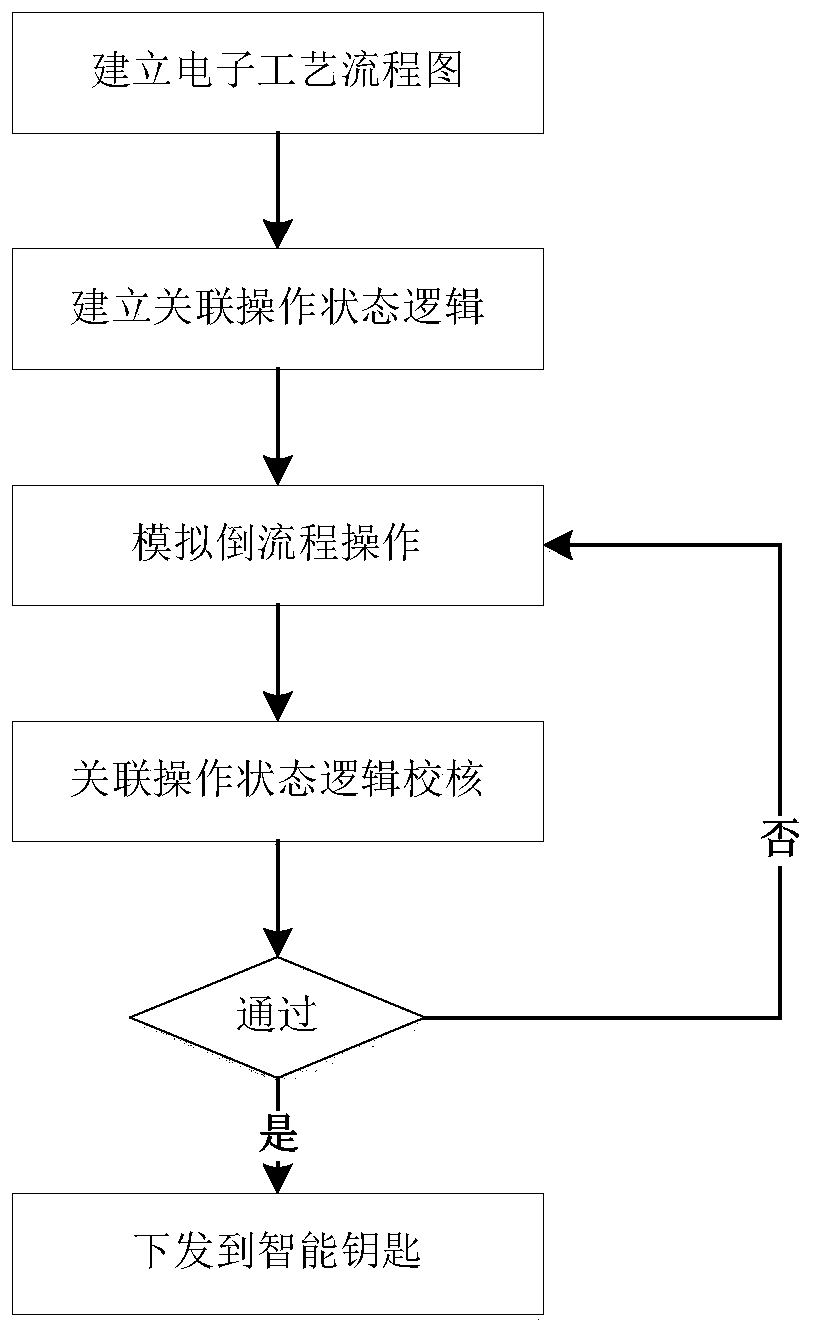

[0030] Such as figure 1 As shown, the anti-mistake control system for the manual operation point in the chemical process provided by this embodiment includes a control host, a smart key, a manual device, a device lock and a monitoring verification card. Among them, the management and control host is used as the upper computer, which is set in the control center; the manual equipment is set in the chemical process site, including the manual valve and or manual switch; the equipment lock is used for unlocking control of the manual valve and or manual switch. Readable identification, and the identification corresponds to the corresponding hand-operated equipment one by one. According to the risk level of the hand-operated equipment, the equipment locks are divided into two categories. The first category is locks with lock unlocking state detection, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com