Lithium ion power battery composite positive electrode material and preparation method thereof

A composite cathode material, power battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems affecting the structural stability, electrical conductivity and side reactions of high-voltage lithium manganate cathode materials, and achieve the realization of The effect of large-scale commercial application, improved uniformity, and ease of large-scale commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides a method for preparing a lithium-ion power battery composite positive electrode material described in the above technical solution, comprising the following steps:

[0024] providing a mixed solution including citric acid, lithium source, nickel source, manganese source and dopant source, adjusting the pH value, and then heating to obtain a sol-gel;

[0025] Drying and sintering the sol-gel in sequence to obtain doped modified lithium nickel manganese oxide;

[0026] The doped modified lithium nickel manganese oxide is pulverized, mixed with carbon black nanoparticles and carbon nanotubes, and dried to obtain the lithium ion power battery composite cathode material.

[0027] The invention provides a mixed solution including citric acid, lithium source, nickel source, manganese source and doping source, which is heated after adjusting the pH value to obtain sol-gel.

[0028] In the present invention, unless otherwise specified, the ra...

Embodiment 1

[0040] Weigh nickel acetate (8.9584g), manganese acetate (28.4304g) and aluminum nitrate (3.0012g) to prepare mixed solution A; weigh citric acid (17.6516g) and lithium hydroxide (3.5248g) to prepare mixed solution B. Solution B was slowly added dropwise to solution A to obtain mixed solution C, and the pH value was adjusted to 7.5 by adding ammonia water dropwise, and then the temperature was raised to 80°C for heating in a water bath while the magnetic stirrer continued to stir until a gel was formed. Then, the wet gel was dried at 110° C. for 24 hours to obtain a dry gel and pre-sintered at a temperature of 450° C. for 4 hours and a heating rate of 5° C. / min. Then, the calcined product is sintered to obtain the aluminum-modified lithium nickel manganate cathode material LiNi 0.45 mn 1.45 Al 0.1 o 4 , the sintering temperature is 800°C, the sintering time is 12h, and the heating rate is 5°C / min.

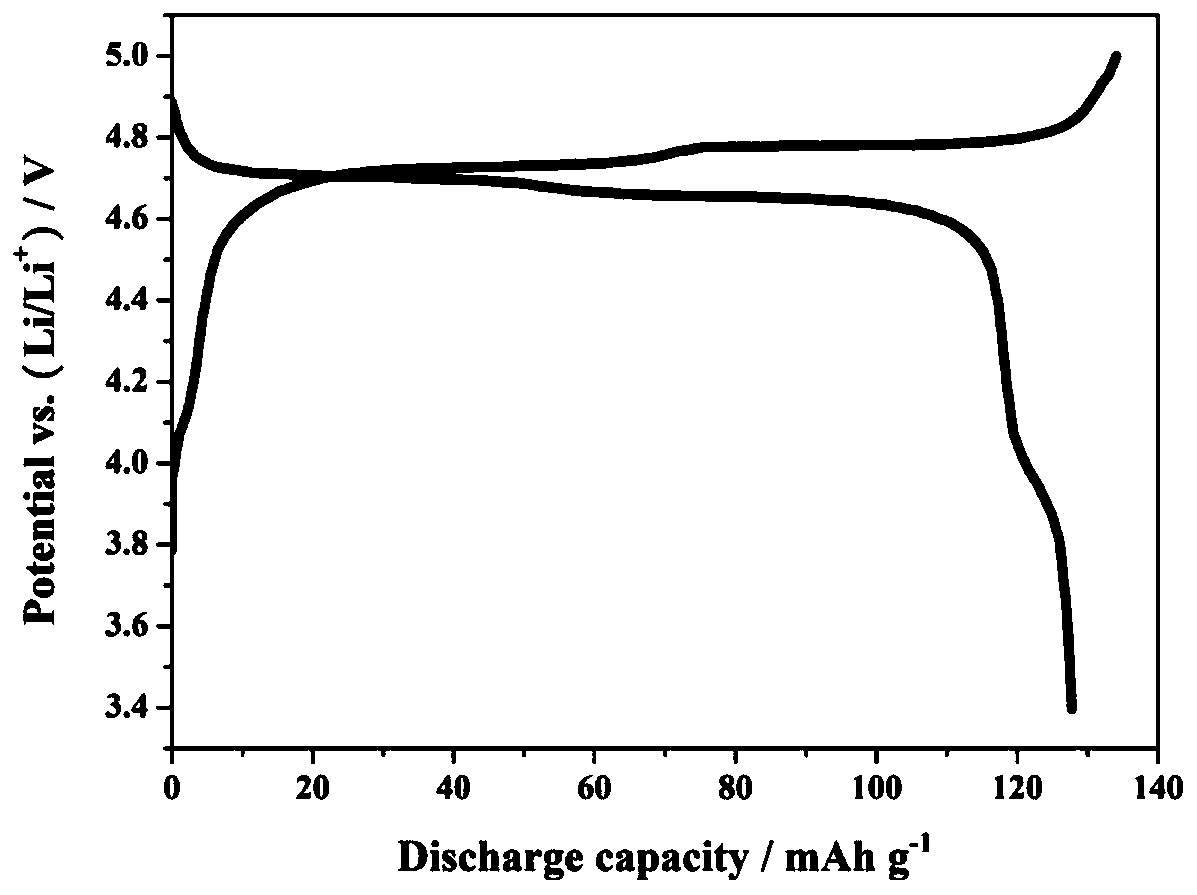

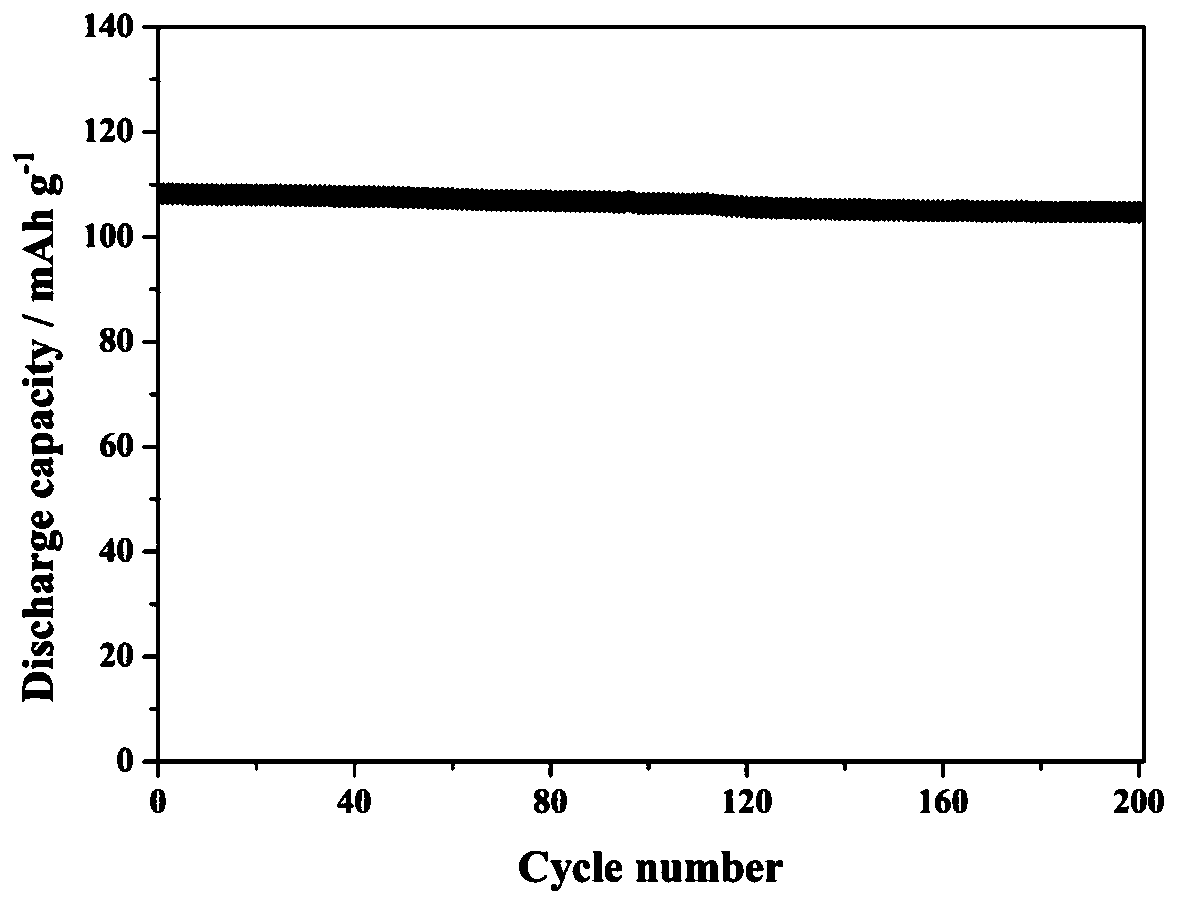

[0041] The LiNi prepared above was processed by ball milling 0.45 mn 1.4...

Embodiment 2

[0045] Weigh nickel acetate (8.9584g), manganese acetate (28.4304g), magnesium nitrate (1.0256g) and nano-titanium dioxide (0.3196g) to prepare mixed solution A; weigh citric acid (17.6516g) and lithium hydroxide (3.5248g ), prepare mixed solution B. Slowly add solution B to solution A dropwise to obtain mixed solution C, and adjust the pH value of mixed solution C to 7.5 by adding ammonia water dropwise, then raise the temperature to 80°C for heating in a water bath, while stirring continuously with a magnetic stirrer until a gel is formed. Then, the wet gel was dried at 105° C. for 30 hours to obtain a dry gel and pre-sintered at a temperature of 400° C. for 6 hours and a heating rate of 5° C. / min. Then, the calcined product is sintered to obtain the aluminum-modified lithium nickel manganate cathode material LiNi 0.45 Mg 0.05 mn 1.45 Ti 0.05 o 4 , the sintering temperature is 800°C, the sintering time is 12h, and the heating rate is 5°C / min.

[0046] The LiNi prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap