Semiconductor laser tube socket for PD die bonding

A technology of semiconductors and lasers, applied in the field of semiconductor laser tube sockets, can solve problems such as silver glue pollution and mismatching specifications, and achieve the effects of avoiding short circuits, increasing output rate, and improving equipment utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

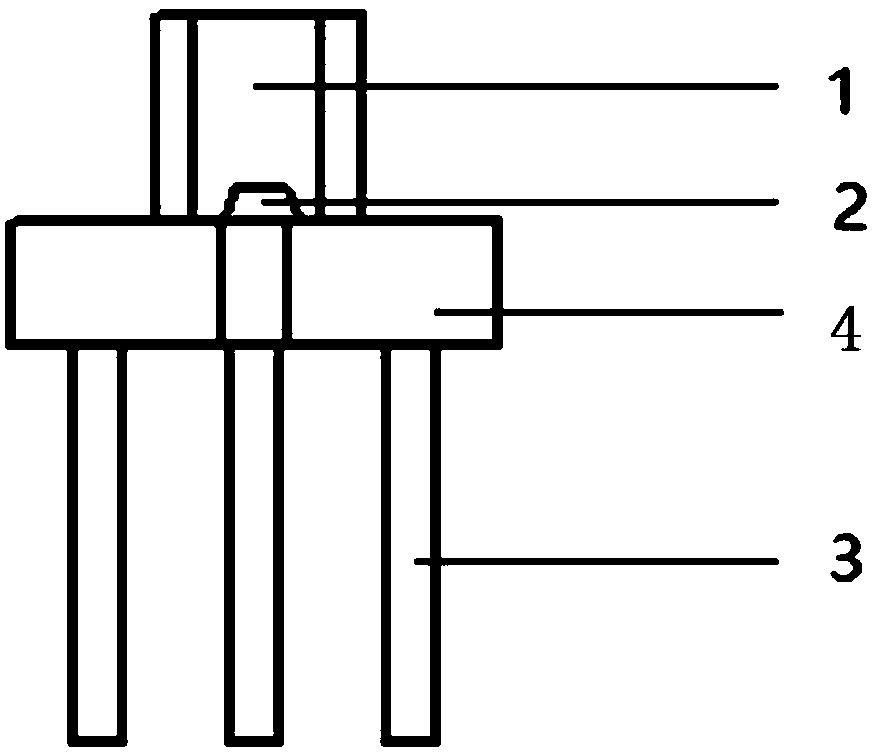

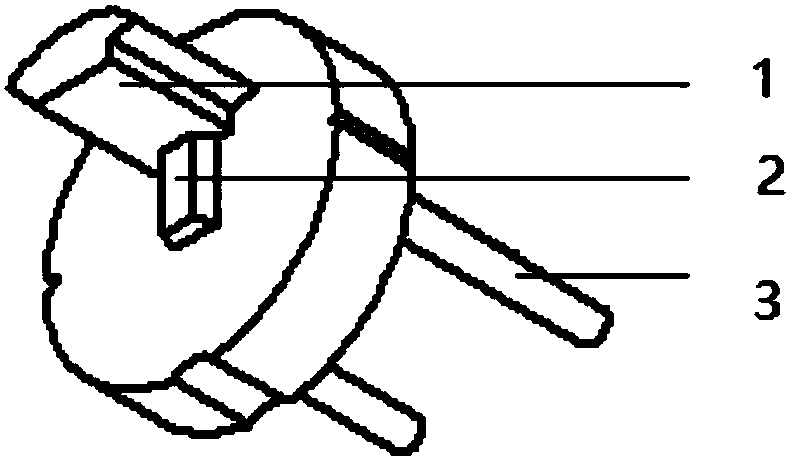

[0019] Such as Figure 1-2 shown.

[0020] A semiconductor laser socket for PD crystal bonding, comprising a main body and a tongue 1 arranged on the upper surface of the main body, a PD area 2 and a PIN pin 3 arranged on the lower surface of the main body; the tongue 1 and the PD area 2 Both are strip structures; the length direction of the tongue 1 is perpendicular to the upper surface of the main body 4, and the length direction of the PD area 2 is parallel to the upper surface of the main body 4; the left and right sides of the PD area 2 are slopes. surface structure. The setting of the slope structure makes the excessive silver glue flow down during the production process to avoid short circuit caused by the silver glue overflowing the PD.

Embodiment 2

[0022] As for the semiconductor laser stem for PD die bonding described in Embodiment 1, further, the length of the PD region 2 is 2200um, the width of the bottom is 700um, and the width of the top is 600um.

Embodiment 3

[0024] For the semiconductor laser tube base for PD die bonding described in Embodiment 1, further, one end of the PD region 2 is connected to the nozzle 1 . It can realize a relatively wide distribution selection range of PD positions, and can realize the selection of the maximum PD current to a characteristic value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

| Top width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com