A preparation method of composite decarburization liquid suitable for low-pressure and low-heat working conditions

A kind of working condition and composite technology, applied in separation method, chemical instrument and method, petroleum industry, etc., can solve the problems of high absorption pressure, large desorption heat consumption, adverse effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

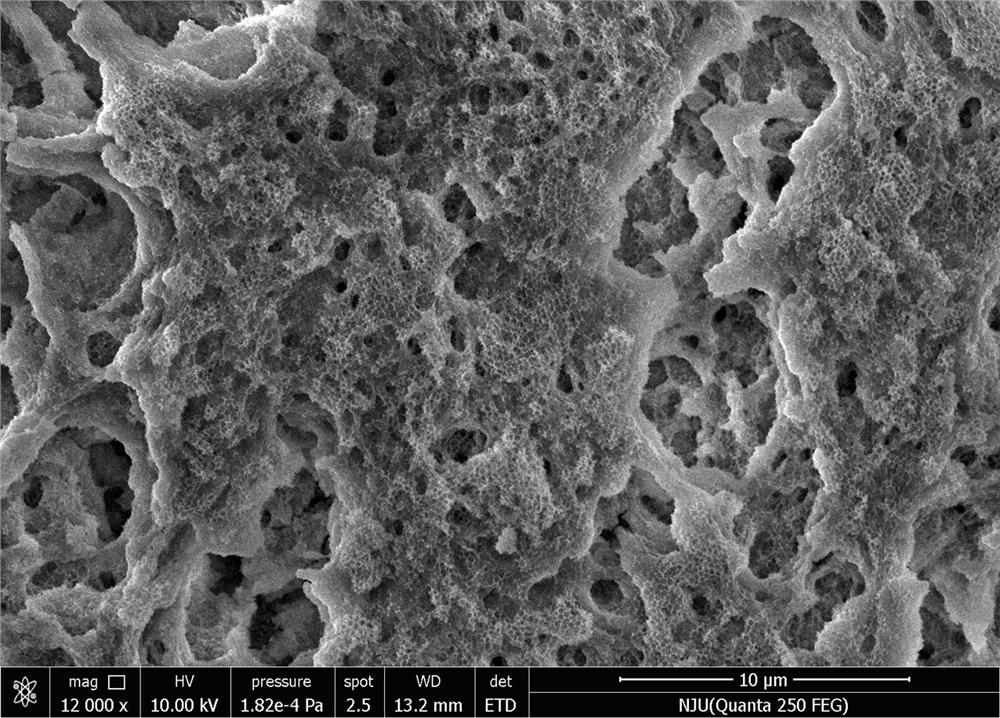

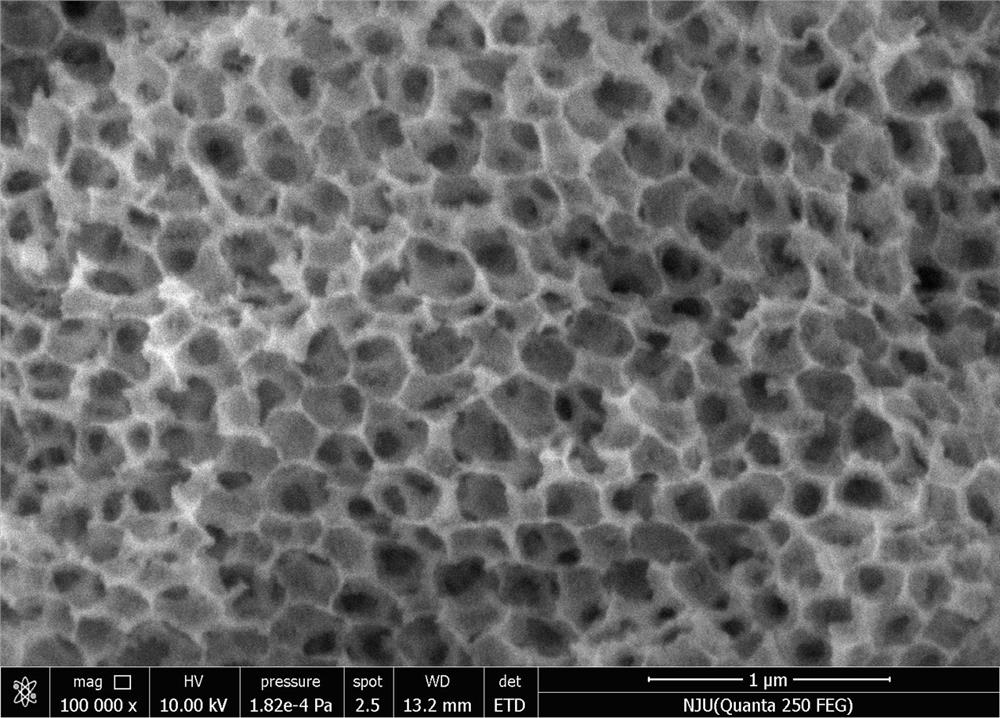

Image

Examples

Embodiment 1

[0020] A method for preparing a composite decarburization solution suitable for low-pressure and low-heat working conditions, comprising the following steps: (1) Add polymethacrylic acid with a diameter of 0.1 µm and a mass ratio of 10% to an aqueous ethanol solution with a mass ratio of 20% Methyl ester, add a 10% cerium nitrate aqueous solution by mass, then stir to dissolve and filter, dry the solid matter at 102°C for 4h, then heat up to 600°C in an air atmosphere and keep it for 5h, the heating rate is 0.5 ℃ / min to form roasted powder; (2) Dissolve chitosan powder in acetic acid aqueous solution and stir evenly with an electric stirrer to fully dissolve chitosan powder. Specifically, 5g chitosan powder is dissolved in In the acetic acid aqueous solution of 2%, be made into the chitosan solution of mass fraction 0.1%, then add the mixed solution that contains 1wt.% glutaraldehyde and 0.5wt.% sulfuric acid as cross-linking agent, obtain polymerization reaction raw material s...

Embodiment 2

[0022] A method for preparing a composite decarburization solution suitable for low-pressure and low-heat working conditions, comprising the following steps: (1) adding polymethacrylate with a diameter of 5 µm and a mass ratio of 50% to an aqueous ethanol solution with a mass ratio of 50% For ester, add zirconium nitrate aqueous solution with a mass ratio of 40%, then stir to dissolve and filter, dry the solid substance at 110°C for 6h, then heat up to 650°C in an air atmosphere and keep it for 4h, the heating rate is 5°C / min to form a roasted powder; (2) Dissolve chitosan powder in aqueous acetic acid solution, stir evenly to fully dissolve chitosan powder, make a chitosan solution with a mass fraction of 2%, and then add 1wt.% A mixed solution of glutaraldehyde and 0.5wt.% sulfuric acid is used as a crosslinking agent to obtain a polymerization reaction raw material solution; (3) soak the calcined powder obtained in step (1) into the polymerization reaction raw material solu...

Embodiment 3

[0024] A method for preparing a composite decarburization solution suitable for low-pressure and low-heat working conditions, comprising the following steps: (1) Adding polymethacrylate with a diameter of 2 µm and a mass ratio of 25% to an aqueous ethanol solution with a mass ratio of 30% For ester, add aluminum nitrate aqueous solution with a mass ratio of 22%, then stir to dissolve and filter, dry the solid substance at 150°C for 4h, then heat it up to 580°C in an air atmosphere and keep it for 6h to form a calcined powder; (2) Dissolve chitosan powder in acetic acid aqueous solution, stir evenly, make chitosan powder fully dissolve, make the chitosan solution of mass fraction 0.6%, then add containing 1wt.% glutaraldehyde and 0.5wt.% sulfuric acid The mixed solution is used as a cross-linking agent to obtain a polymerization reaction raw material solution; (3) soak the calcined powder obtained in step (1) into the polymerization reaction raw material solution obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com