Low-density and high-elasticity hydrophobic/oleophylic carbon sponge, preparation method and applications thereof

A technology of carbon sponge and high elasticity, which is applied in the field of functional material preparation, can solve problems such as limited application, and achieve the effects of easy operation, suitable for large-scale preparation, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

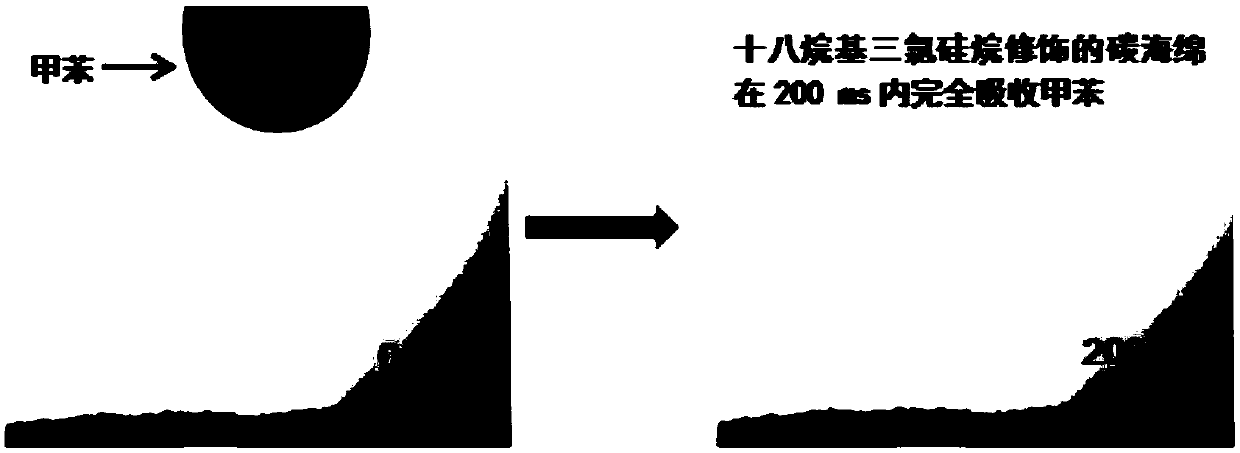

[0046]This embodiment provides a low-density and highly elastic hydrophobic / lipophilic carbon sponge (octadecyltrichlorosilane modified carbon sponge), which is prepared by a preparation method comprising the following steps:

[0047] 1) Wash the melamine sponge three times with deionized water and ethanol, and dry it in an oven at 80°C for 2 hours;

[0048] 2) The melamine sponge obtained in step 1) was calcined in an argon atmosphere at 800° C. for 2 h, and the heating rate was 5° C. / min to obtain a low-density and high-elastic carbon sponge (melamine-derived carbon sponge). The melamine-derived carbon sponge The density is 7.8mg / cm 3 , the extrusion deformation recovery is 96%, and then washed 3 times with deionized water and ethanol, and dried in an oven at 80°C for 2h;

[0049] 3) The melamine-derived carbon sponge obtained in step 2) was completely soaked in a toluene solution of 2 wt% octadecyltrichlorosilane for 30 minutes, and washed 5 times with toluene after taking...

Embodiment 2

[0054] This embodiment provides a low-density and highly elastic hydrophobic / lipophilic carbon sponge (hexadecyltrichlorosilane modified carbon sponge), which is prepared by a preparation method comprising the following steps:

[0055] 1) Wash the melamine sponge three times with deionized water and ethanol, and dry it in an oven at 80°C for 2 hours;

[0056] 2) The melamine sponge obtained in step 1) was calcined in an argon atmosphere at 800° C. for 2 h, and the heating rate was 5° C. / min to obtain a low-density and high-elastic carbon sponge (melamine-derived carbon sponge). The melamine-derived carbon sponge The density is 7.8mg / cm 3 , the extrusion deformation recovery is 96%, and then washed 3 times with deionized water and ethanol, and dried in an oven at 80°C for 2h;

[0057] 3) The melamine-derived carbon sponge obtained in step 2) was completely soaked in a toluene solution of 2 wt% hexadecyltrichlorosilane for 30 minutes, and washed 5 times with toluene after takin...

Embodiment 3

[0060] This embodiment provides a low-density and highly elastic hydrophobic / lipophilic carbon sponge (tetradecyltrichlorosilane modified carbon sponge), which is prepared by a preparation method comprising the following steps:

[0061] 1) Wash the melamine sponge three times with deionized water and ethanol, and dry it in an oven at 80°C for 2 hours;

[0062] 2) The melamine sponge obtained in step 1) was calcined in an argon atmosphere at 800° C. for 2 h, and the heating rate was 5° C. / min to obtain a low-density and high-elastic carbon sponge (melamine-derived carbon sponge). The melamine-derived carbon sponge The density is 7.8mg / cm 3 , the extrusion deformation recovery is 96%, and then washed 3 times with deionized water and ethanol, and dried in an oven at 80°C for 2h;

[0063] 3) The melamine-derived carbon sponge obtained in step 2) was completely soaked in a toluene solution of 2 wt% tetradecyltrichlorosilane for 30 min, and washed 5 times with toluene after taking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com