Elastic grinding tool and manufacturing method thereof

A technology of elastic abrasives and manufacturing methods, which is applied in the direction of manufacturing tools, abrasive materials, grinding devices, etc., can solve the problems of attenuation of sharpness of the grinding block surface, deterioration of heat dissipation capacity, and decline of grinding performance, etc., and achieves unmatched sharpness Decrease, improve wear resistance, reduce clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

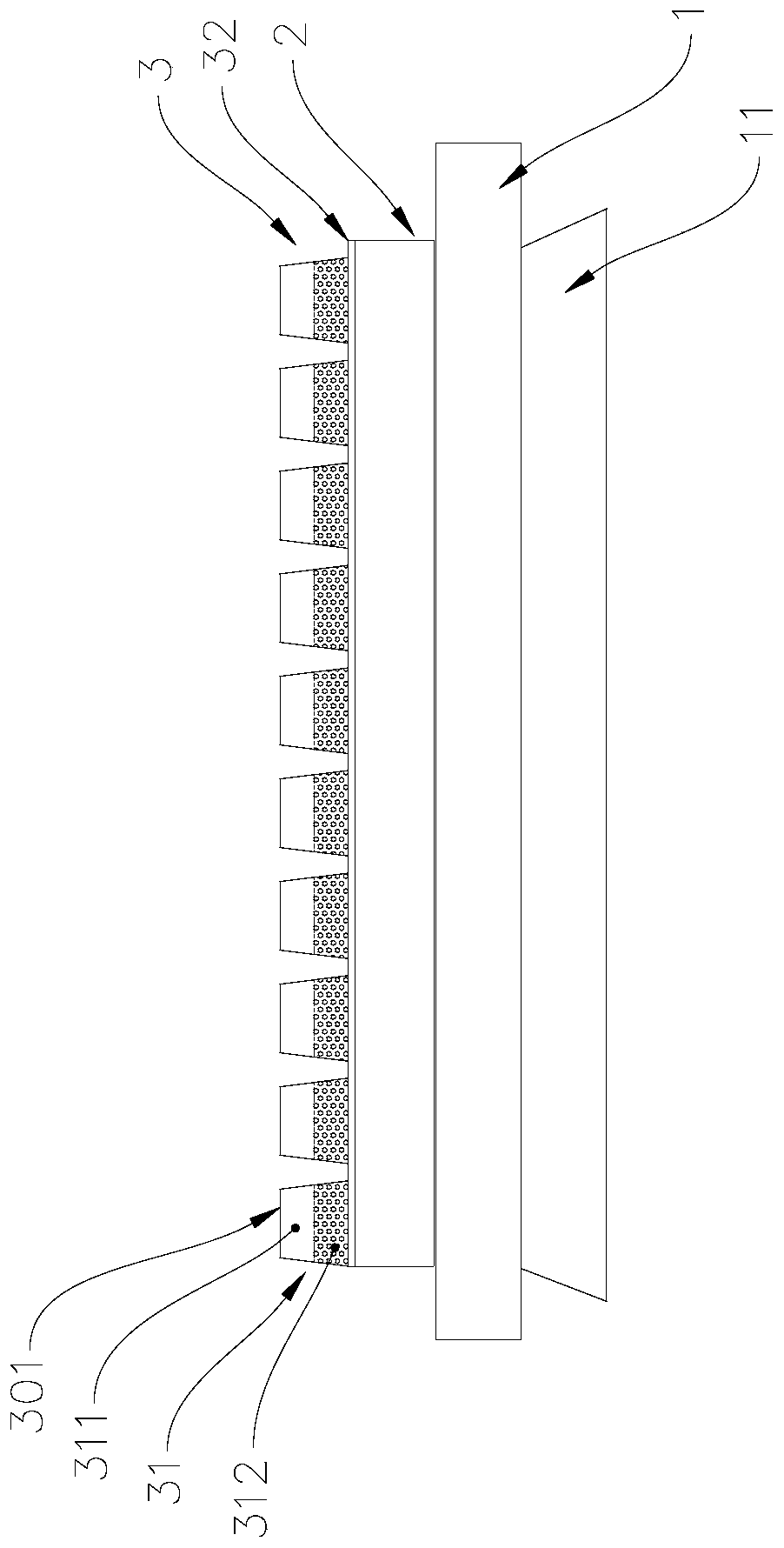

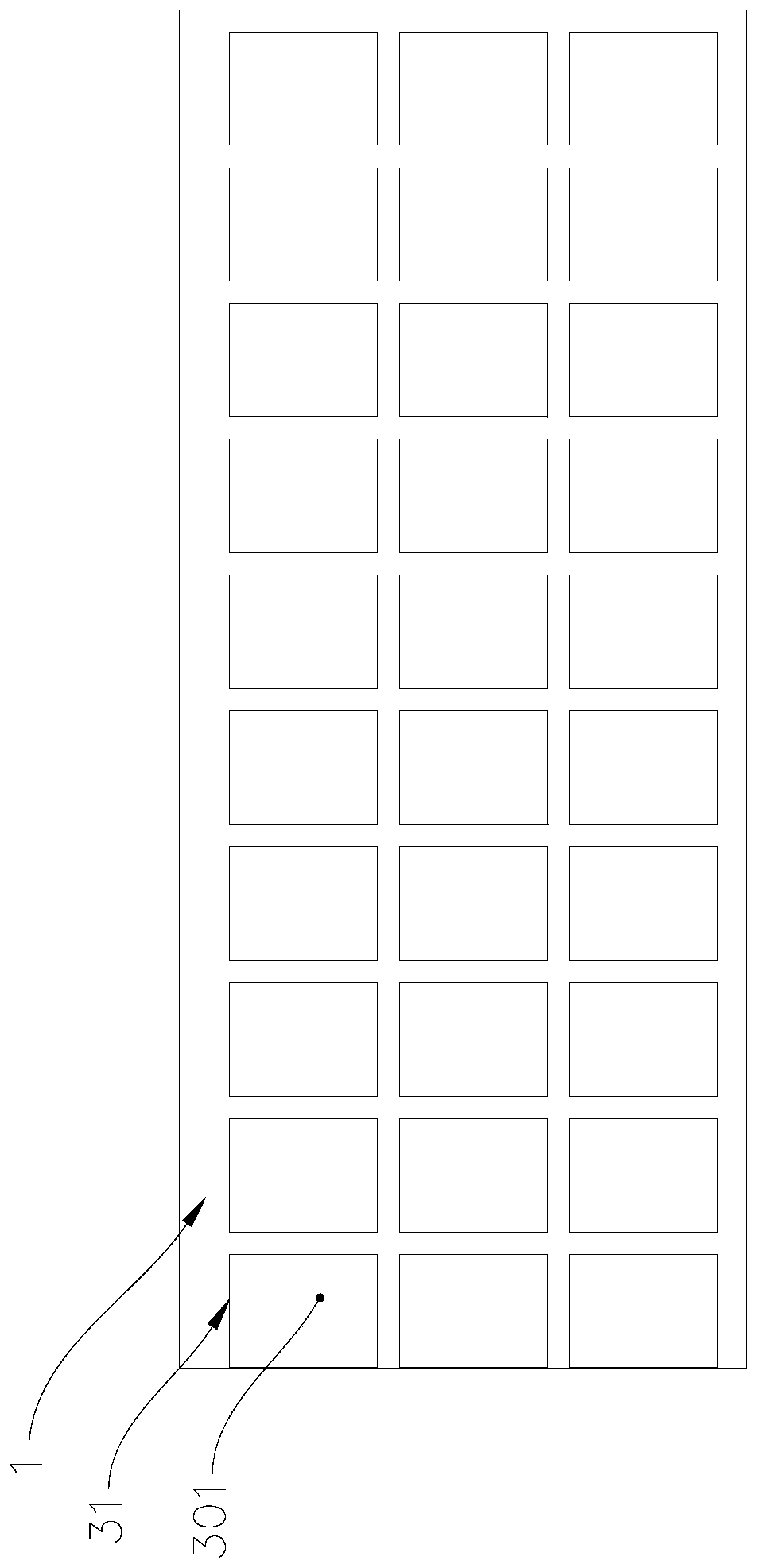

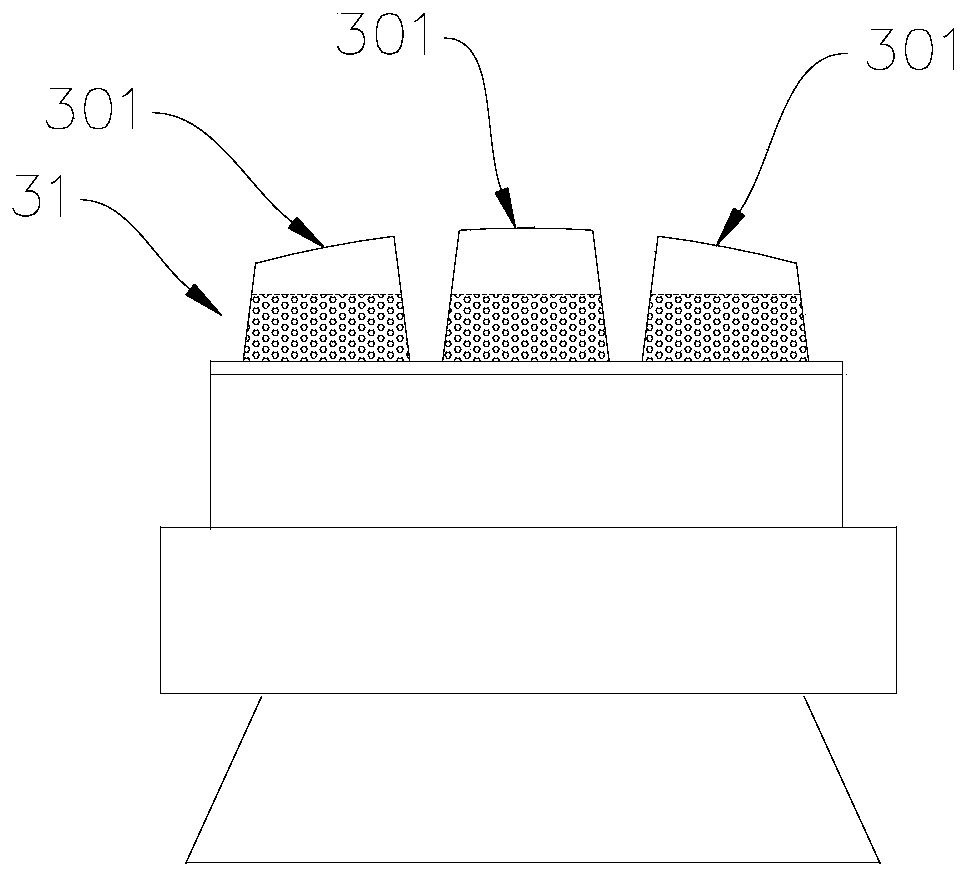

[0030] see Figure 1 to Figure 3 , Figure 1 to Figure 3 They are respectively the structural schematic diagrams of the first embodiment of the elastic abrasive tool of the present invention, the first viewing angle, the second viewing angle and the third viewing angle. The elastic grinding tool is composed of a base 1, an elastic layer 2 and a grinding layer 3 connected in sequence. The base 1 is made of plastic material. The base 1 has a dovetail-shaped engaging part 11 for clamping to the head of the grinding machine. The elastic layer 2 is fixedly bonded to the base 1 by glue.

[0031] The model layer 3 includes 30 grinding blocks 31 arranged in a rectangular array, the 30 grinding blocks 31 are divided into 3 columns, and each column includes 10 grinding blocks 31 . The grinding block 31 protrudes from the elastic layer 2, and in the protruding direction of the grinding block, the cross-sectional area of the grinding block gradually decreases from the extension start ...

no. 2 example

[0039] see Figure 5 , Figure 5 It is a structural schematic diagram of the second embodiment of the elastic abrasive tool of the present invention. In this embodiment, in the protruding direction of the grinding block 41 , the height of the rear part 412 is greater than that of the front part 411 ; the grinding surfaces 401 of the plurality of grinding blocks 41 are located on the same plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com