Combined proppant flow guiding capacity predicting method

A technology of conductivity and prediction method, applied in drilling composition, chemical instruments and methods, measurement, etc., can solve the problems of easily broken proppant, inability to provide high fracture conductivity, sand plugging, etc., to save The effect of human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

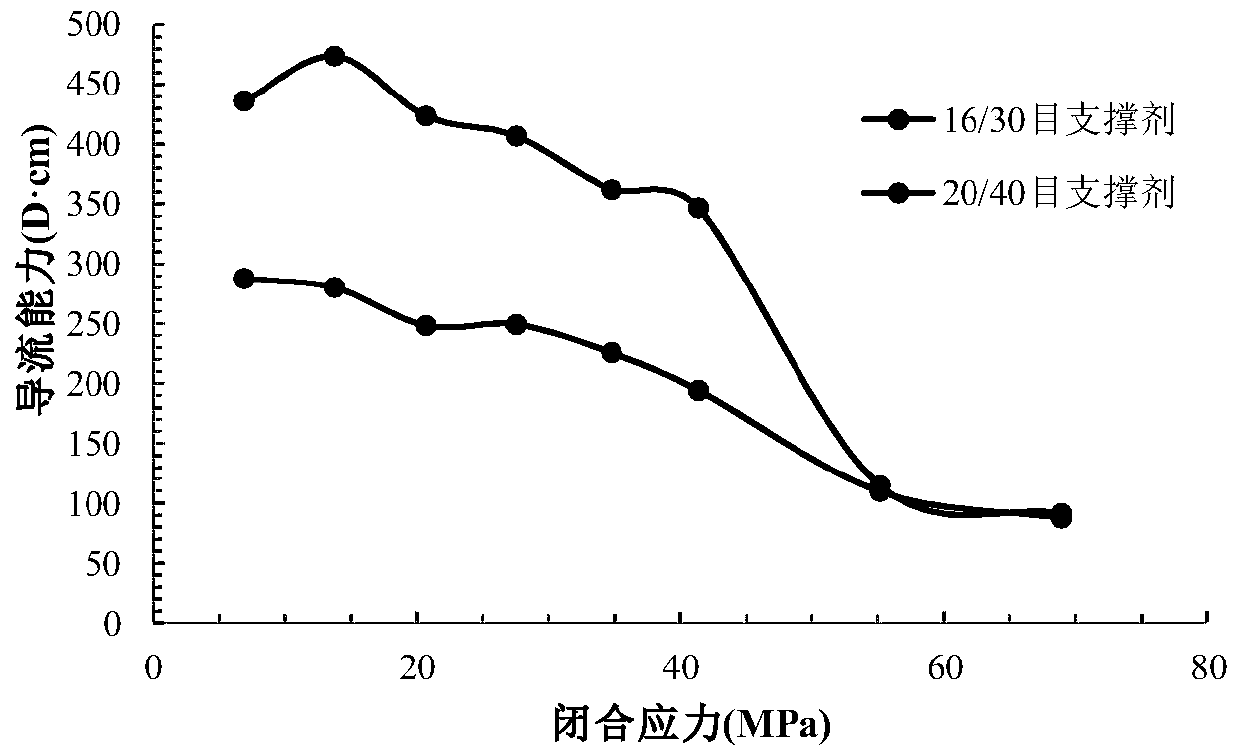

[0073] The combined proppant is composed of 16 / 30 mesh proppant 1 and 20 / 40 mesh proppant 2, and the flow conductivity of the proppant 1 and proppant 2 is as follows: figure 2 and as shown in Table 1:

[0074] Table 1 The conductivity of proppant 1 and proppant 2

[0075]

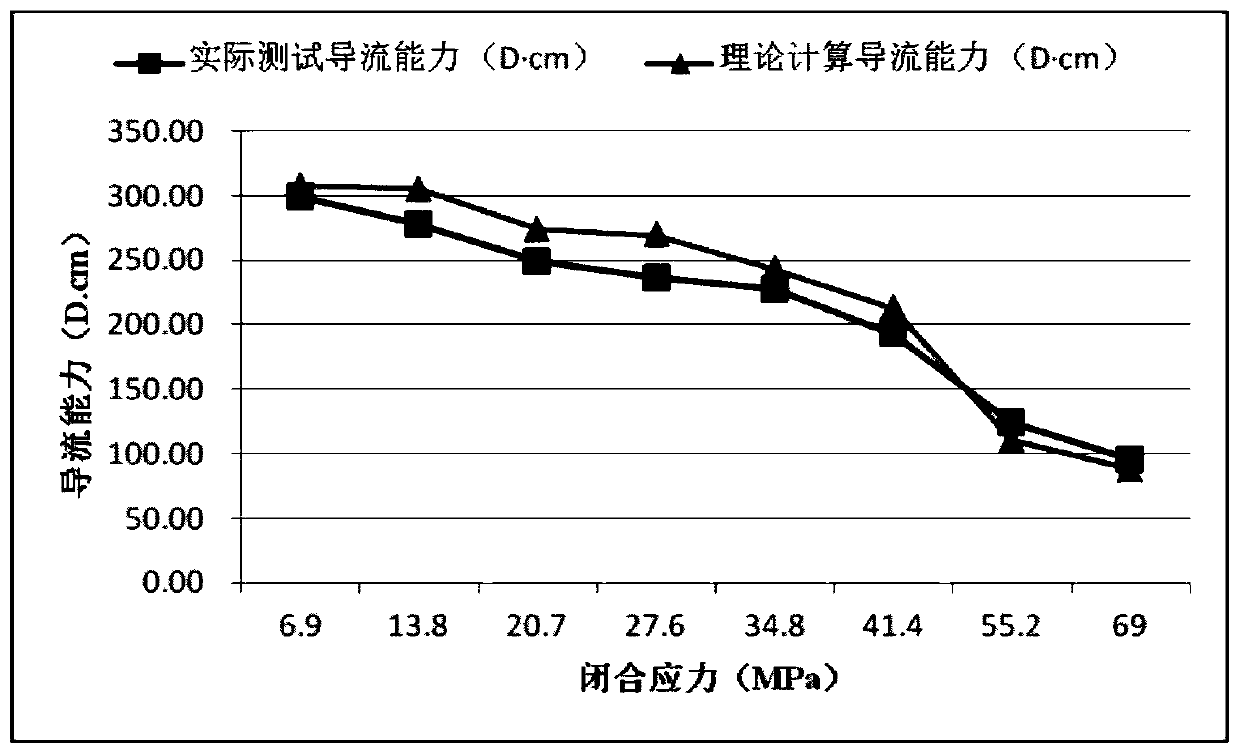

[0076] Calculate the conductivity values of 16 / 30 mesh proppant 1 and 20 / 40 mesh proppant 2 at different ratios according to formula (1), and compare them with the actual test conductivity values. The results are as follows Figure 3-6 and as shown in Table 2:

[0077] Table 2 Comparison of calculated and tested values of combined proppant conductivity under different proportions

[0078]

[0079]

[0080] As can be seen from the data in Table 2, the difference between the combined proppant conductivity calculated by the present invention and the actual test conductivity is very small, the largest being 20% 16 / 30 mesh proppant one and 80% 20 / 40 For the combination of proppant 2, the error...

Embodiment 2

[0082] It is known that the optimal conductivity of propped fractures in Well W1 is 4.48D cm, and the fractures in Well W1 are supported by a combination of proppants. The optimal conductivity is based on the optimal productivity of Well W1, and numerical simulation From software simulation, the combined proppant is composed of 30 / 50 mesh proppant 1 and 40 / 70 mesh proppant 2, 3kg / m 2 Proppant 1 has a conductivity of 5.17D·cm, 5kg / m under the condition of closure stress of 46.5MPa 2 The conductivity of proppant 2 under the condition of closure stress of 46.5MPa is 4.42D cm, and the ratio of proppant 1 to proppant 2 is 9:91 calculated according to formula (7) and formula (8).

[0083] According to the well logging data, there are secondary fractures in Well W1, and the fractures are supported by powder pottery, and the proportion of the proppant in the powder pottery can be determined according to the ratio of secondary fractures to primary fractures. The formula for calculatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com