Torque control method and device for Miller cycle engine

An engine torque, Miller cycle technology, applied in engine control, automatic control, automatic control and other directions, can solve problems such as poor dynamic characteristics, single control parameters, and can not meet the design requirements of hybrid vehicle controllers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

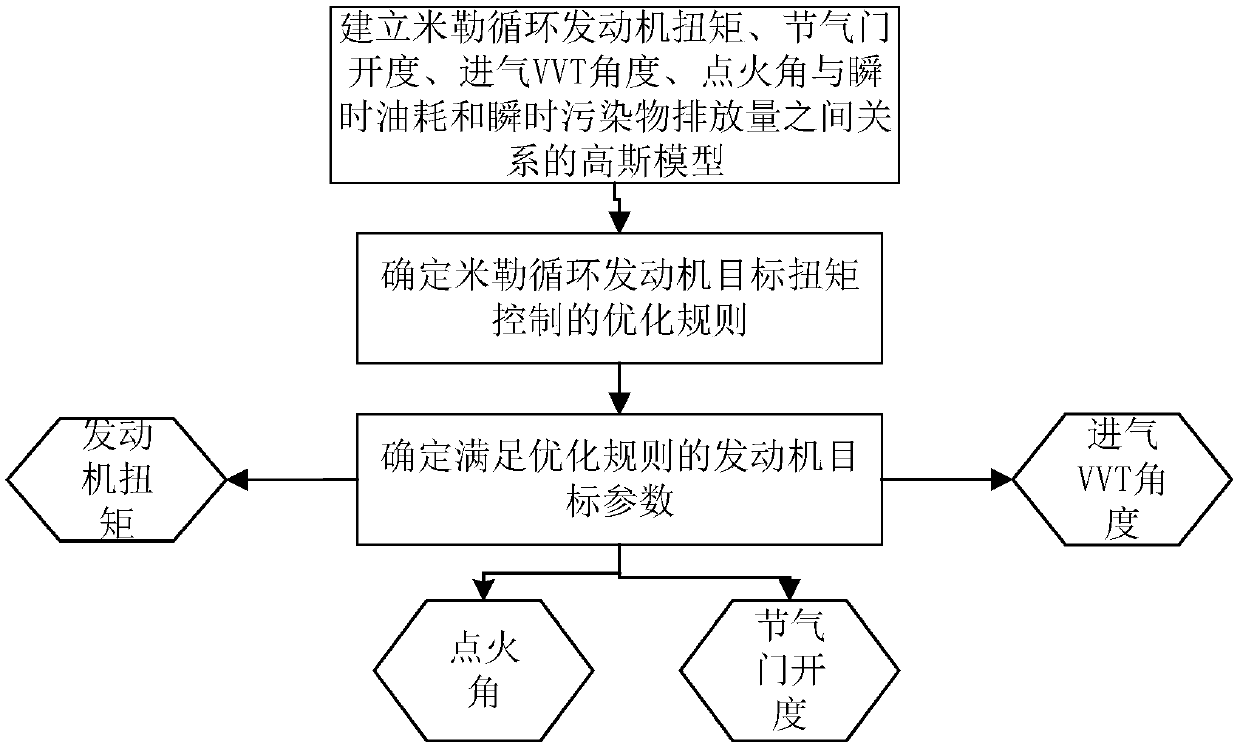

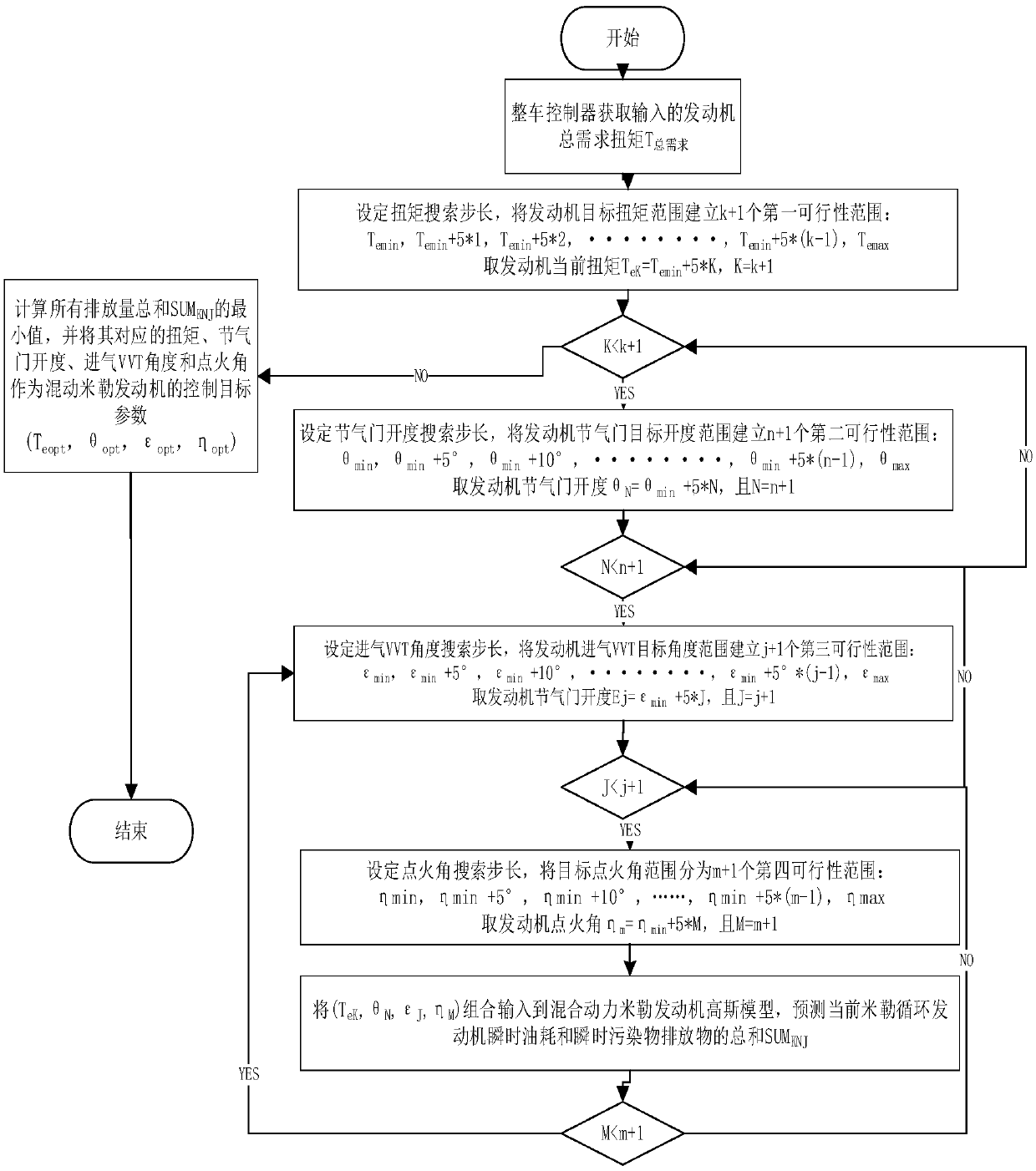

[0041] like figure 1As shown, the Miller cycle engine torque control device provided by the present invention includes modeling software and a vehicle controller connected with the modeling software signal, a torque sensor, a throttle opening sensor, an intake VVT angle sensor, an engine speed sensor , ignition angle sensor, fuel consumption sensor and pollutant emission sensor. The present invention utilizes torque sensor, throttle opening sensor, intake VVT angle sensor, engine speed sensor, ignition angle sensor, fuel consumption sensor and pollutant emission sensor, and different engine speeds and loads collected from equipment such as engine test bench Get the engine torque information,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com