Scroll plate measuring method and device based on numerical control motion platform

A motion platform and measurement device technology, applied in the field of precision measurement, can solve the problems of low detection efficiency, measurement interference, cumbersome process, etc., and achieve the effects of strong anti-interference ability, easy implementation, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

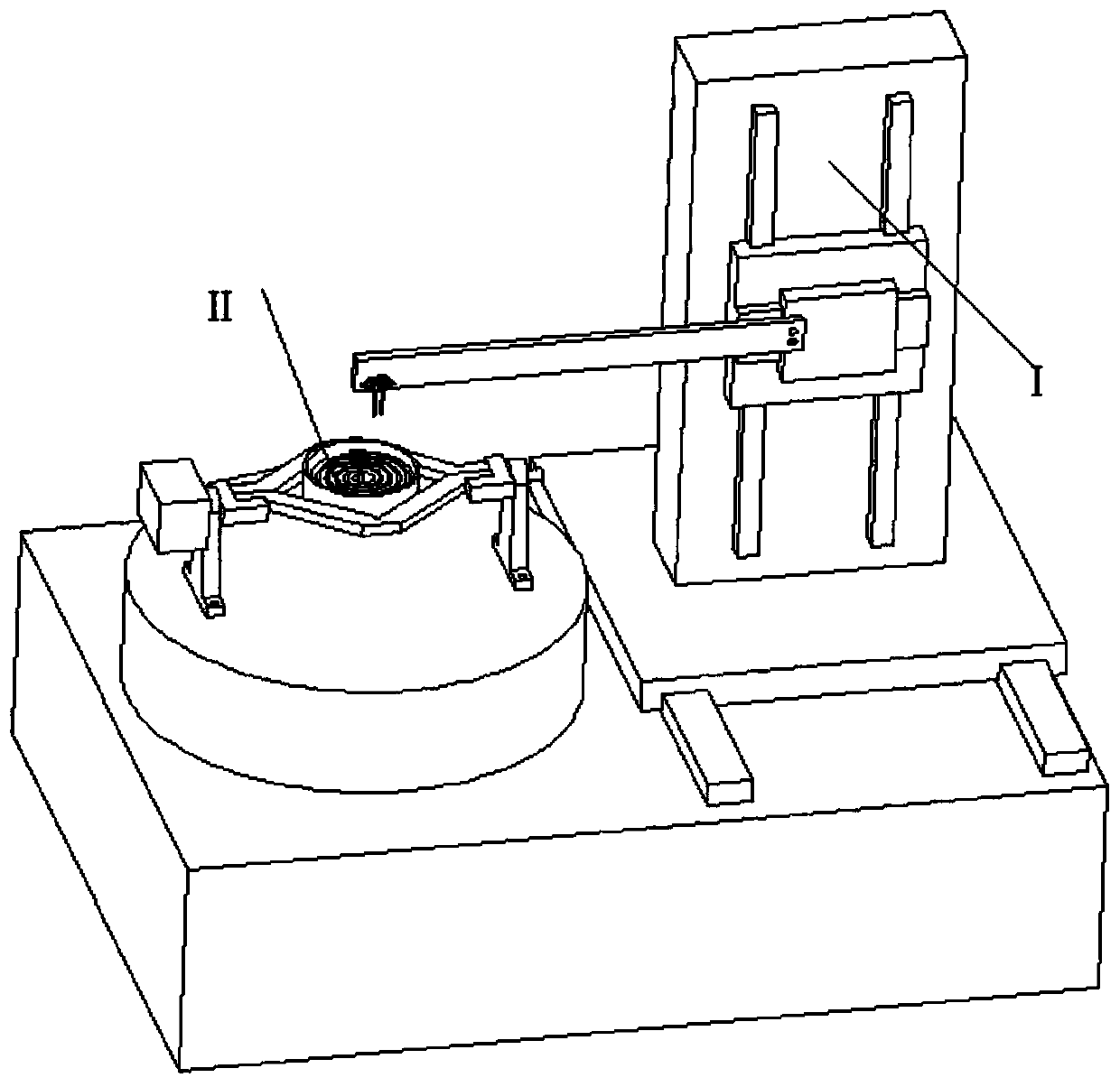

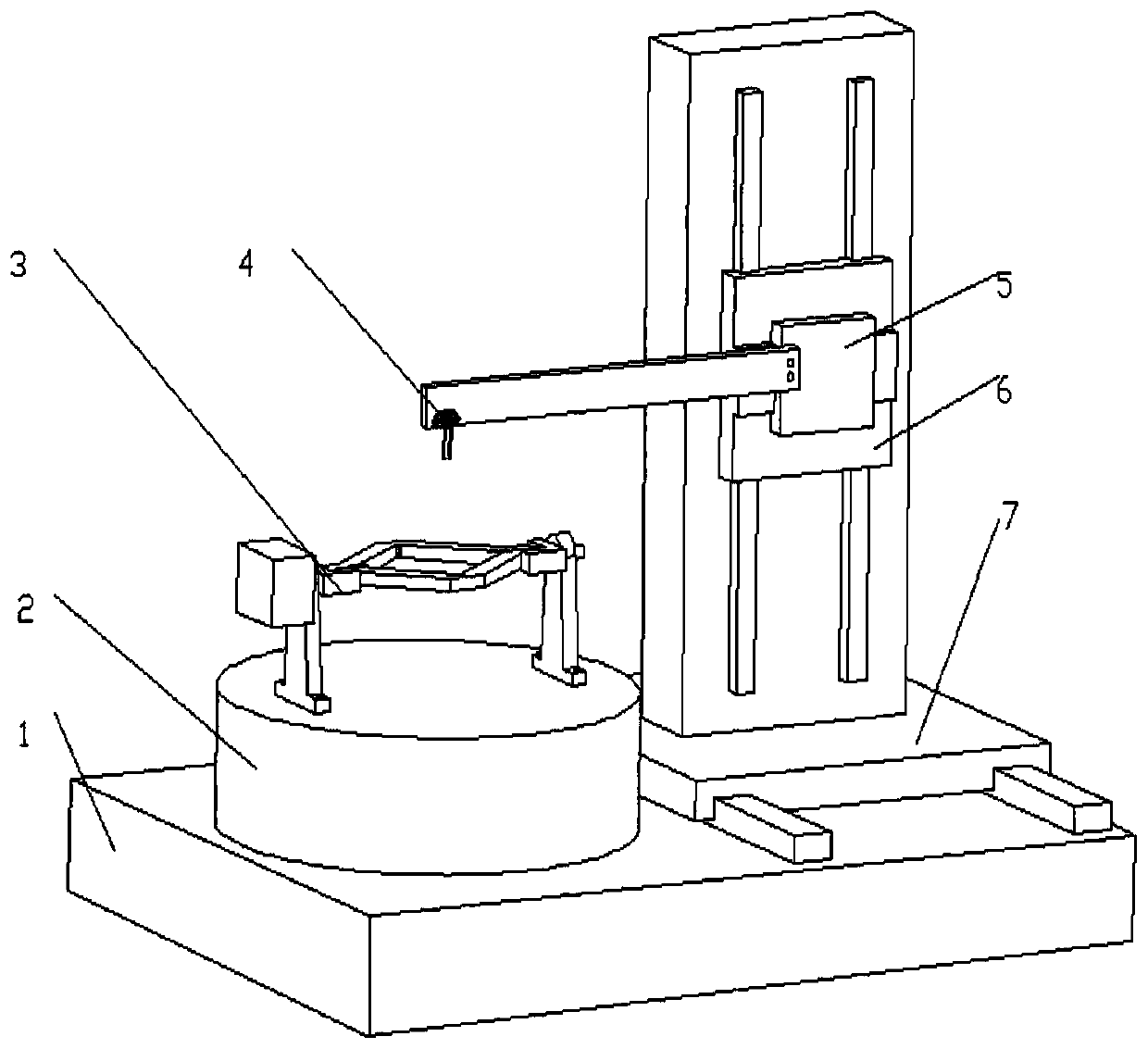

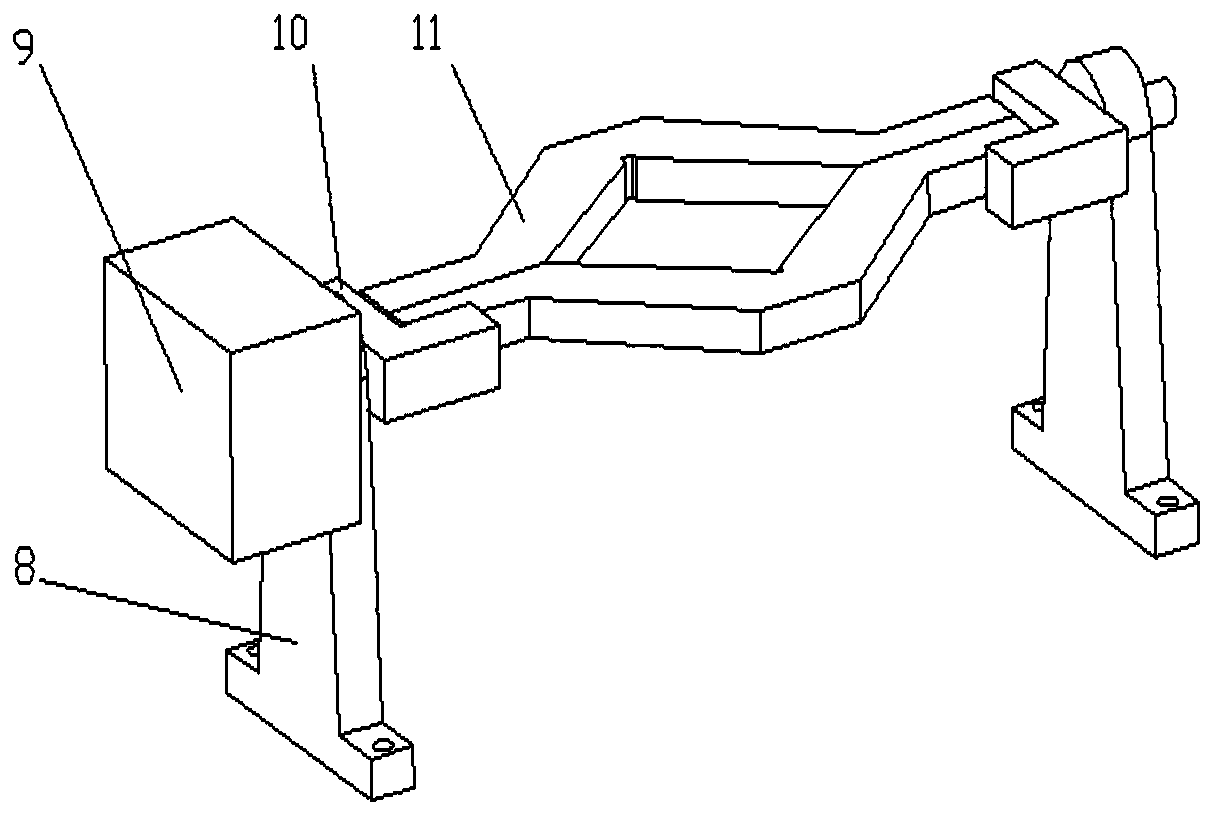

[0048] Such as figure 1 and figure 2 As shown, the scroll measuring device based on the numerical control motion platform provided by the present invention, the scroll measuring device I based on the numerical control motion platform consists of a base 1, a rotating spindle part 2, an overturning clamping part 3, and a two-pole grating scanning double ball measuring device. It consists of head part 4, radial axis movement mechanism 5, vertical axis movement mechanism 6, tangential axis movement mechanism 7, computer, software, data acquisition card, and motion control card. Among them, the rotary spindle part 2 adopts a high-precision dense ball bearing structure, with high axial and radial runout accuracy, and is driven by a servo motor to drive a positioner such as a photoelectric encoder disk; the radial axis movement mechanism 5, the vertical axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com