Line patrol robot troubleshooting and self-checking data acquisition method

A line inspection robot and troubleshooting technology, applied in the direction of instruments, overhead lines/cable equipment, measuring devices, etc., can solve problems such as inability to perform inspections, difficult work tasks, and high safety risks of manual wiring, and achieve timely maintenance The effect of maintaining line inspection robots, handling emergencies in a timely manner, and avoiding large-scale rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

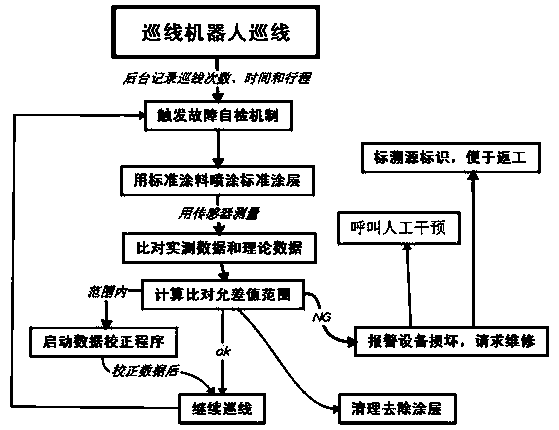

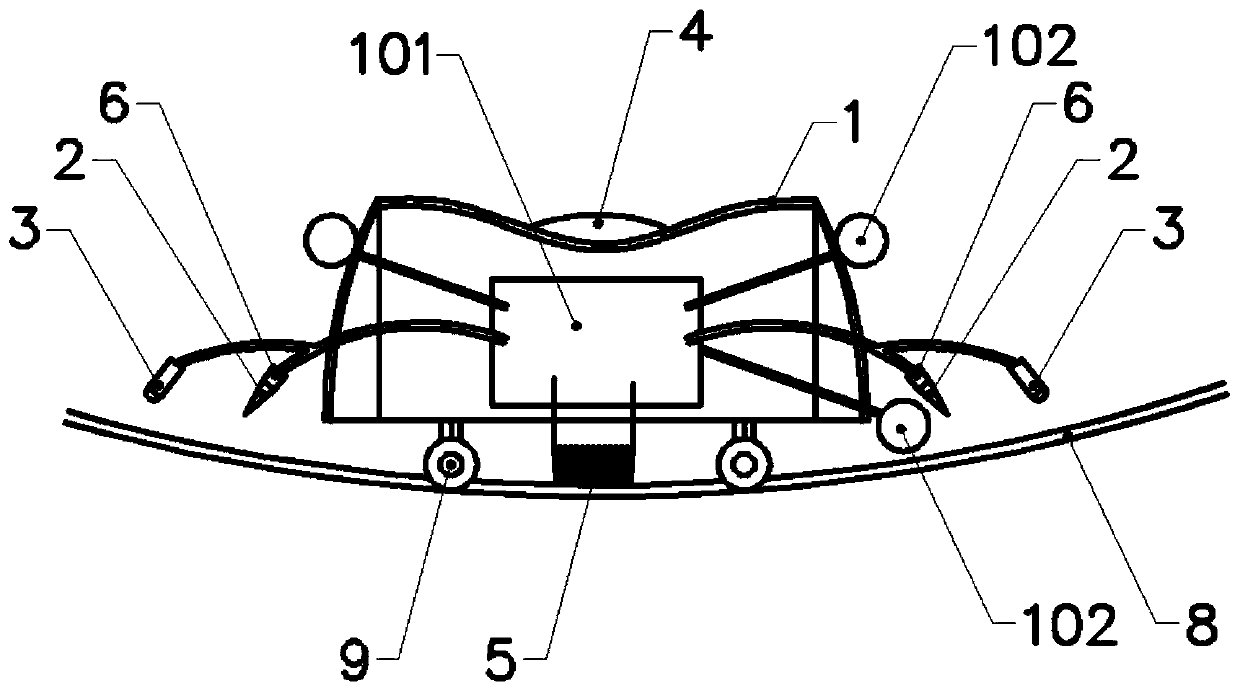

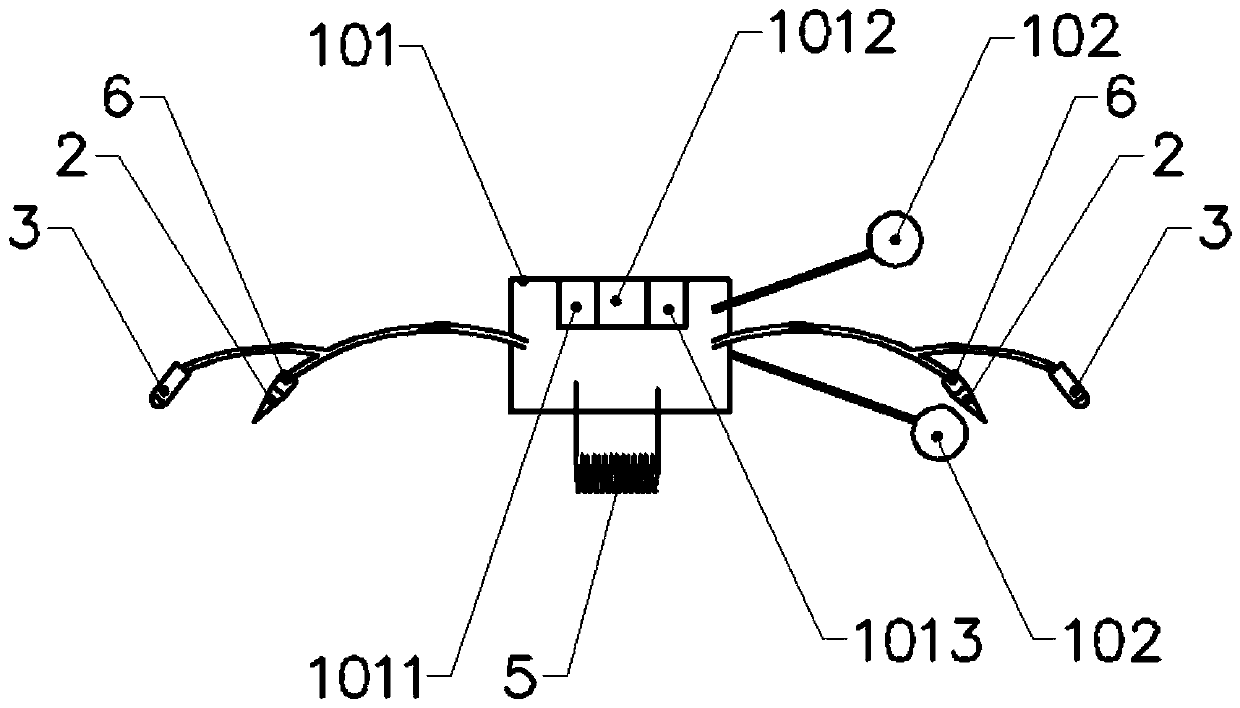

[0053] The maintenance personnel place the line inspection robot of the present invention in the section of the transmission line that needs to be detected, so that the line inspection robot enters the line inspection mode, and various conventional detection sensors that come with the line inspection robot detect, measure, and record the real-time data of the current transmission line At the same time, it also starts the troubleshooting and self-inspection data acquisition software, and records the accumulated working time, the length of the detection stroke, and the number of times of the cumulative switch on and off while working. When the data reaches the preset standard value, it will automatically trigger the troubleshooting and self-test Self-inspection mode once, the main control circuit board controls the motor, drives the paint pump, draws quick-drying paint from the paint storage tank, aligns it with the power line, sprays it from the nozzle, controls the shape through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com