Novel high-reliability slewing bearing service life evaluation method

A technology for slewing bearing and life evaluation, which is applied in the testing of mechanical components, the identification of patterns in signals, and the testing of machine/structural components. Sample size, improved accuracy, and the effect of accurate life prediction models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

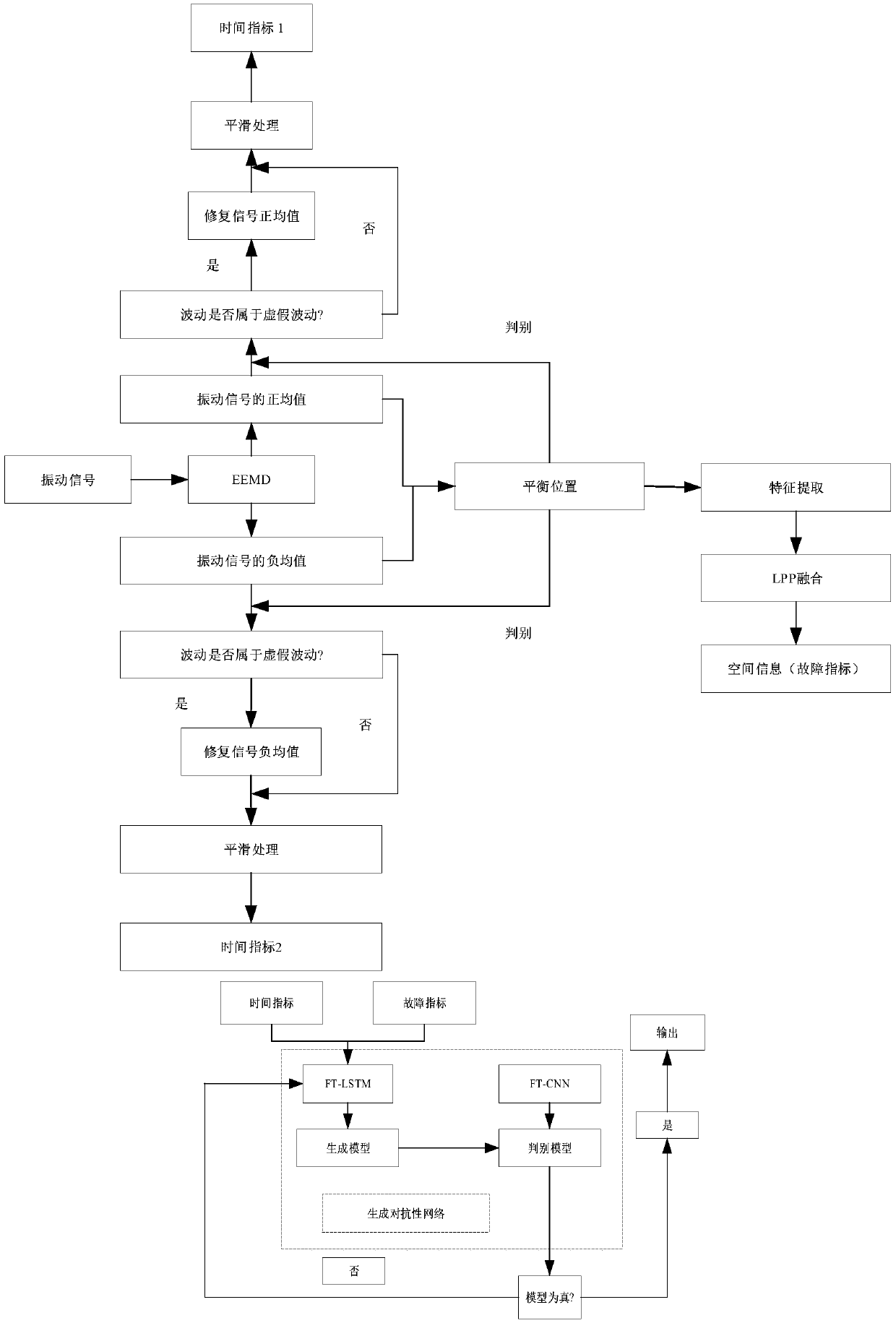

[0043] Such as Figure 1 to Figure 8 As shown, this embodiment describes a high-precision slewing bearing life evaluation method based on time-space sequence, including the following steps:

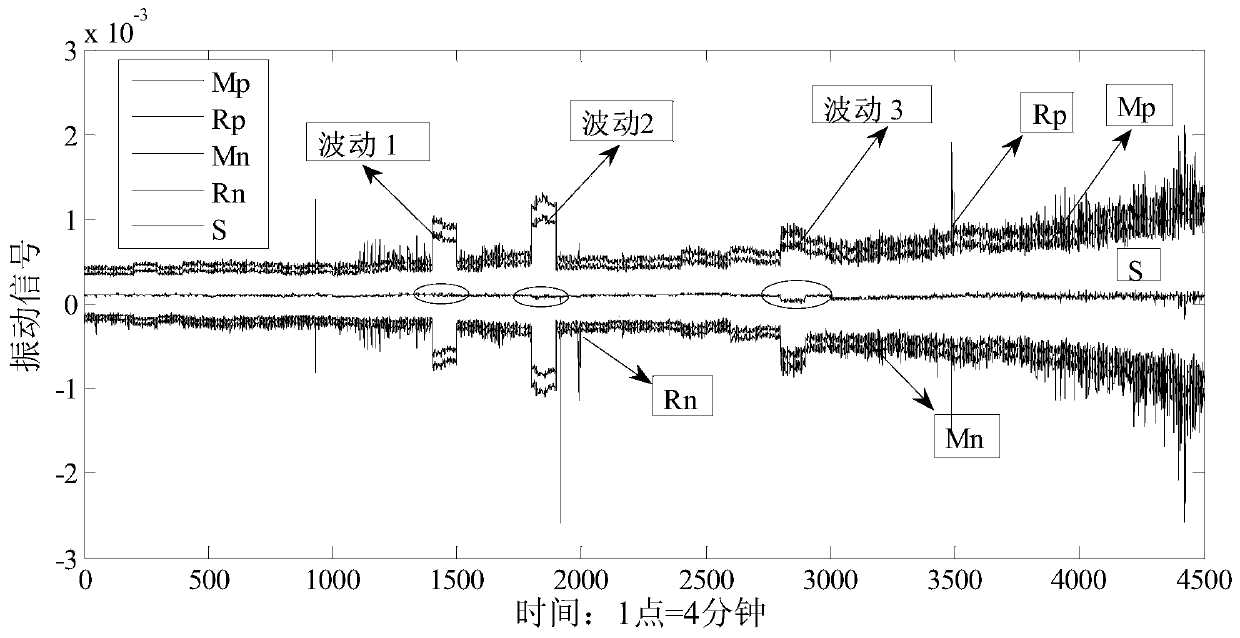

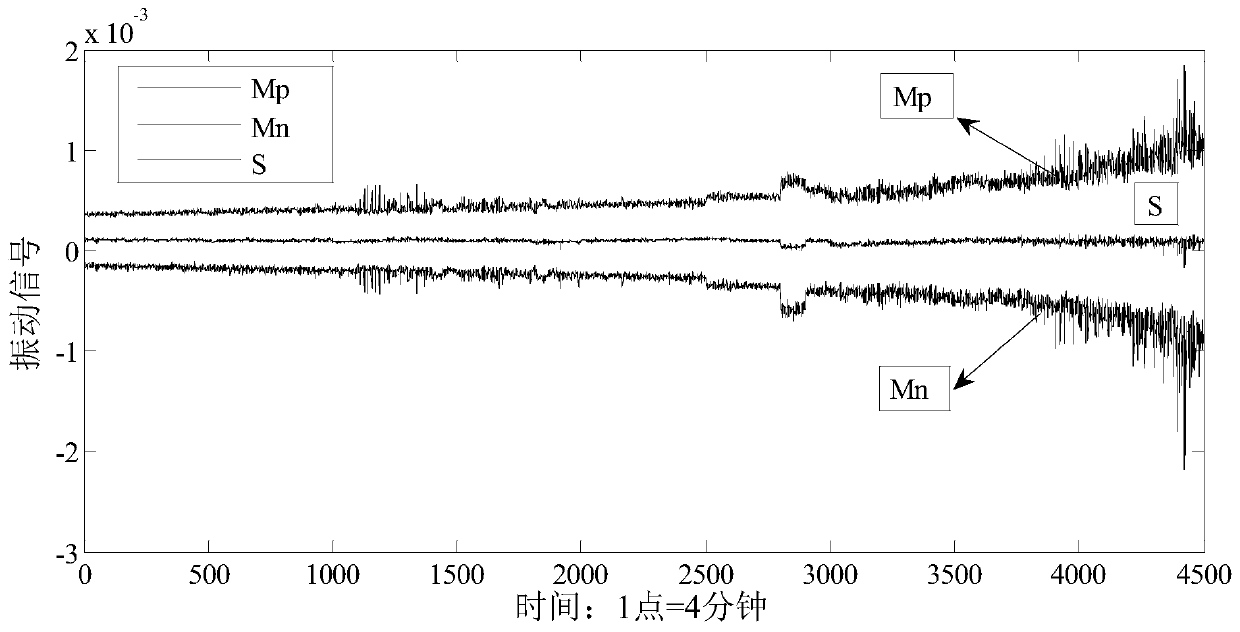

[0044] Step (1), obtaining space-time information: In this example, the slewing bearing of the self-developed slewing bearing test bench is used, and the loading adopts the loading method of step-by-step loading, and the multi-angle sensing measurement of the slewing bearing of the service part is carried out through the acceleration sensor; during the loading period, Create irregular noise signals for interference and simulate complex working conditions; then extract space-time information (Mp, Mn, S); where Mp represents the average value of positive vibration signals, Mn represents the average value of negative vibration signals, S represents the balance posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com