X-ray anode, x-ray emitter and method for producing an x-ray anode

A technology of X-rays and radiators, applied in the field of manufacturing X-ray anodes, can solve the problems of high backscattering rate, lowering the image quality of X-ray images, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

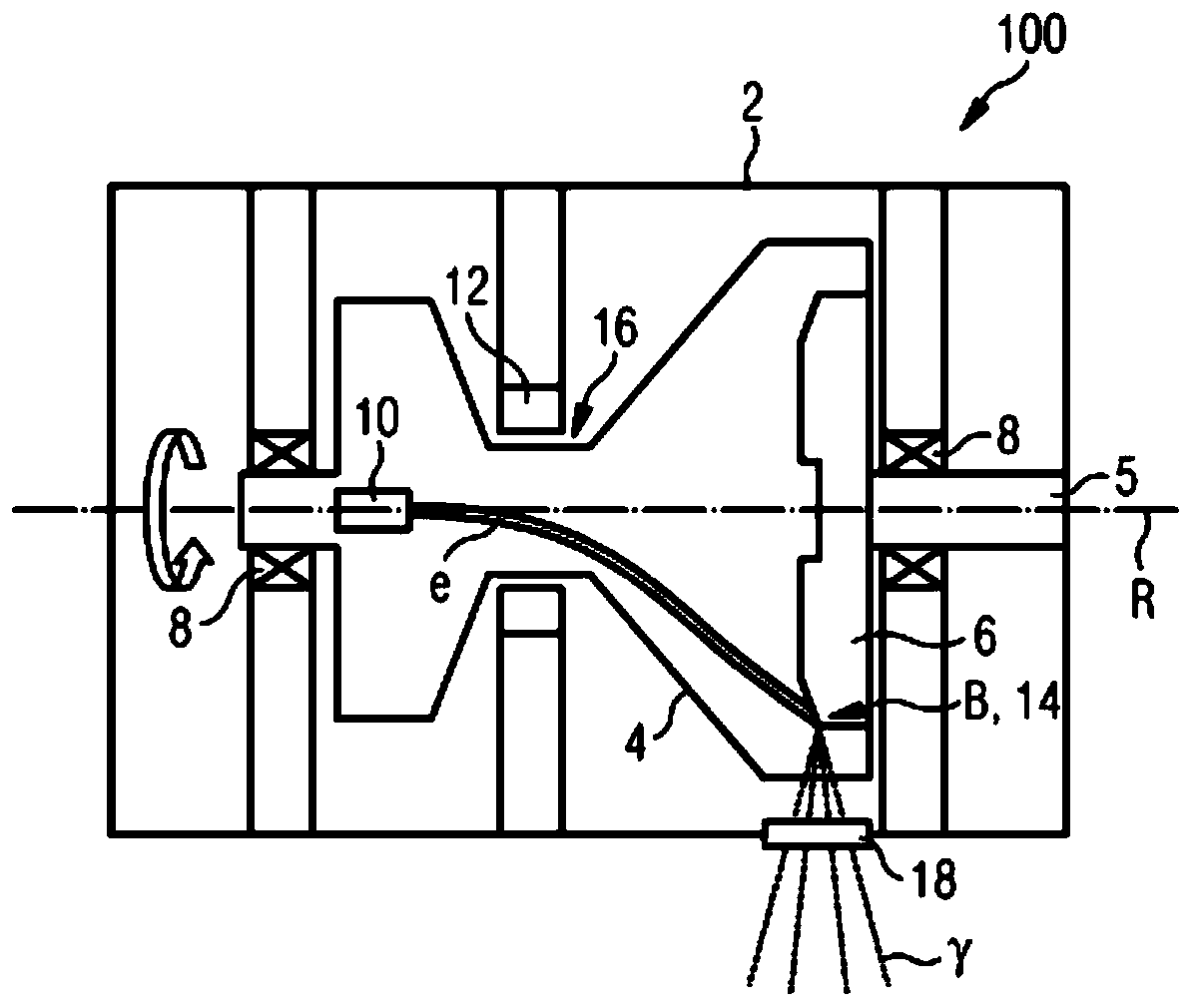

[0045] figure 1 Shown is an x-ray radiator 100 designed as a rotary piston radiator with a vacuum housing 4 mounted rotatably in a bearing 8 within a housing 2 . The housing 2 is typically filled or can be filled with a liquid coolant, in particular cooling oil, so that the vacuum housing 4 that rotates during operation is directly circulated by the coolant. The vacuum housing 4 can be set in a rotational movement about the axis of rotation R, for example via the shaft 5 .

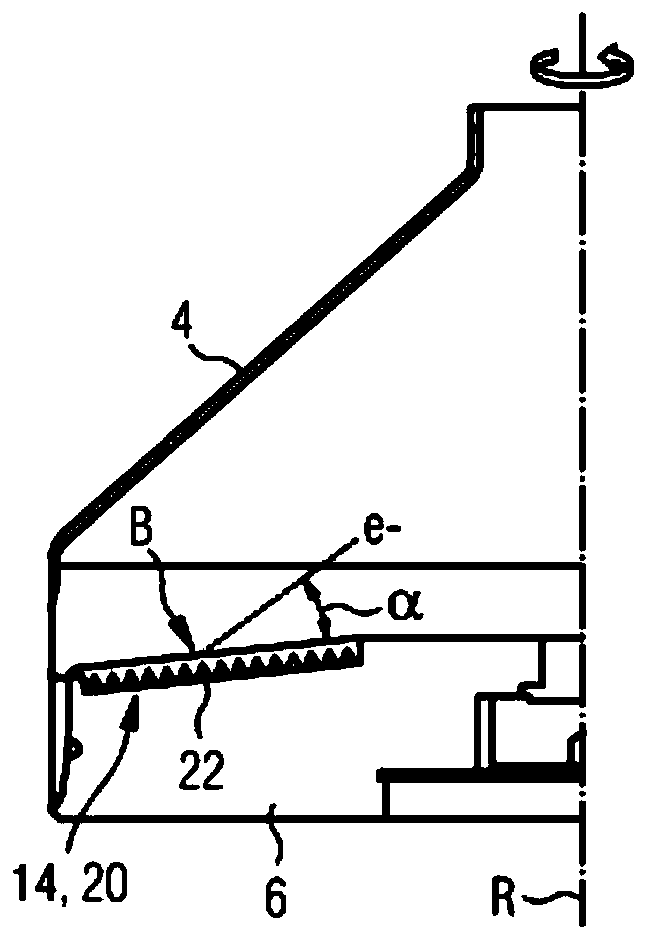

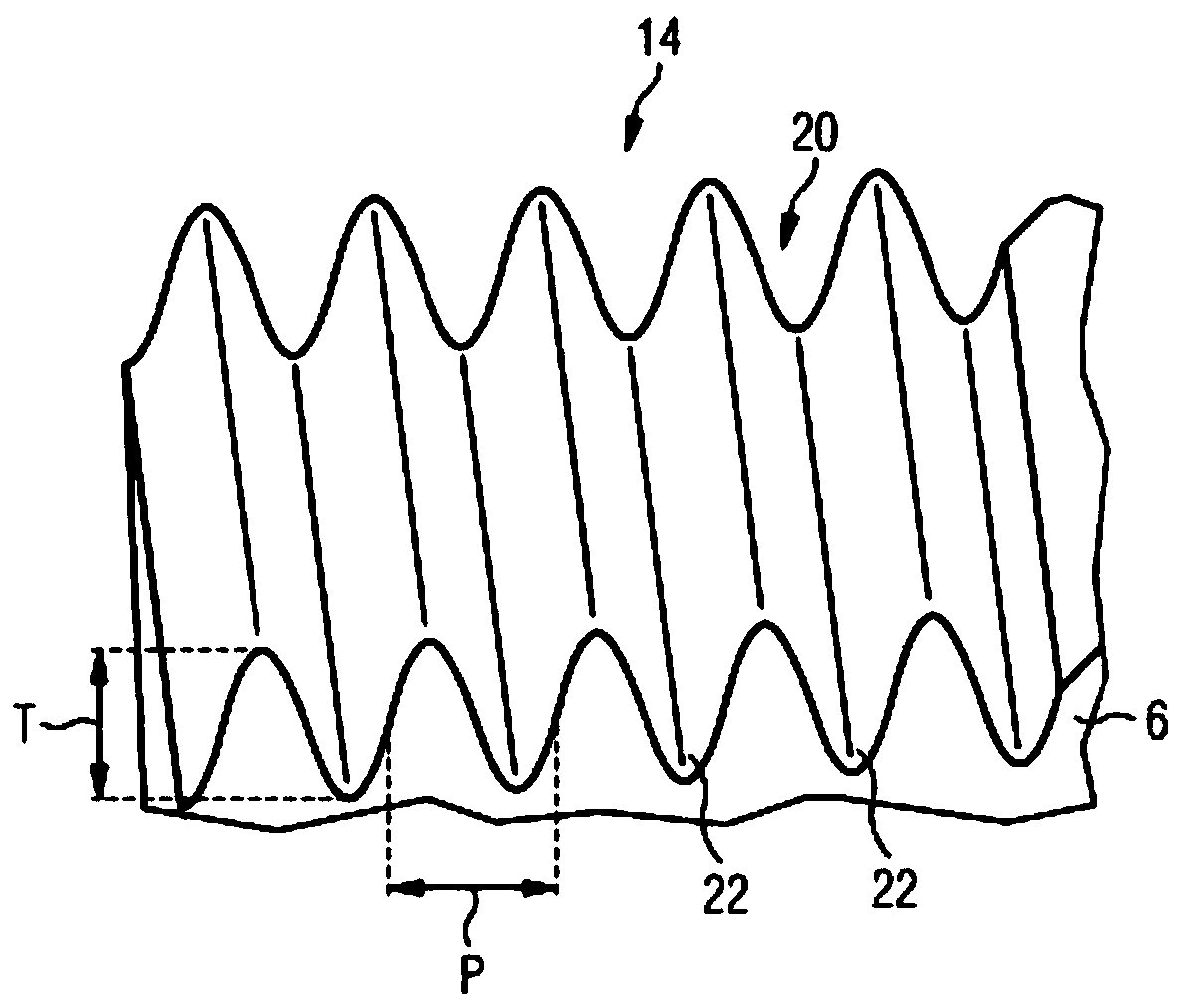

[0046] A part of the vacuum housing 4 is formed by a disk-shaped x-ray anode 6 which has an edge region intended to be loaded with electrons e. A high voltage is present between the x-ray anode 6 and the cathode 10 , so that the cathode 10 emits electrons e during operation, which are accelerated towards the x-ray anode 6 . In this case, the deflection device 12 , which in particular includes a plurality of magnetic deflection coils, deflects the electrons e onto suitable trajectories such that they stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com