Paddy field high-stubble double-shaft slurry-stirring stubble-burying grader

A high stubble, grader technology, applied in the direction of soil lifting machinery, agricultural machinery and implements, shovels, etc., can solve the problems of unstable output power, affecting the operation effect, delaying the farming time, etc., to increase work efficiency, good leveling effect, the effect of increasing the working width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

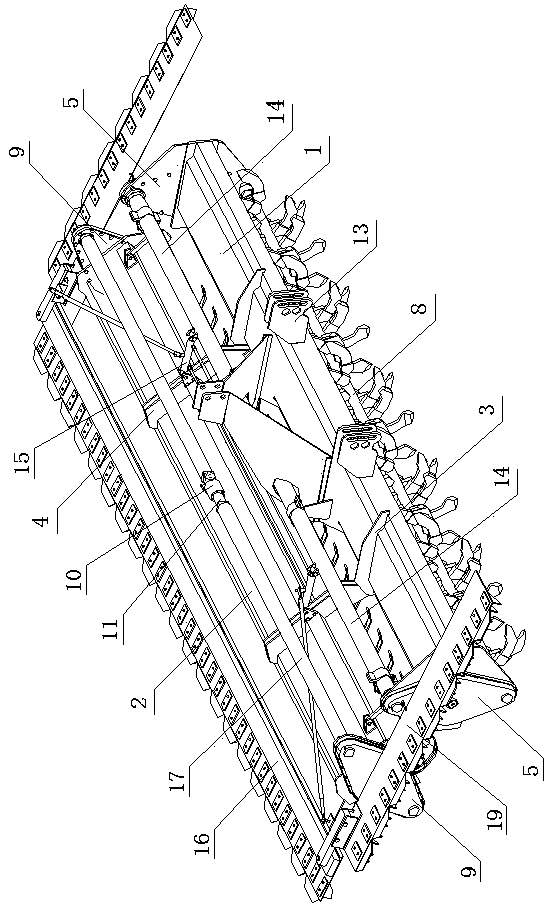

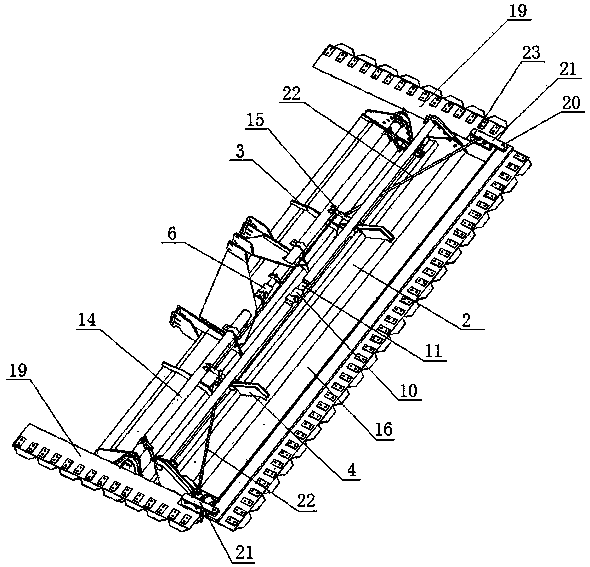

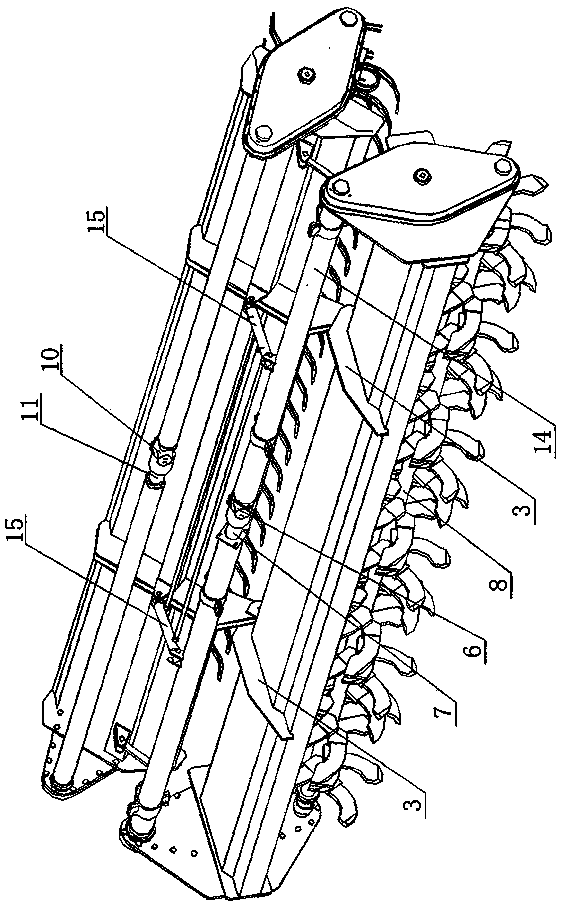

[0019] The paddy field high-stubble double-axis stirring stubble-burying machine of the present invention, such as figure 1 , figure 2 , image 3 As shown, it is composed of a cover plate, a beating knife roll and a stubble pressing knife roll. The beating knife roll is composed of a beating machete fixed on the beating knife shaft, and each pair of beating machetes is staggered by 72 degrees. 70 mm, five pairs of scimitars, with a distance of 70 mm between each group. The stubble pressing knife roller is composed of stubble pressing spring teeth fixed on the stubble pressing shaft.

[0020] The cover plate is composed of cover plate I1 and cover plate II2 in parallel, two fixed plates I3 are fixed on the cover plate I1, and fixed plates are provided on the position corresponding to the fixed plate I3 on the cover plate II2. Plate II4, fixed plate I3 and the ends of fixed plate II4 are hinged, so that cover plate II2 moves up and down with the end of fixed plate I3 as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com