Boiler flue gas desulfurization and denitrification equipment with anti-vibration structure

A boiler flue gas, desulfurization and denitrification technology, which is applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., to achieve the effects of ensuring anti-seismic performance, improving work efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

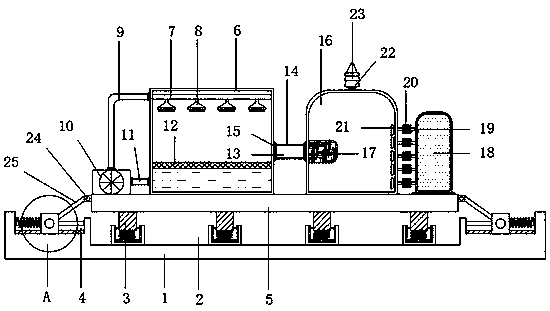

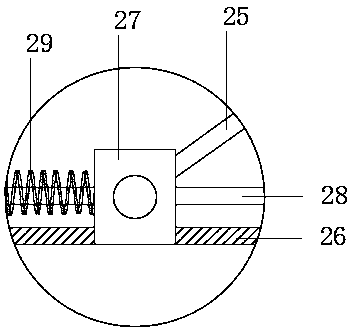

[0020] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a boiler flue gas desulfurization and denitrification equipment with an anti-seismic structure, including a load-bearing base 1, and a No. The inner bottom of the shock chamber 2 is evenly provided with a number of shock absorbing mechanisms 3, and the two sides of the load-bearing base 1 are provided with a No. 2 shock absorber 4, and the inner bottom of the No. A No. 1 slide block 27 is slidably connected to the No. 1 chute 26 .

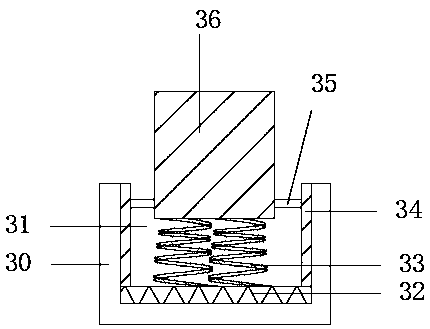

[0021] Wherein, the shock absorbing mechanism 3 is composed of a groove plate 30, a No. 2 buffer spring groove 31, a spring backing plate 32, a No. 2 buffer spring 33, a No. 2 chute 34, a No. 2 slider 35 and a movable connecting block 36. The bottom of the damping mechanism 3 is provided with a groove plate 30, the groove plate 30 is connected with the load-bearing base 1, the groove plate 30 is provided with a No. 2 buffer spring groove 31, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com