Automatic spraying system for pipe fitting bell and spigot

An automatic spraying and socket spraying technology, applied in the direction of spraying devices, can solve the problems of poor product consistency, inconvenient spraying, and high labor intensity, and achieve the effects of high product quality consistency, improved appearance quality, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

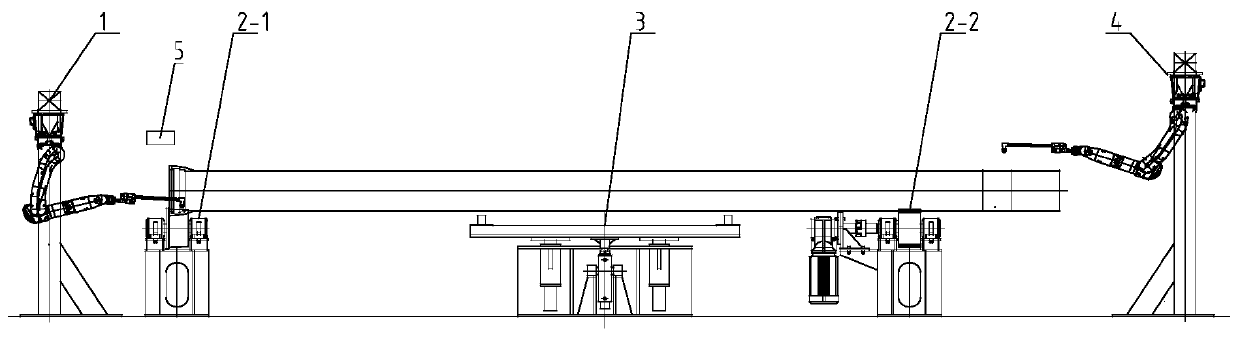

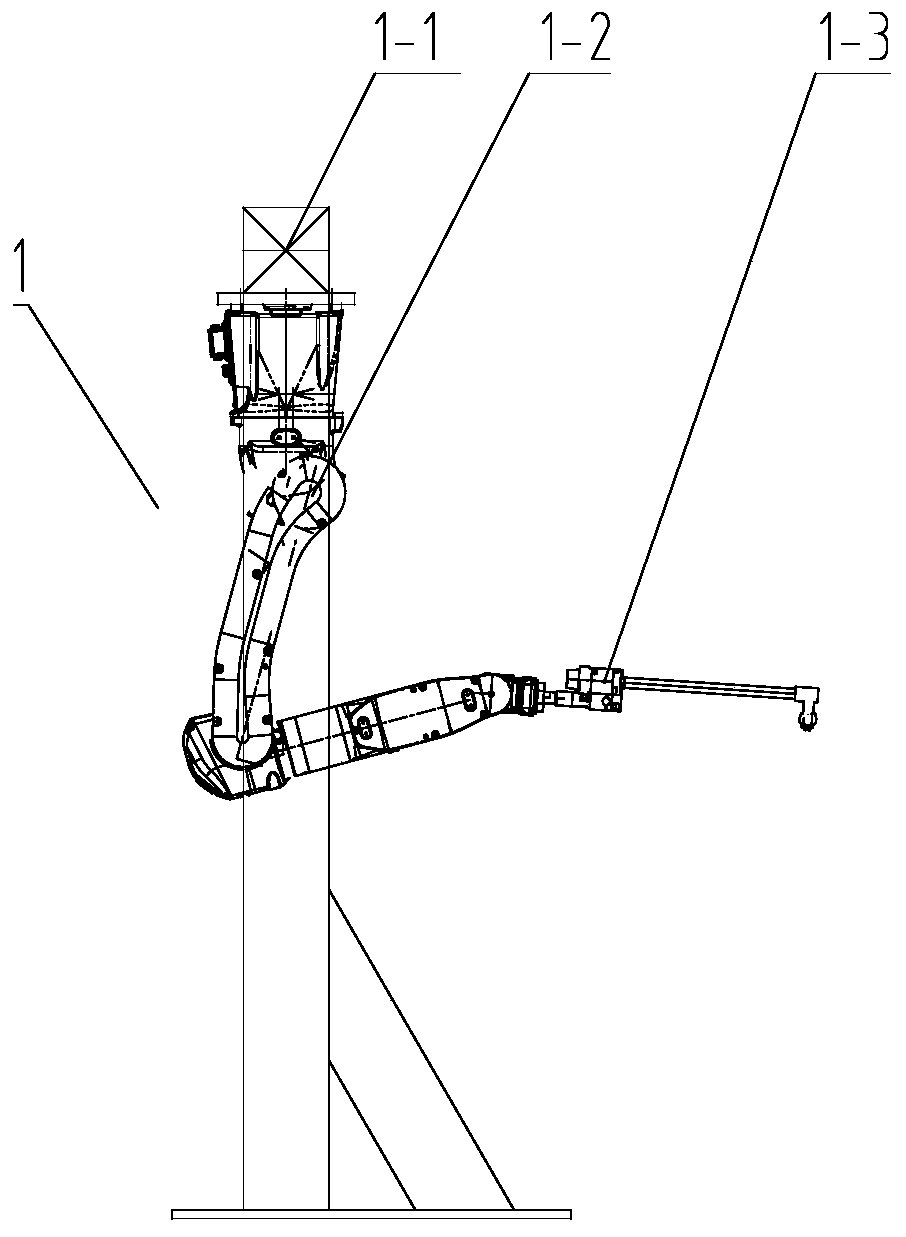

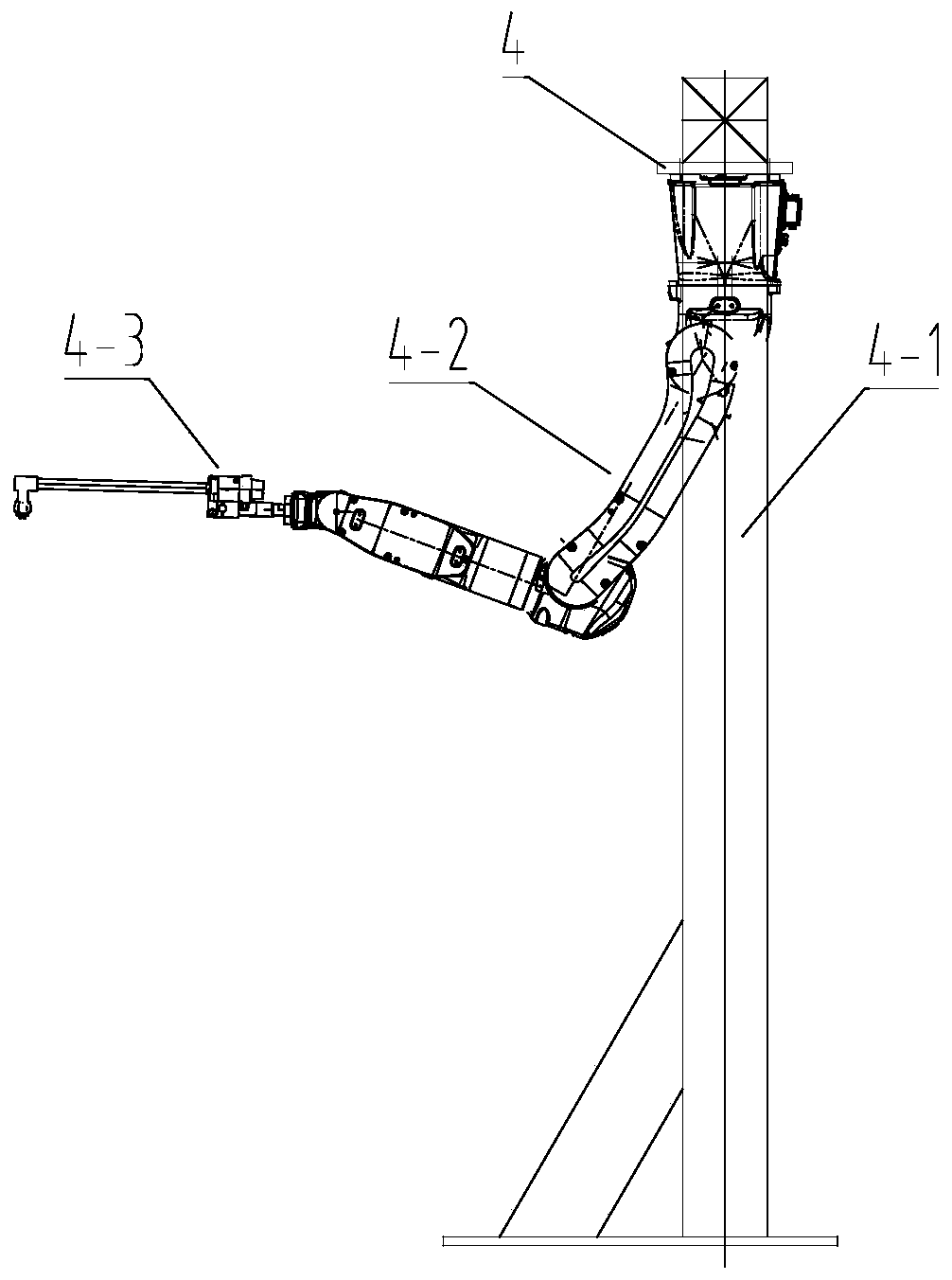

[0037] refer to Figure 1 to Figure 3 The first embodiment of the present invention provides an automatic spraying system for pipe fitting sockets, including a first robot 1 for spraying the inner wall of the pipe fitting socket and a second robot 4 for spraying the outer wall of the pipe fitting socket, and a rotating support for driving the pipe fittings to rotate A device 2, a lifting device 3 for lifting and lowering pipe fittings, and a pipe diameter detection device 5 for detecting pipe diameter information of the pipe fittings. In this embodiment, the cast pipe is used as an example for the pipe fitting, but in actual production, it can be applied to various pipe fittings that need to be sprayed on the socket.

[0038] Wherein, in this embodiment, because cast pipes are produced according to certain standards, the specifications of cast pipes corresponding to different pipe diameters are certain, so after the pipe diameter detection device 5 detects the pipe diameter in...

Embodiment 2

[0054] In this embodiment, similar to Embodiment 1, the pipe socket automatic spraying system includes a first robot 1 for spraying the inner wall of the pipe socket and a second robot 4 for spraying the outer wall of the pipe socket, used to drive the pipe The rotating rotary support device 2 is used for lifting and lowering the pipe fittings 3, and the pipe diameter detecting device 5 is used for detecting the pipe diameter information of the pipe fittings. The function of the above structure is similar to that of the first embodiment, so no more description is given here.

[0055] On the basis of Embodiment 1, in this embodiment, an extension rod is configured on the first spray gun 1-3 of the first robot 1 and the second spray gun 4-3 of the second robot. They are respectively installed on the first spraying manipulator 1-2 and the second spraying manipulator 4-2. By configuring the extension rod, the automatic spraying system for pipe fitting sockets in this embodiment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com