elutriator

An elutriator and elutriation technology, applied in the field of elutriator, can solve the problems of short residence time, large particle size range, and no good solution, and achieve the effect of low equipment failure rate and improved elutriation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1

[0101] The particle treatment objects are: PMMA particles with an average particle size of 3mm;

[0102] The processing capacity of all elutriators used is 15t / h.

Embodiment 1

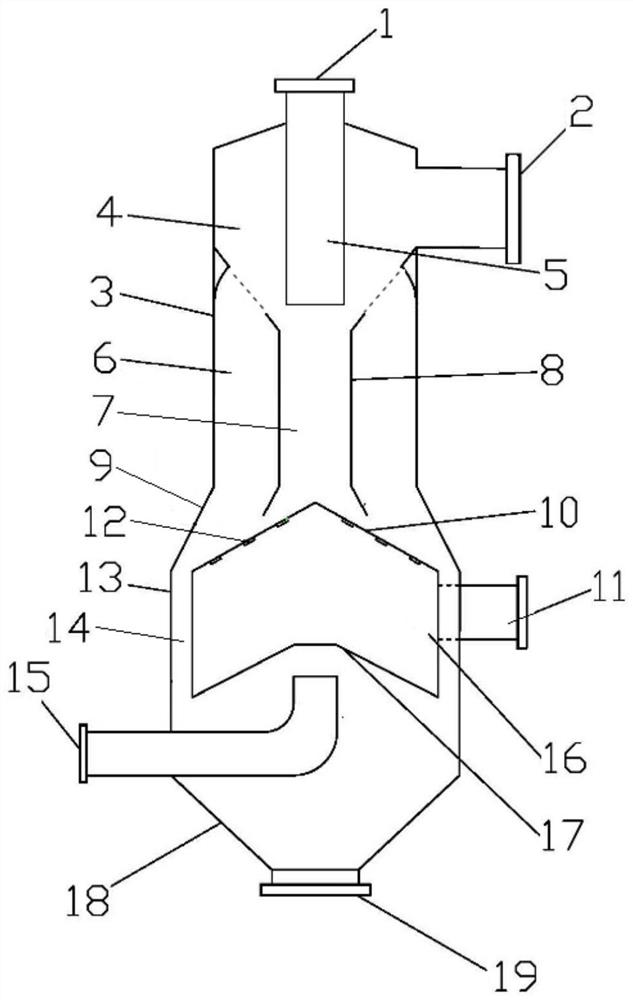

[0104] like Figure 1-4 As shown, the diameter of the particle inlet 1 is 200mm; the diameter of the elutriation section cylinder 3 is 700mm, and the height is 1200mm; the height of the frusto-conical cylinder 9 of the cleaning section is 175mm; 700mm, the height of the discharge cone 18 is 320mm;

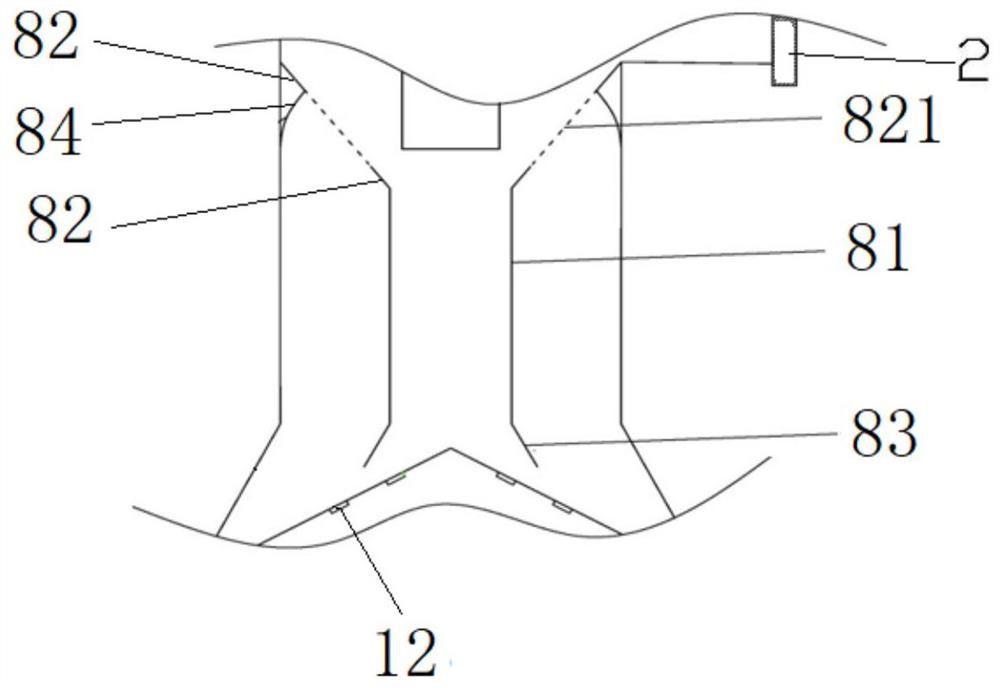

[0105] The diameter of the second enlarged diameter section 83 is 315mm; the vertical distance H from the end edge of the second enlarged diameter section 83 to the upper surface of the cleaning plate 10 2 100mm; Elutriation passage 7 diameters are 250mm, length is 500mm; The diameter of powder gas outlet 2 is 350mm, and the diameter of first gas inlet pipe 11 is 300mm, and the diameter of second gas inlet pipe 15 is 200mm, and the diameter of particle outlet 19 The diameter is 300mm;

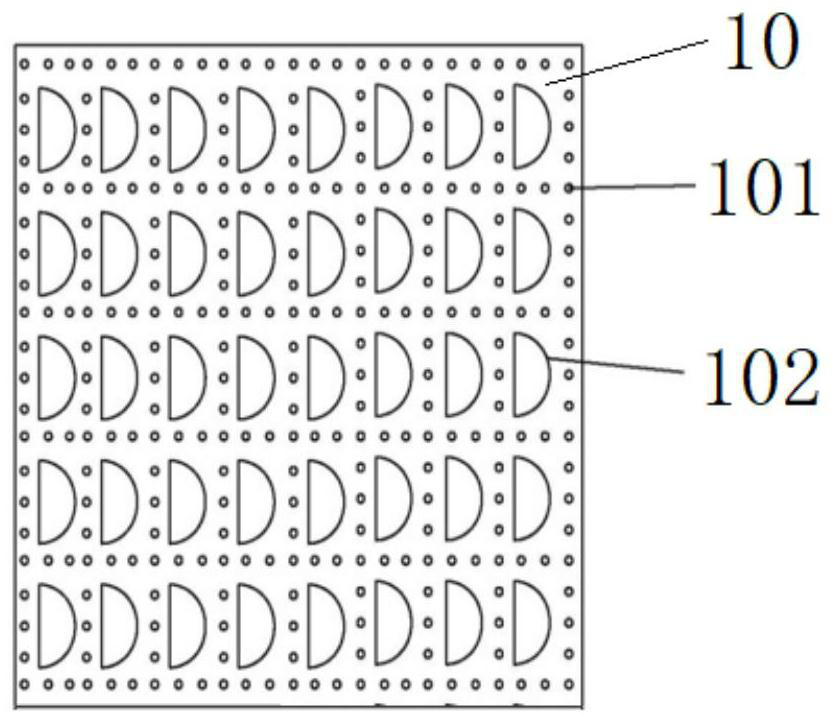

[0106]The included angle between the cleaning plate 10 and the horizontal direction is 30°, the cone surface radius of the cleaning plate 10 is 450 mm, the diameter of the first cleaning hole 101 ...

Embodiment 2

[0112] Only the following content is different from Example 1, and all the other contents and implementation process are the same as Example 1:

[0113] The diameter of the second enlarged diameter section 83 is 300 mm; the vertical distance H from the lower end edge of the second enlarged diameter section 83 to the upper surface of the cleaning plate 10 2 80mm; the elutriation channel 7 has a diameter of 250mm and a length of 550mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com