Rice washing device for rice processing

A rice processing and filtering device technology, applied in cleaning methods and utensils, cleaning methods using liquids, solid separation, etc., can solve the problems of inability to clean out rice grains, low efficiency, and a large amount of pure water, so as to improve quality and improve Efficiency, the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

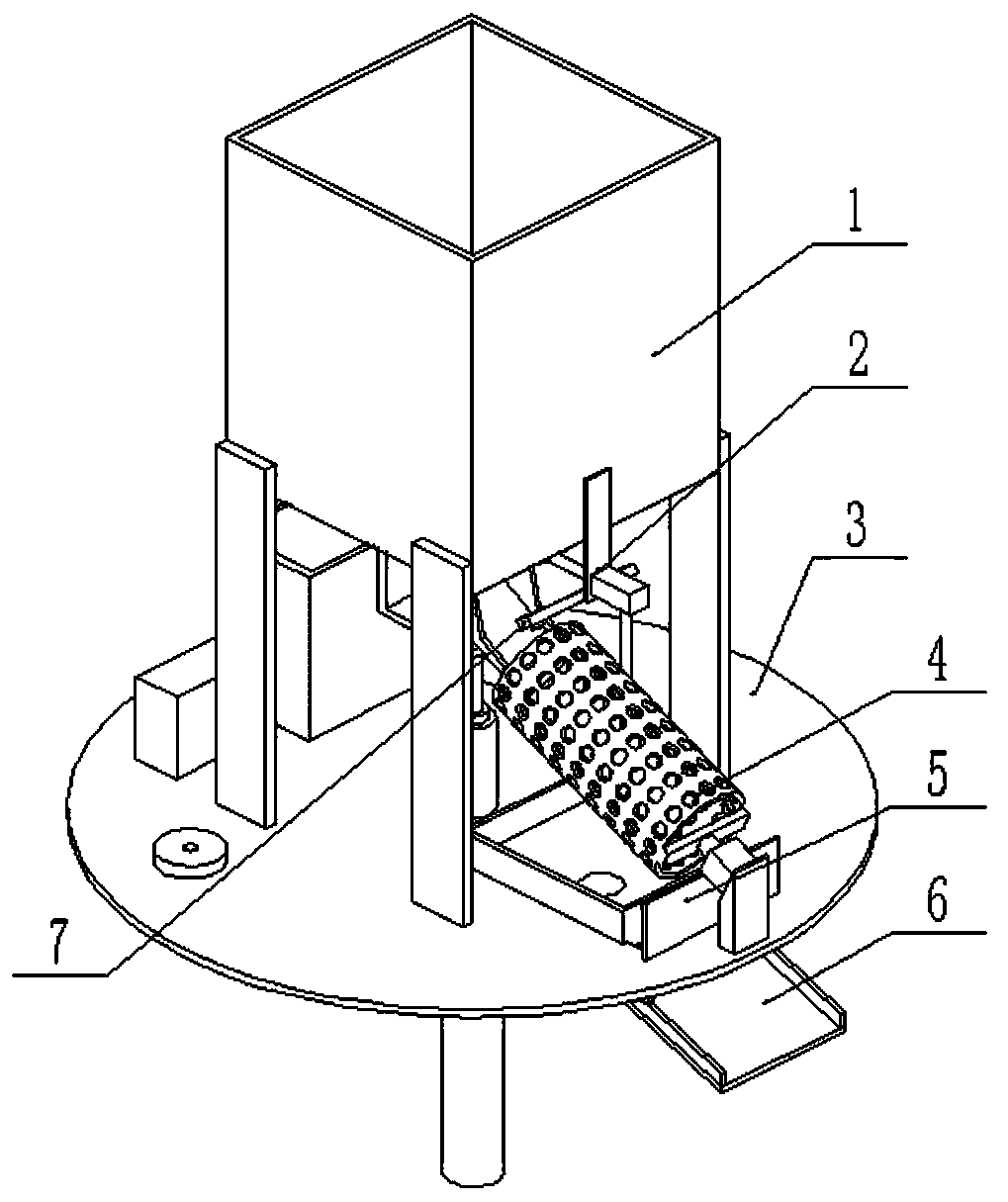

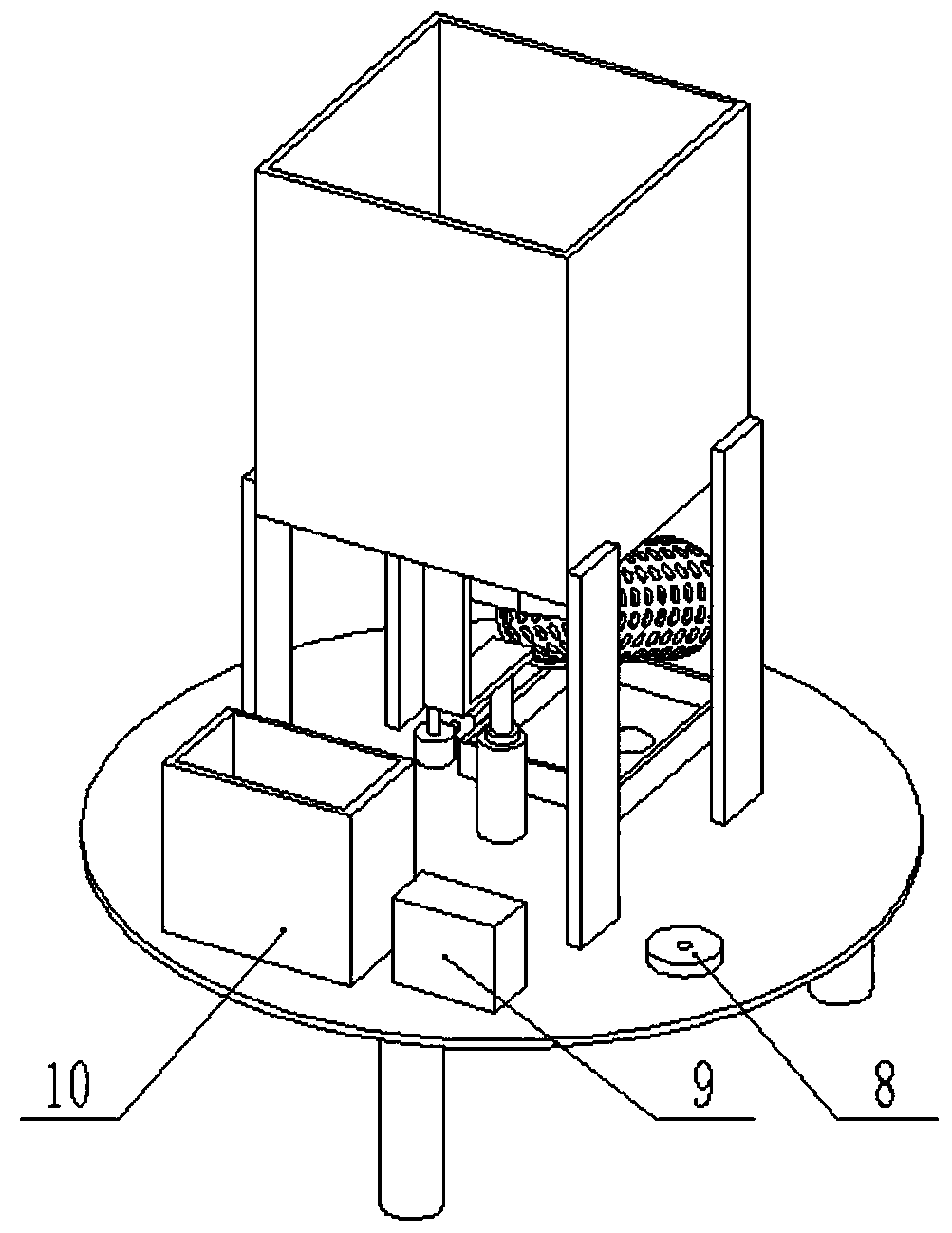

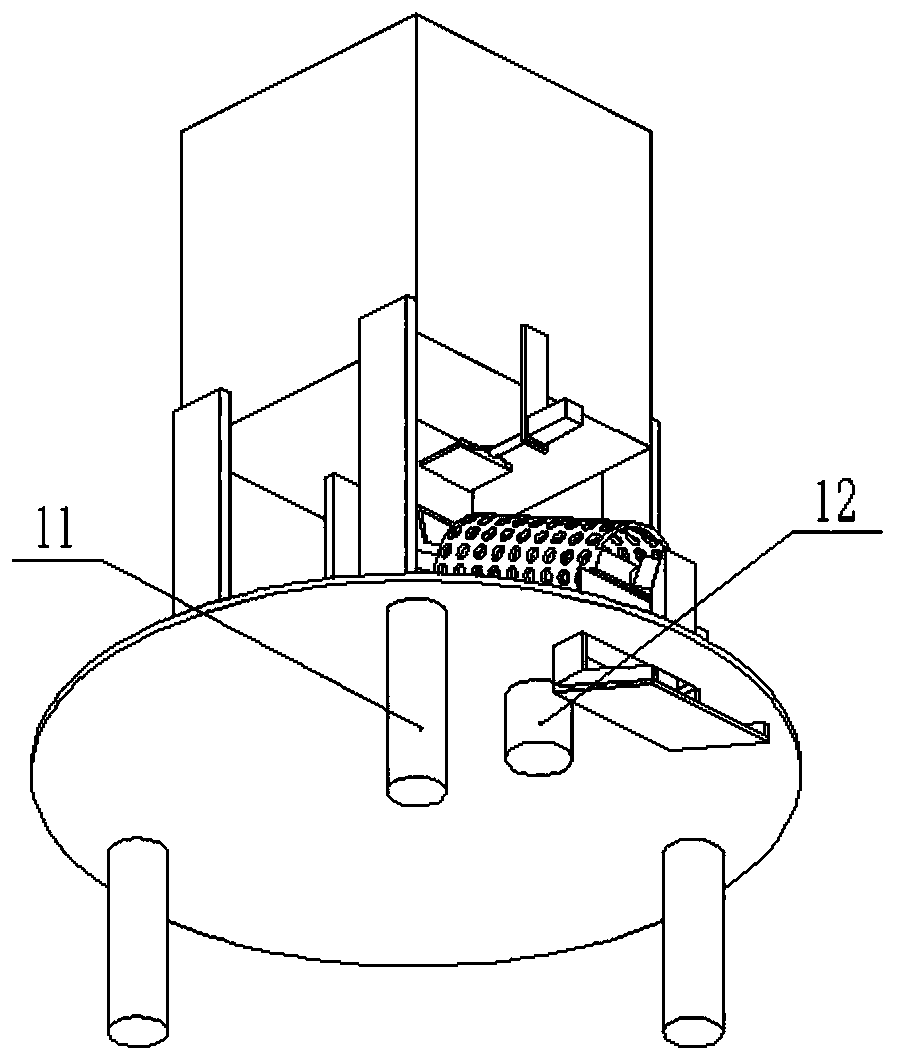

[0021] The present invention is realized through the following technical solutions: a rice washing device for rice processing, including a grain storage device 1, a rice discharge device 2, a workbench 3, a filter device 4, a baffle plate 5, a discharge port 6, and a water spray device 7 , alarm 8, controller 9, water tank 10, supporting legs 11 and water shielding tank 12, the grain storage device 1 is installed above the workbench 3, the rice output device 2 is installed on the grain storage device 1, the The workbench 3 is installed on the support leg 11, the filter device 4 is fixed above the workbench 3, the baffle plate 5 is fixed to the workbench 3, the discharge port 6 is installed above the workbench 3, and the The water spray device 7 is installed on the workbench 3, the alarm 8 is installed on the workbench 3, the controller 9 is fixed on the workbench 3, the water tank 10 is fixed on the workbench 3, and the supporting legs 11 is installed on the bottom of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com