Squeeze casting punch cooling device

A cooling device and squeeze casting technology, applied in the field of squeeze casting equipment, can solve problems such as the influence of injection process stability, reduced service life, and uneven cooling and heating of punches, so as to reduce labor costs, improve heat dissipation efficiency, reduce Effect of punch temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

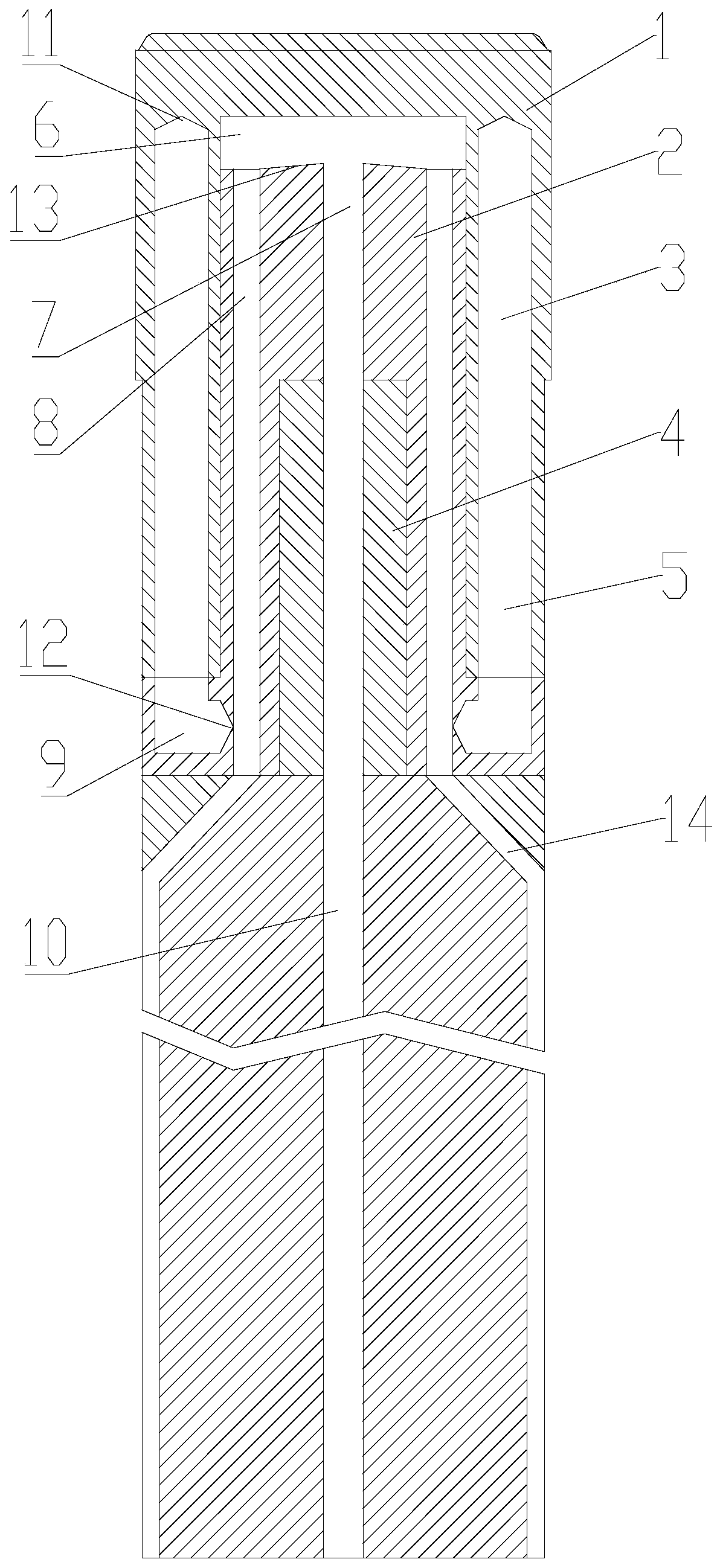

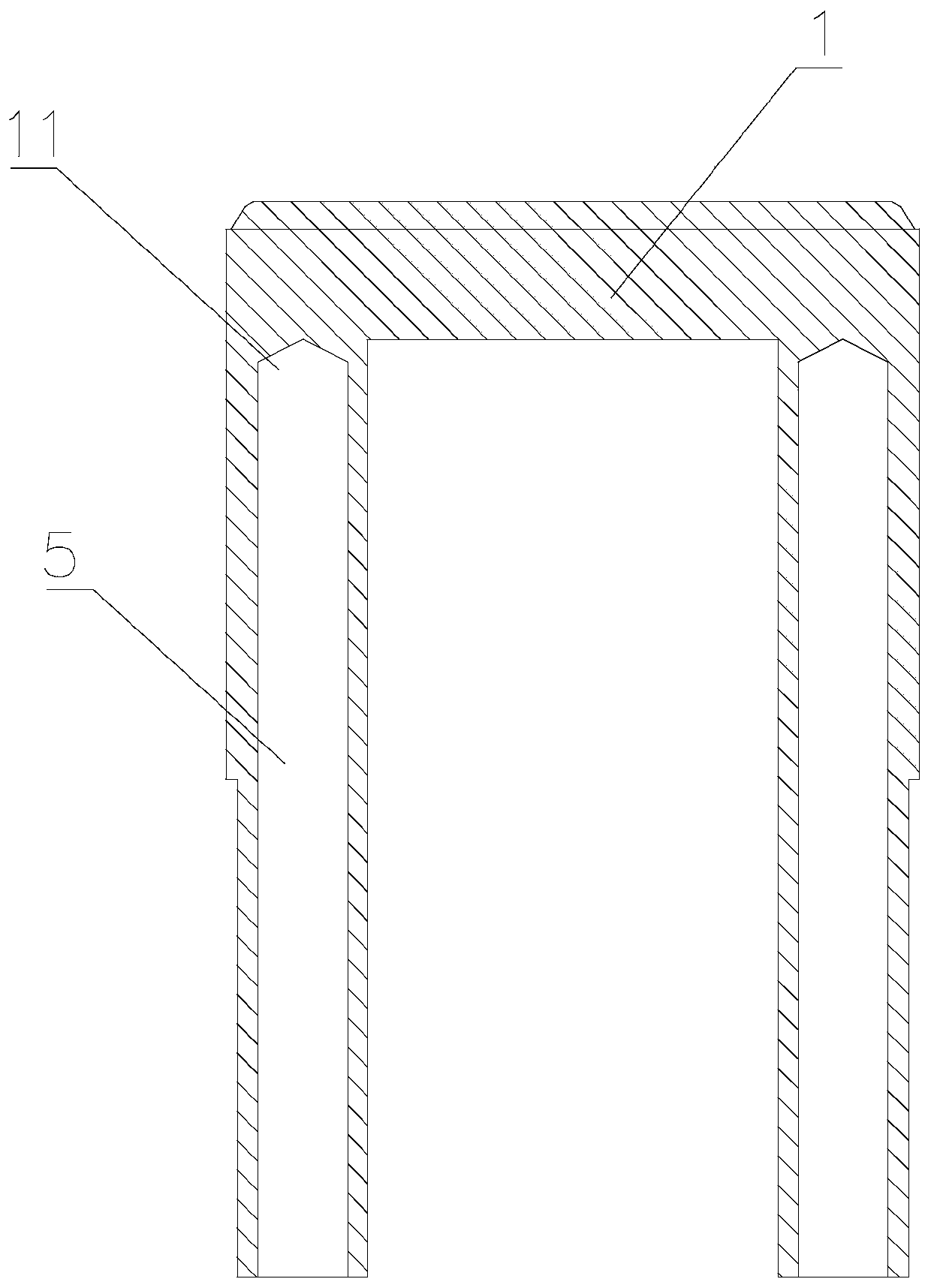

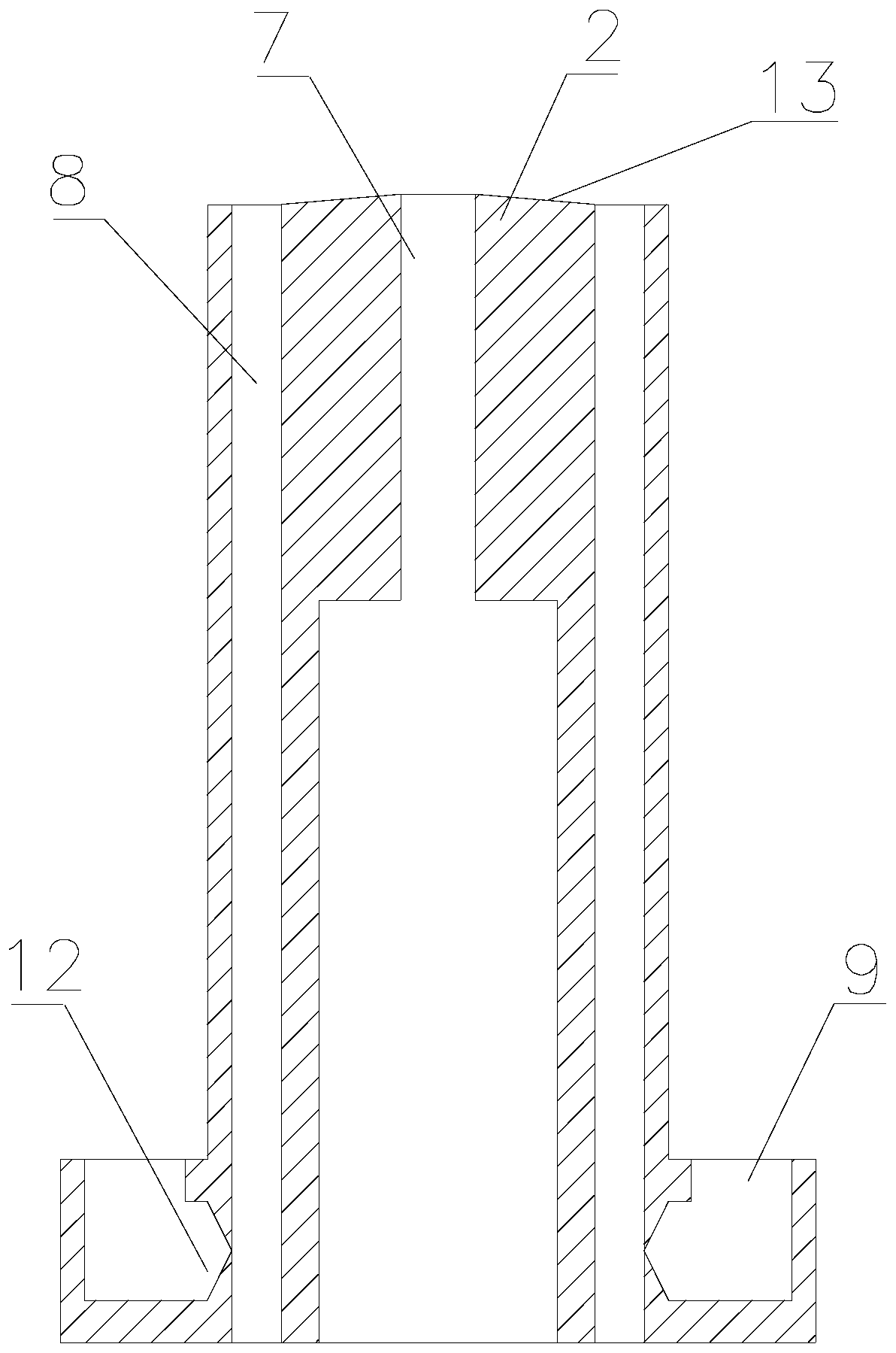

[0029] A cooling device for extrusion casting punches in this embodiment, such as figure 1 As shown, it includes an upper punch 1, a lower punch 2, a heat pipe 3 and a push rod 4, the upper punch and the lower punch are installed coaxially, a water storage area 6 is formed between the upper punch and the lower punch, and the push rod is installed on The lower part of the lower punch, the evaporation end of the heat pipe is installed in the upper punch, and the condensation end of the heat pipe is located in the lower punch. The evaporation end absorbs the heat of the upper punch, and conducts it to the lower punch to dissipate the heat. The lower punch can effectively support the upper punch, and the push rod can push the upper punch and the lower punch to move up and down. In order to ensure the tightness and avoid water leakage, the outer wall of the lower punch is axially sealed with the inner wall of the upper punch. There is a threaded hole at the center of the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com