Process for machining deep mounting hole of slewing bearing ring

A technology for slewing ring bearings and ferrules, which is applied in the technical field of processing bearing mounting holes, can solve the problems of adapter tool rod damage and scrapping, very high stability requirements, product damage and scrapping, etc., to eliminate risks and improve product quality. Stabilization and the effect of cutting amount reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

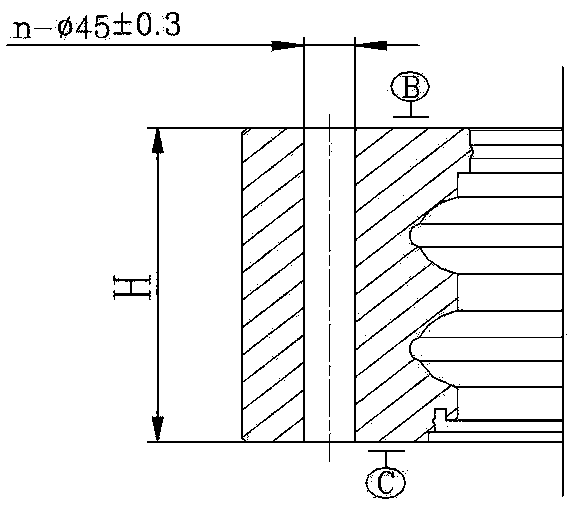

[0022] A process for processing the installation deep hole of the slewing ring bearing ring, which is used to process the installation hole with a diameter of φ45 in the finished product, and the steps include, as figure 1 As shown, the first hole is processed as a through hole, and the processing method of the first hole is to use a flexible drill that meets the requirements to drill directly from the B surface at one time. All dimensions in the drawings are in mm.

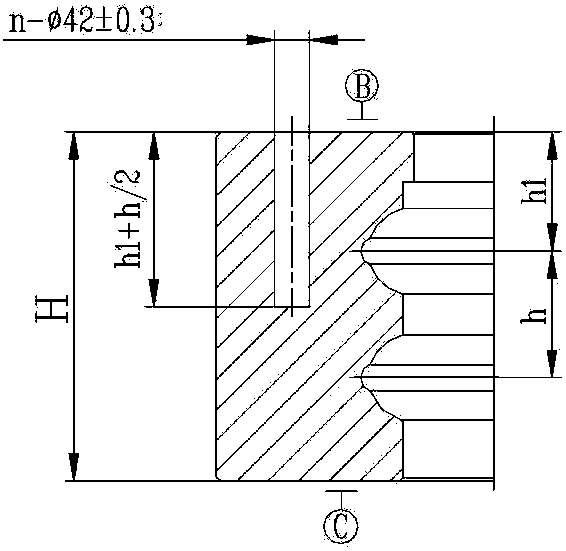

[0023] Such as figure 2 As shown, the remaining holes are first processed with a φ42mm U-drill, the processing depth is h2, the height of the slewing ring bearing is H, H>h2, and the processing depth h2 is about half of the end face height.

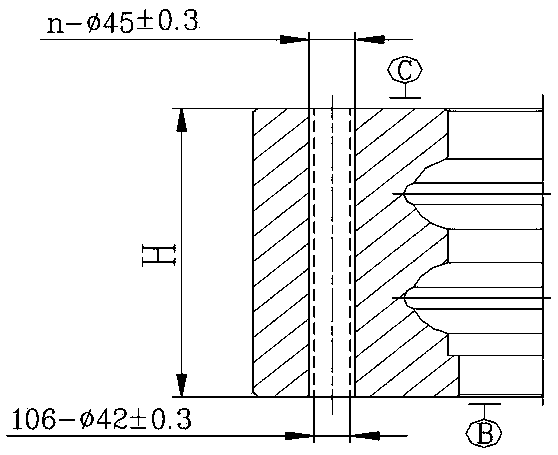

[0024] Such as image 3 As shown, after processing, turn the material and align it with the specified benchmark, then align it with the first hole, determine the zero point position (the starting position of processing, the angle is 0° at this time), and then use a φ42mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com