Intelligent production line for disassembling and assembling container freight yard station

A container and freight yard technology, applied in the field of disassembly and assembly intelligent production lines of container freight yards, can solve problems such as personnel safety, life safety accidents, and high labor costs, and achieve improved operating efficiency, safety and environmental protection, and labor low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

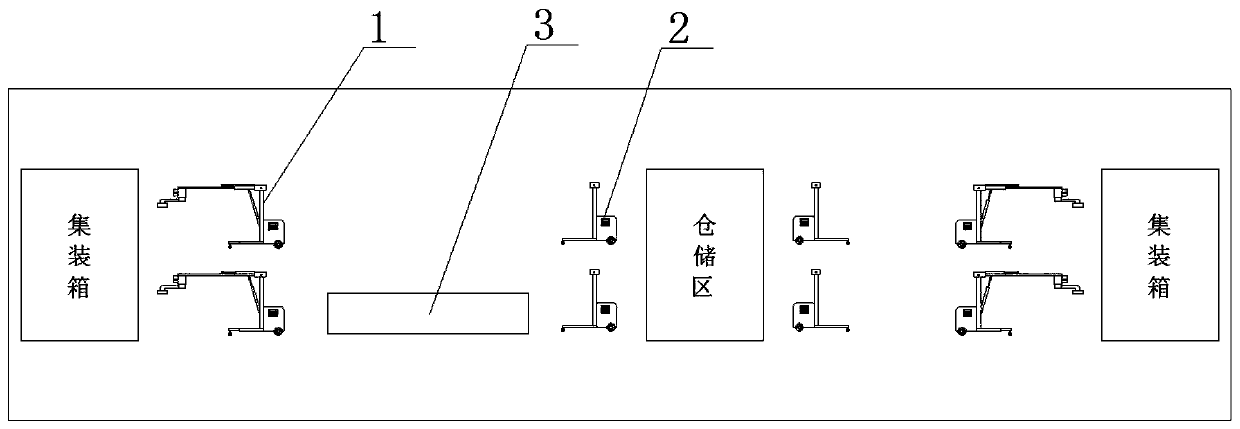

[0033] As a preferred embodiment of the present invention, the intelligent AGV palletizing and grabbing robot 1 can work in a container.

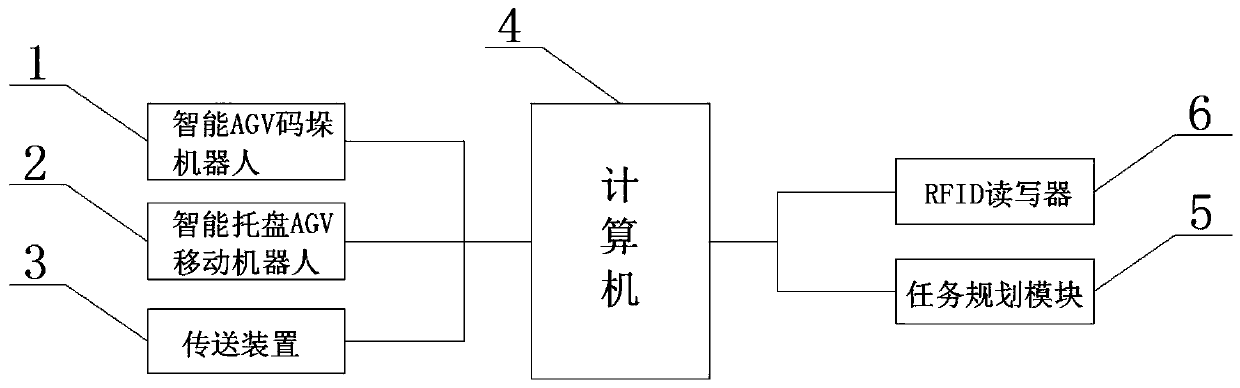

[0034] As a preferred embodiment of the present invention, the computer 4 communicates with the intelligent AGV palletizing and grabbing robot 1 , the intelligent tray AGV mobile robot 2 , the conveying device 3 and the RFID reader 6 in a wireless communication manner.

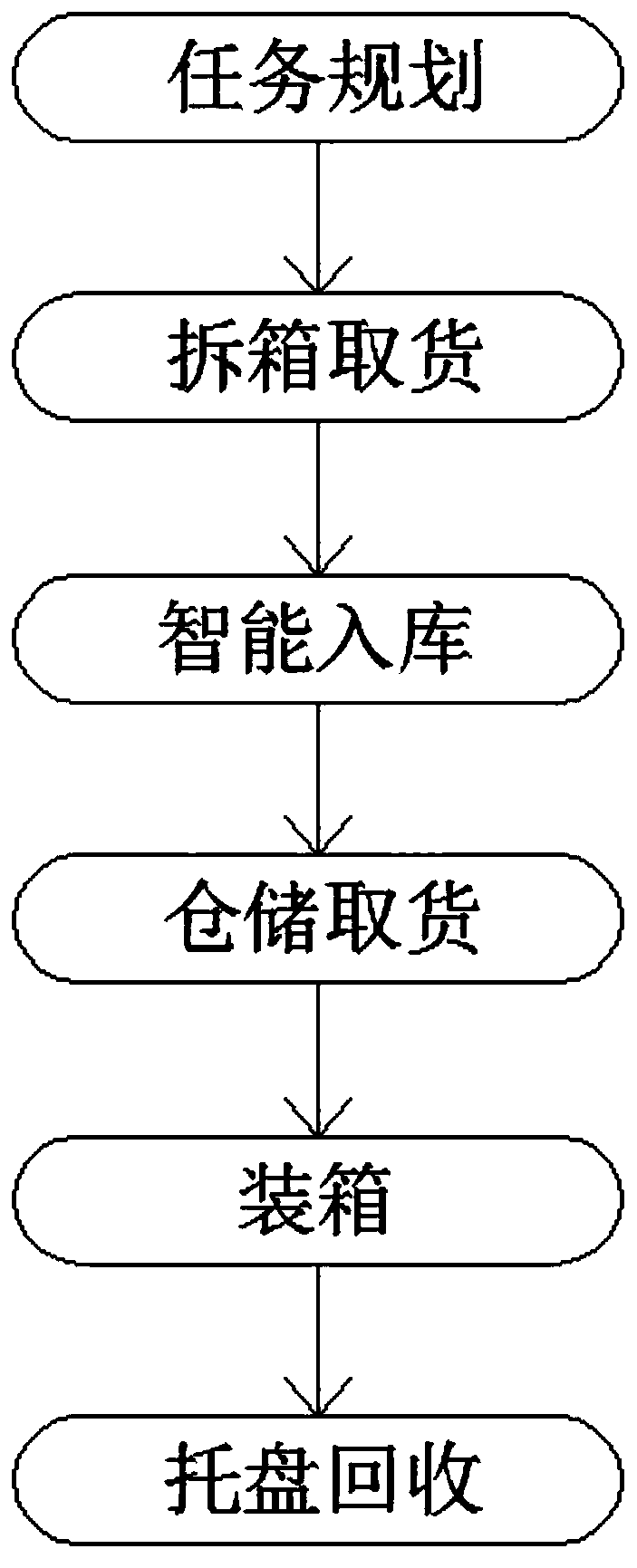

[0035]Working principle: The task planning module 5 allocates each robot in real time according to the use of the intelligent AGV palletizing and grabbing robot 1 and the intelligent pallet AGV mobile robot 2, as well as the material stock, purchase volume and shipment volume, so that each intelligent robot can be allocated reasonably, Coordinate task planning, optimize scheduling, and improve operating efficiency. The intelligent AGV palletizing and grabbing robot 1 takes out the container goods and loads them into pallets, and then transports them to the intelligent pallet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com