Washable energy-storage polar fleece knitted fabric and production process thereof

A technology for knitted fabrics and production processes, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of shortened service life, performance degradation, and size changes of sweaters, and achieve excellent washing resistance, good bulkiness, and thermal insulation. Performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

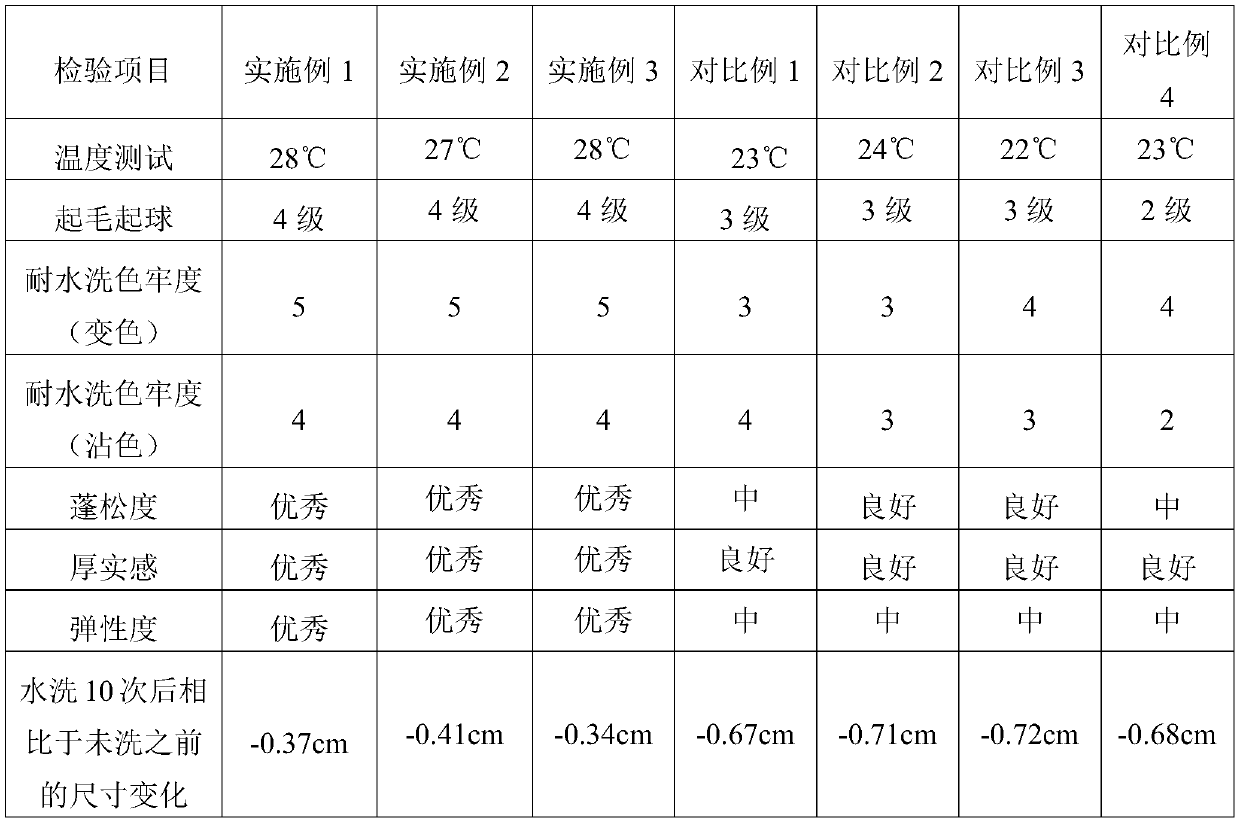

Examples

Embodiment 1

[0033] A washable energy storage fleece knitted fabric, the washable energy storage fleece knitted fabric is woven from the following materials according to the mass ratio:

[0034] EASY WARM POLY thermal storage yarn 25 parts

[0035] 150D / 144F SD DTY POLY polyester 35 parts

[0036] 30S / 1 cotton 35 parts.

[0037] Among them, the thermal storage yarn comes from Huamao Company, the 150D / 144F SD DTY POLY polyester comes from Baihong Company, and the cotton comes from Weiqiao Company.

[0038] The production process of the above-mentioned water-resistant energy-storage fleece knitted fabric is composed of the following steps: weaving, pre-ordering, dyeing, peracid neutralization, color fixing and softening, water rolling, setting machine drying, wool picking, carding, shearing, Shake pellets and make finished products.

[0039] Among them, the solid color soft formula is:

[0040] Active color fixing agent KH-9800 0.3%

[0041] Raising Oil 2.0%

[0042] Soft oil LB-900 8%...

Embodiment 2

[0054] A washable energy storage fleece knitted fabric, the washable energy storage fleece knitted fabric is woven from the following materials according to the mass ratio:

[0055] EASY WARM POLY thermal storage yarn 30 parts

[0056] 75D / 36F SD DTY POLY polyester 45 parts

[0057] 30S / 1 cotton 45 parts.

[0058] Among them, the thermal storage yarn comes from Huamao Company, the 75D / 36F SD DTY POLY polyester comes from Baihong Company, and the cotton comes from Weiqiao Company.

[0059] A production process of water-resistant energy-storage fleece knitted fabric, which is composed of the following steps: weaving, pre-ordering, dyeing, peracid neutralization, color fixing and softening, water rolling, setting machine drying, wool picking, carding, shearing , shaking pellets, and made into finished products.

[0060] Among them, the solid color soft formula is:

[0061] Active color fixing agent KH-9800 0.4%

[0062] Raising Oil 3.0%

[0063] Soft Oil LB-900 10%

[0064...

Embodiment 3

[0075] A washable energy storage fleece knitted fabric, the washable energy storage fleece knitted fabric is woven from the following materials according to the mass ratio:

[0076] EASY WARM POLY thermal storage yarn 27 parts

[0077] 75D / 36F SD DTY POLY polyester 40 parts

[0078] 30S / 1 cotton 40 parts.

[0079] Among them, the thermal storage yarn comes from Huamao Company, the 75D / 36F SD DTY POLY polyester comes from Baihong Company, and the cotton comes from Weiqiao Company.

[0080] A production process of water-resistant energy-storage fleece knitted fabric, which is composed of the following steps: weaving, pre-ordering, dyeing, peracid neutralization, color fixing and softening, water rolling, setting machine drying, wool picking, carding, shearing , shaking pellets, and made into finished products.

[0081] Among them, the solid color soft formula is:

[0082] Active color fixing agent KH-9800 0.35%

[0083] Raising Oil 2.5%

[0084] Soft Oil LB-900 9%

[0085...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com