Grey fabric bleaching and dyeing device

A gray cloth, bleaching and dyeing technology, applied in the direction of processing textile materials equipment configuration, processing textile material carriers, processing textile material containers, etc., can solve the problems of high labor intensity, difficult cloth traction, etc., to avoid polluting the ground, facilitate interweaving, and reduce resources wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

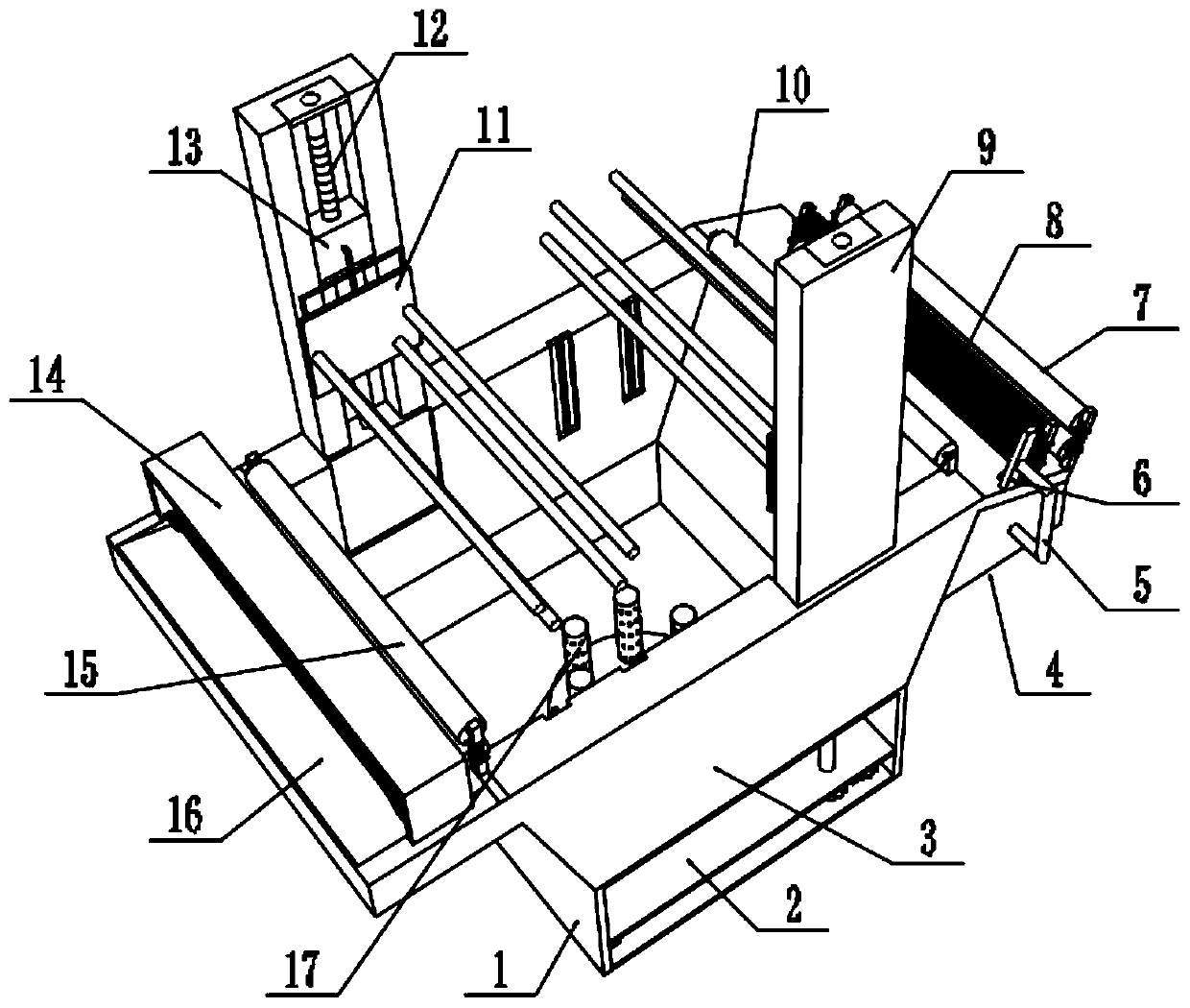

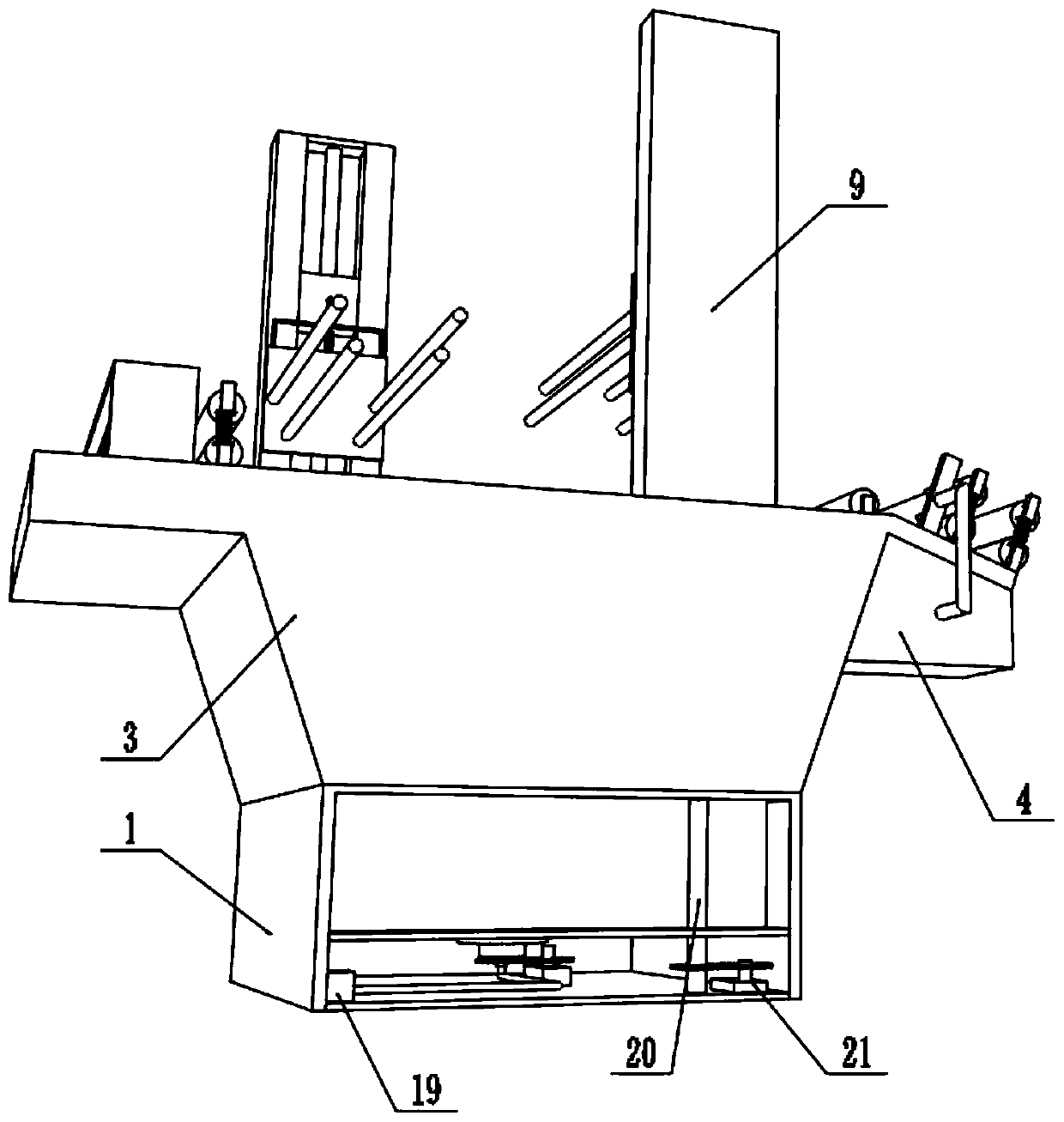

[0033] A gray cloth bleaching and dyeing device, such as Figure 1-5 As shown, it includes a bottom box 1 and a bleaching and dyeing pool 3, and the bleaching and dyeing pool 3 is welded on the top of the bottom box 1;

[0034] Both sides of the top of the bleaching and dyeing pool 3 are welded with a fixed frame 9, and a connecting plate 11 is fixed in the fixed frame 9 through a lifting assembly. The roller is raised to facilitate the interweaving of the cloth and reduce the difficulty of interweaving the cloth;

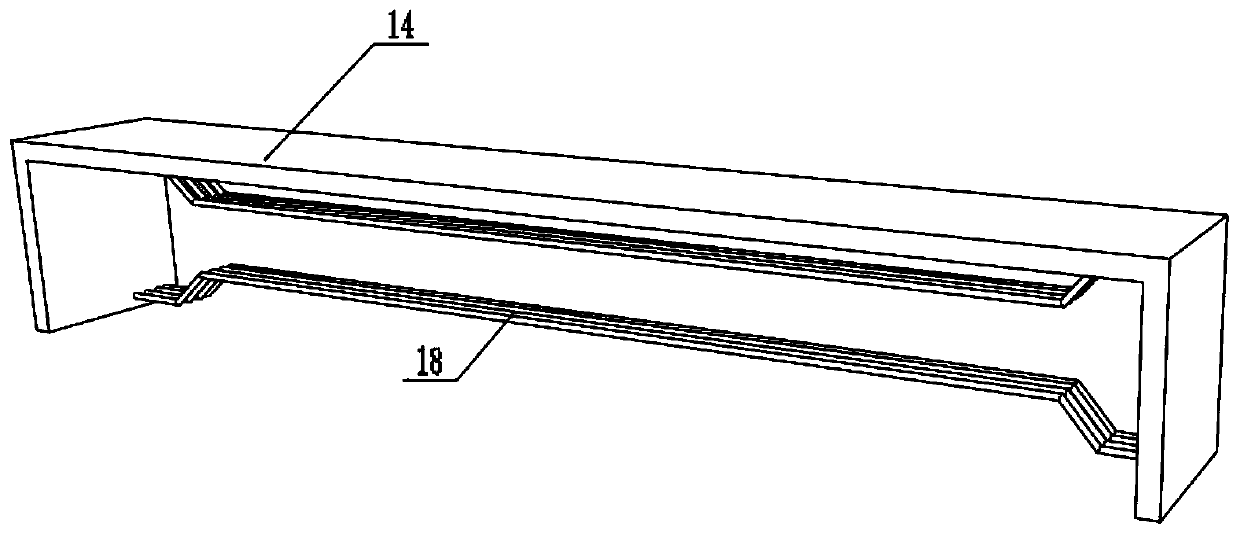

[0035] Both sides of the top of the bleaching and dyeing pool 3 are welded with side platforms, and the top of one of the side platforms is provided with a first cloth guide frame 7, a protective roller 10 and a deballing frame 8, and the other side platform is provided with a second guide frame. Cloth frame 15 and support 14, cloth passes through first cloth guide frame 7, protection roller 10 and guide roller and second cloth guide frame 15, can guide cloth accu...

Embodiment 2

[0042] A gray cloth bleaching and dyeing device, such as figure 1 , Figure 4 with Image 6 As shown, in order to solve the problem of poor printing and dyeing quality due to pilling or more dust on the surface of the cloth; this embodiment makes the following improvements on the basis of Embodiment 1: the ball removal frame 8 includes two shock mounts and two A ball removal mechanism, the shock absorber includes two side frames 34 and a spring 35, the spring 35 is welded to the outer walls of the two side frames 34, and the ball removal mechanism includes two net covers 33, welded between the two net covers 33 There is the same inner plate 31, the inner wall of the inner plate 31 is rotatably connected with several rotating rods 30, the top and the bottom of the rotating rod 30 are provided with rotating knives 32, the inner plate 31 is embedded with a motor, and the motor is connected to the rotating rod through the gear. The rod 30 forms a transmission fit; in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com