A prefabricated staircase for building construction and its installation method

A technology for buildings and stairs, which is applied in the field of prefabricated stairs and their installation in house construction, which can solve the problems of low mold reuse rate of prefabricated stairs, low standardization of prefabricated stairs, and heavy workload of designers, so as to shorten time and cost and improve stability Sexuality and load-bearing capacity, the effect of improving connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

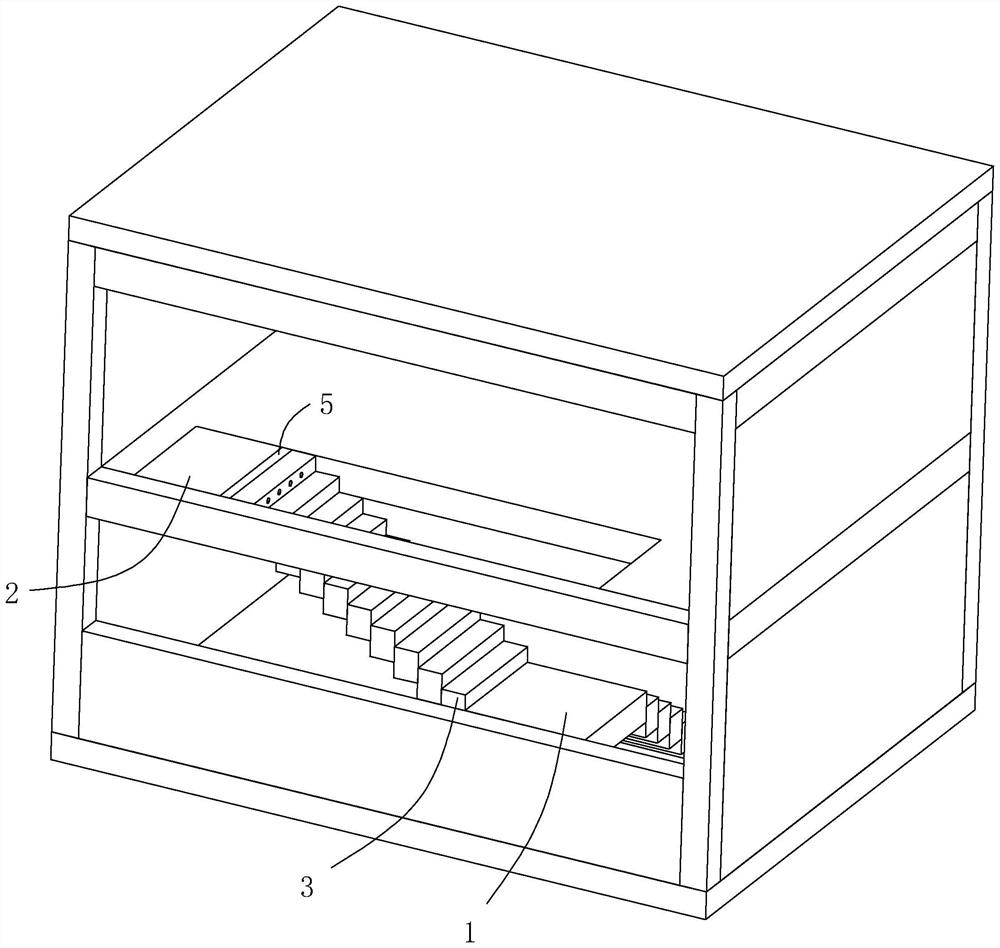

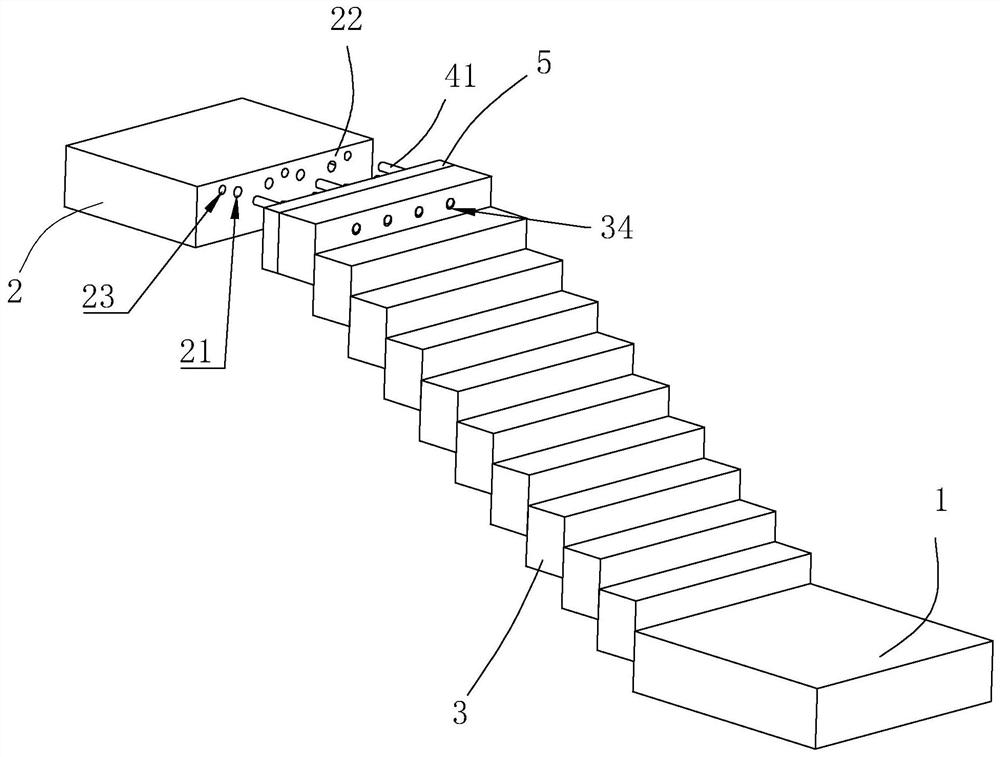

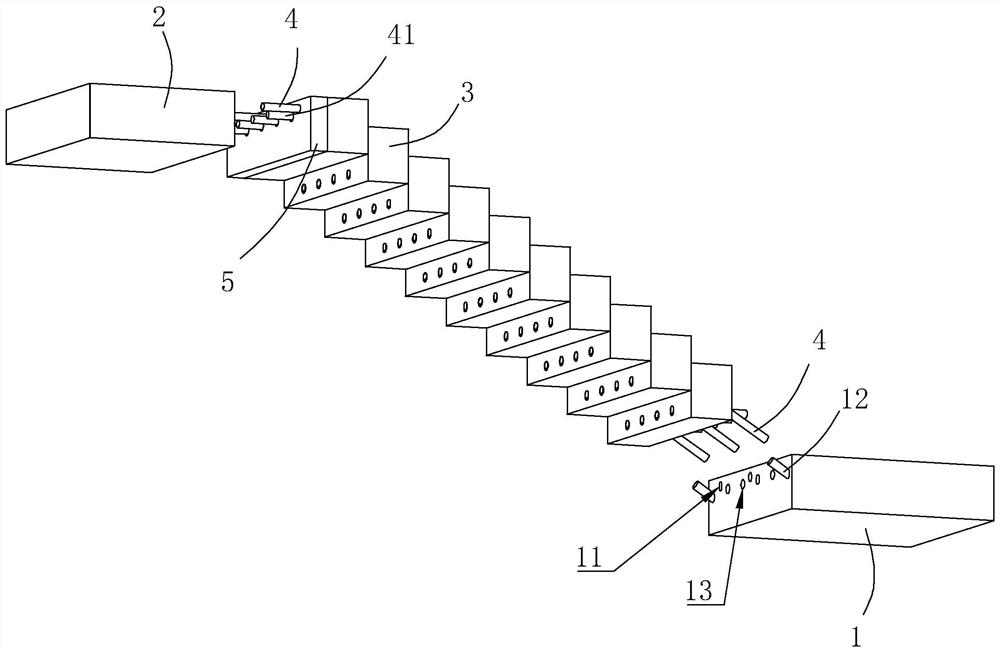

[0044] Such as Figure 1 to Figure 2 As shown, a prefabricated staircase for building construction disclosed by the present invention includes a support seat 1 and a positioning seat 2 fixed to a floor or a beam column, the positioning seat 2 is higher than the support seat 1, and the projection and support of the positioning seat 2 on the horizontal plane There are intervals between the projections of the seat 1 on the horizontal plane. A stair body is arranged between the support seat 1 and the positioning seat 2, the stair body includes several rectangular step units 3, and the upper end surfaces of the step units 3 are arranged horizontally. There is an equal height difference between the adjacent step monomers 3 , so that steps are formed between the adjacent step monomers 3 , wherein the upper end surface of the uppermost step monomer 3 is flush with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com