Hydraulic system control method and hydraulic system for compression garbage truck

A technology of a hydraulic system and a control method, applied in the field of sanitation special vehicles, can solve the problems of mutual restriction between efficiency improvement and operation noise, and achieve the effects of improving operation efficiency, eliminating impact and reducing operation noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

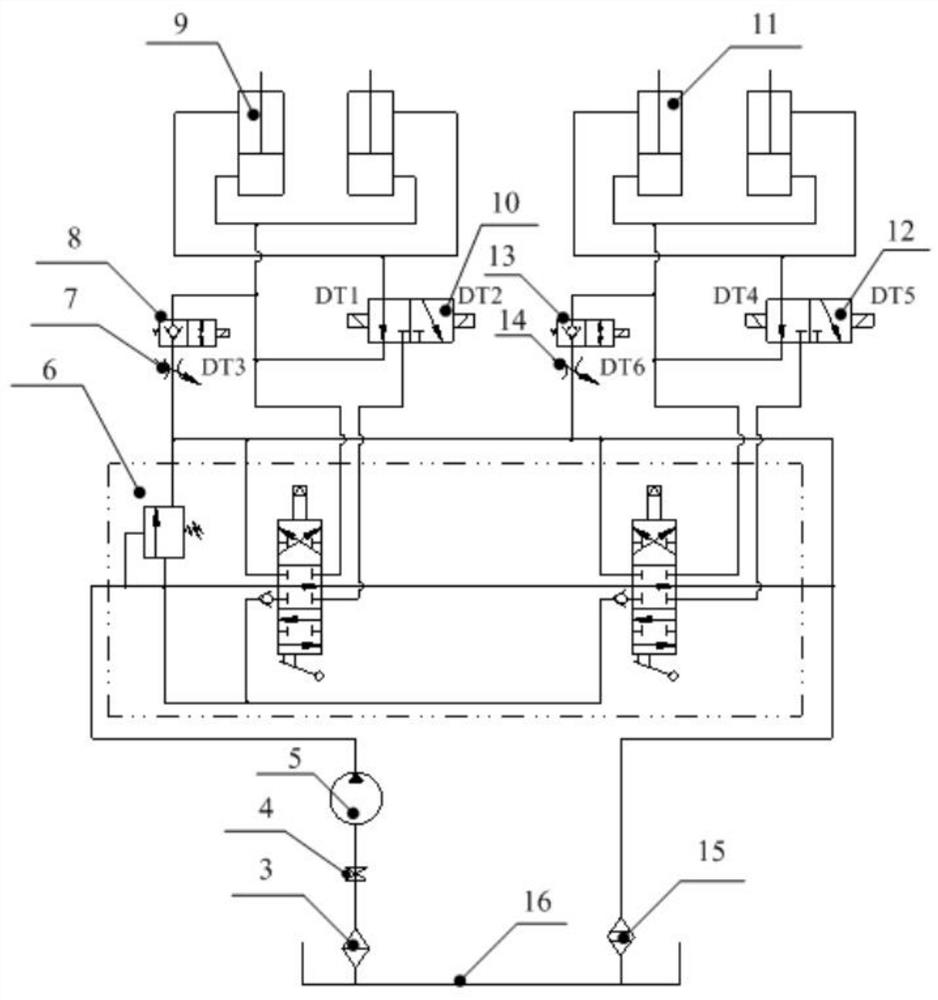

[0062] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

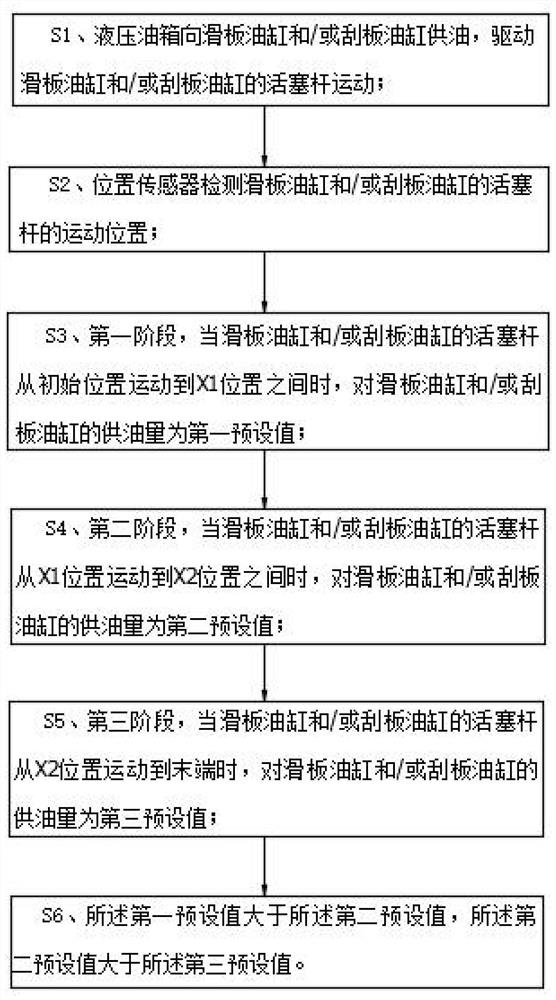

[0063] see figure 1 , the present embodiment is used for the hydraulic system control method of compression garbage truck, comprises the following steps:

[0064] S1. The hydraulic oil tank supplies oil to the slide cylinder and / or scraper cylinder, and drives the piston rod of the slide cylinder and / or scraper cylinder to move;

[0065] S2. The position sensor detects the movement position of the piston rod of the slide cylinder and / or the scraper cylinder;

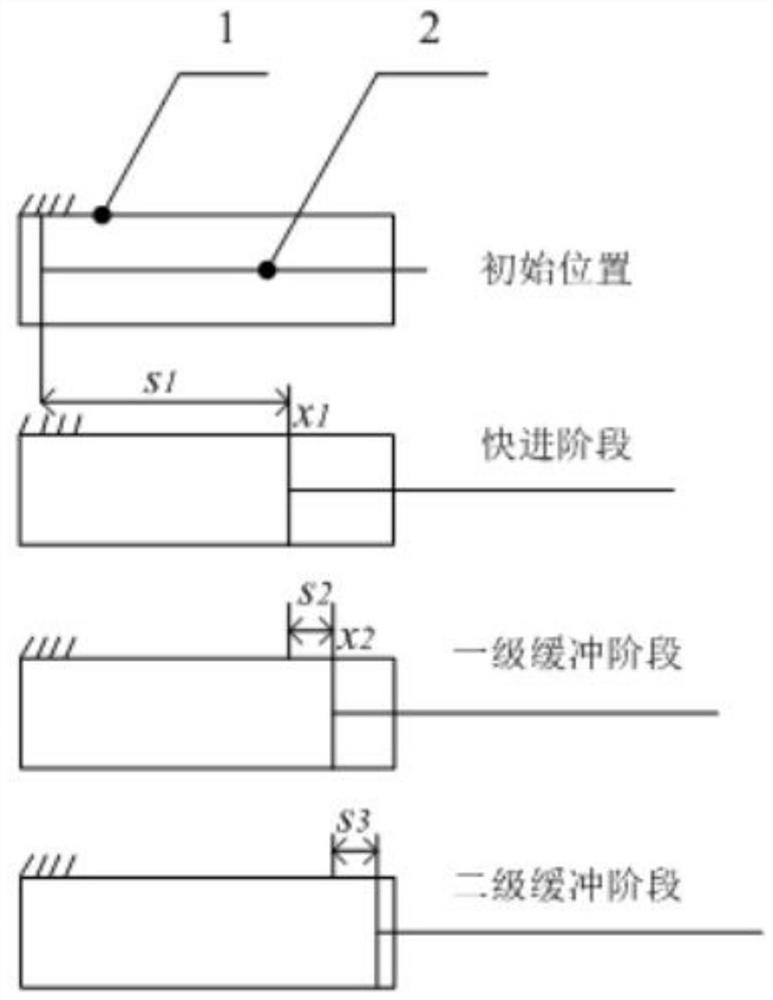

[0066] S3. In the first stage, when the piston rod of the slide cylinder and / or the scraper cylinder moves from the initial position to the X1 position, the amount of oil supplied to the slide cylinder and / or the scraper cylinder is the first preset value;

[0067] S4. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com