DC contactor

A DC contactor and electrical contact technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve problems such as unstable contact, large air pressure resistance, and stagnation, and achieve the effect of improving contact reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described in conjunction with the following examples.

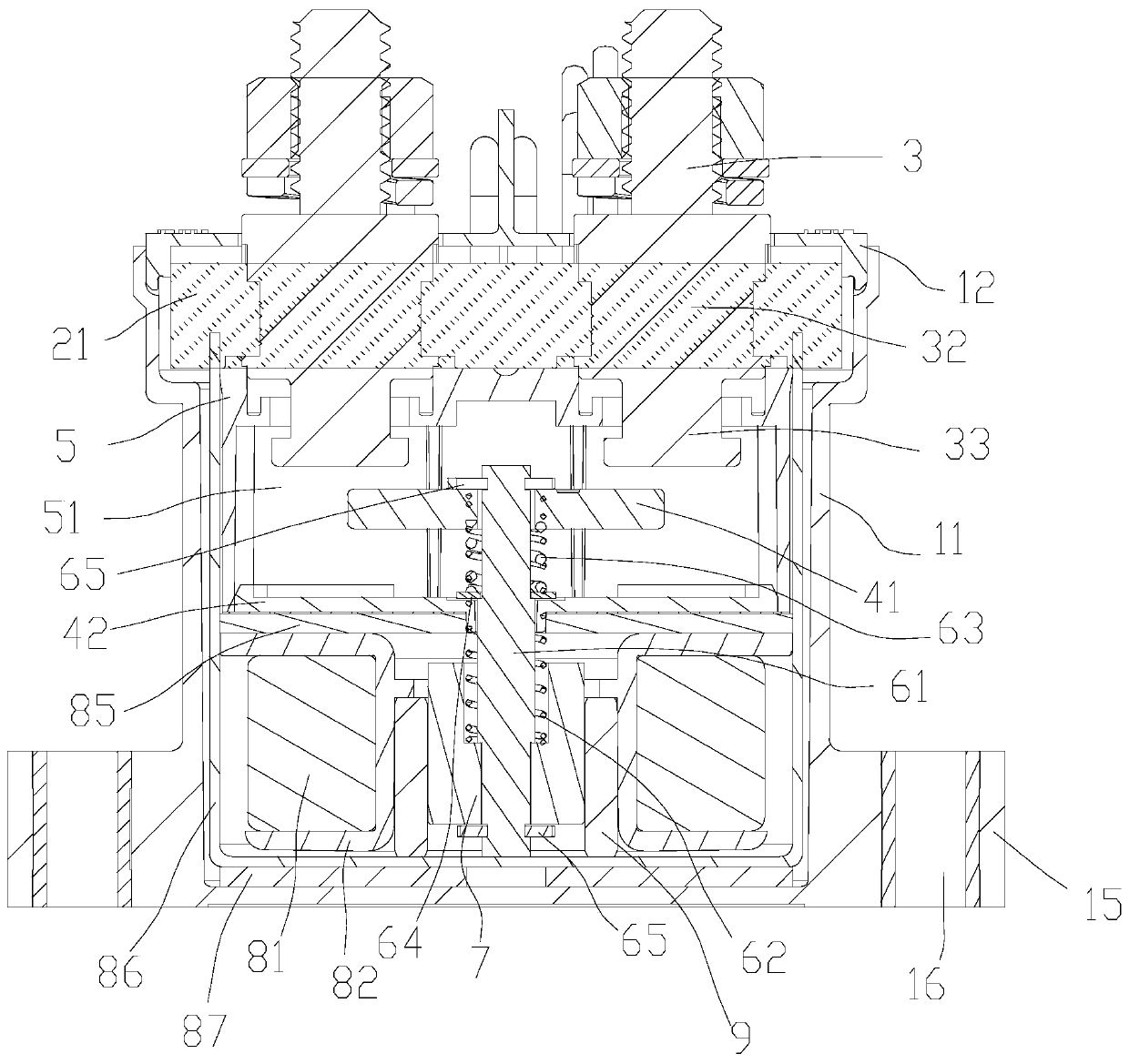

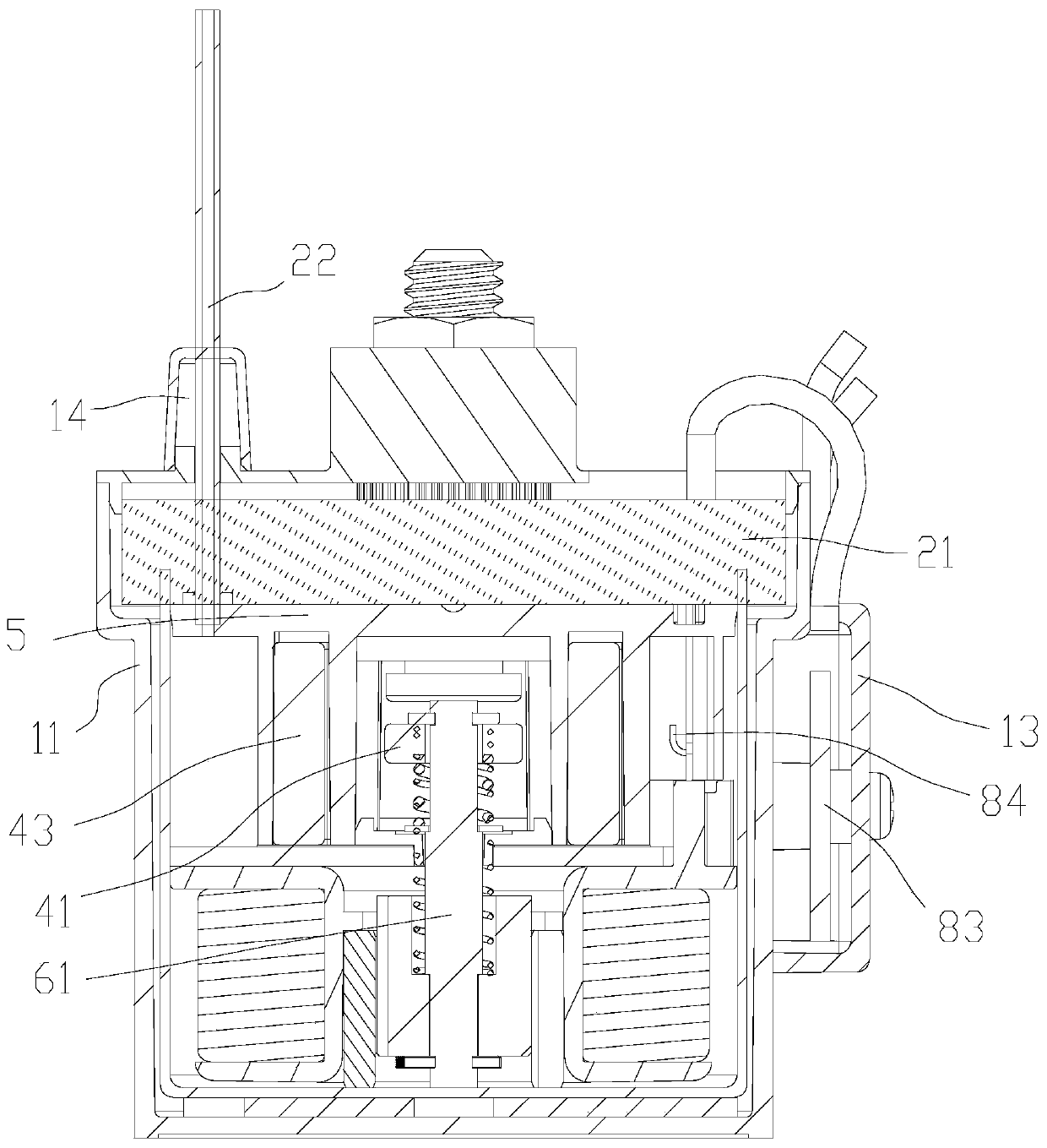

[0029] Depend on Figure 1 to Figure 7 It can be seen that a DC contactor described in this embodiment includes an insulating shell, a sealing member, an electrical contact member, a mechanical transmission member, and an electromagnetic drive member. Cover 12, a side cover 13 arranged on the side of the casing 11, and a notch shield 14 arranged on the top of the upper cover 12;

[0030] The sealing member includes glue 21 and an exhaust copper pipe 22 arranged on the scissor shield 14;

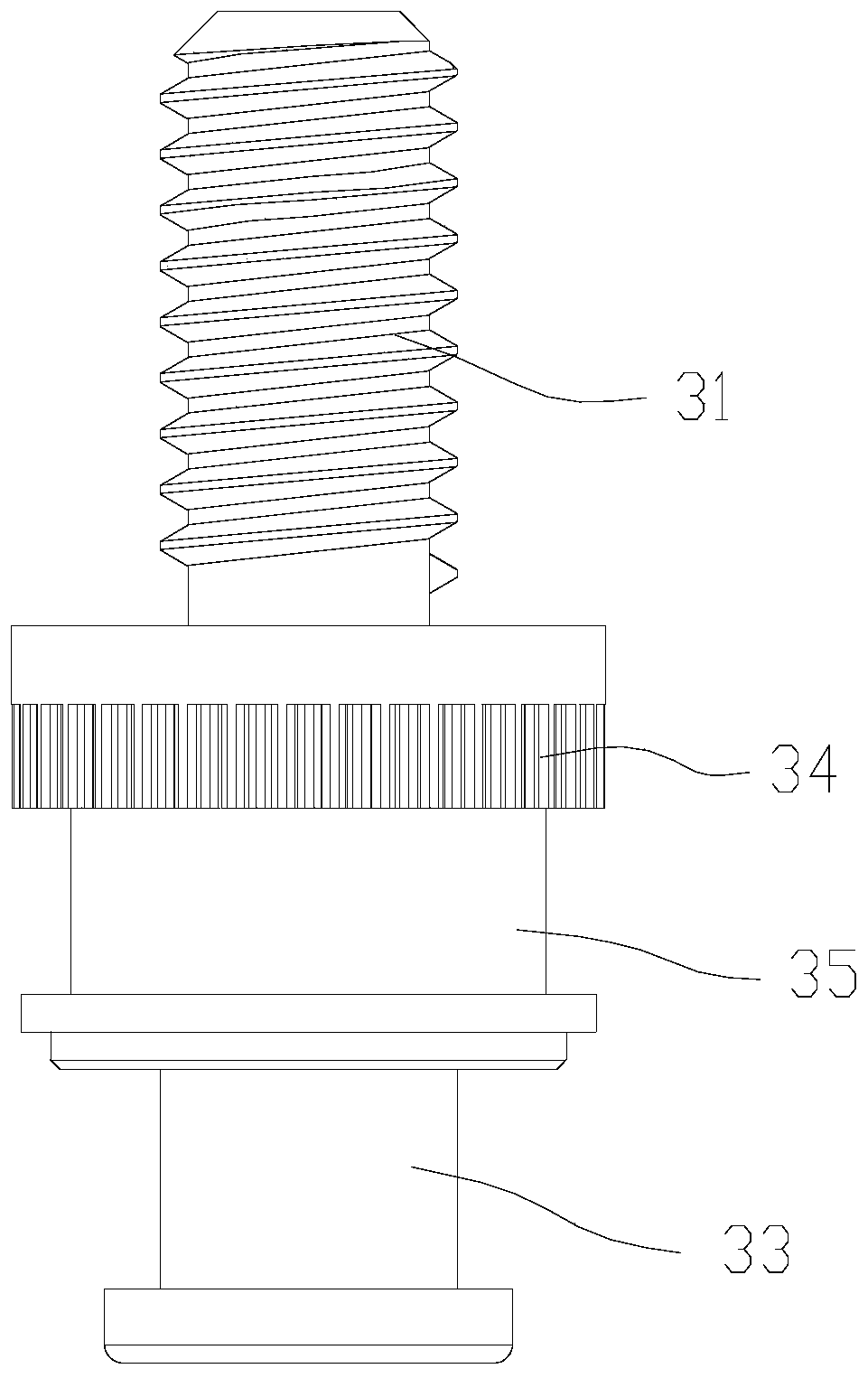

[0031] The electrical contact member includes a static contact 3, a moving bridge plate 41, an insulating cover 5, an insulating plate 42 and a magnet 43; the insulating cover 5 and the insulating plate 42 are all arranged in the housing 11; the insulating cover 5 and the An insulating cavity 51 is formed between the insulating plates 42; the static contact 3 protrudes into the insulating cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com