Rotor structure of a permanent magnet assisted bearingless synchronous reluctance motor

A technology of synchronous reluctance motor and rotor structure, applied in the direction of magnetic circuit shape/style/structure, synchronous machine, synchronous machine parts, etc., can solve the problems of large torque and suspension force pulsation, and achieve reduced torque and suspension Effect of force pulsation, reduced workload, and large degree of freedom of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

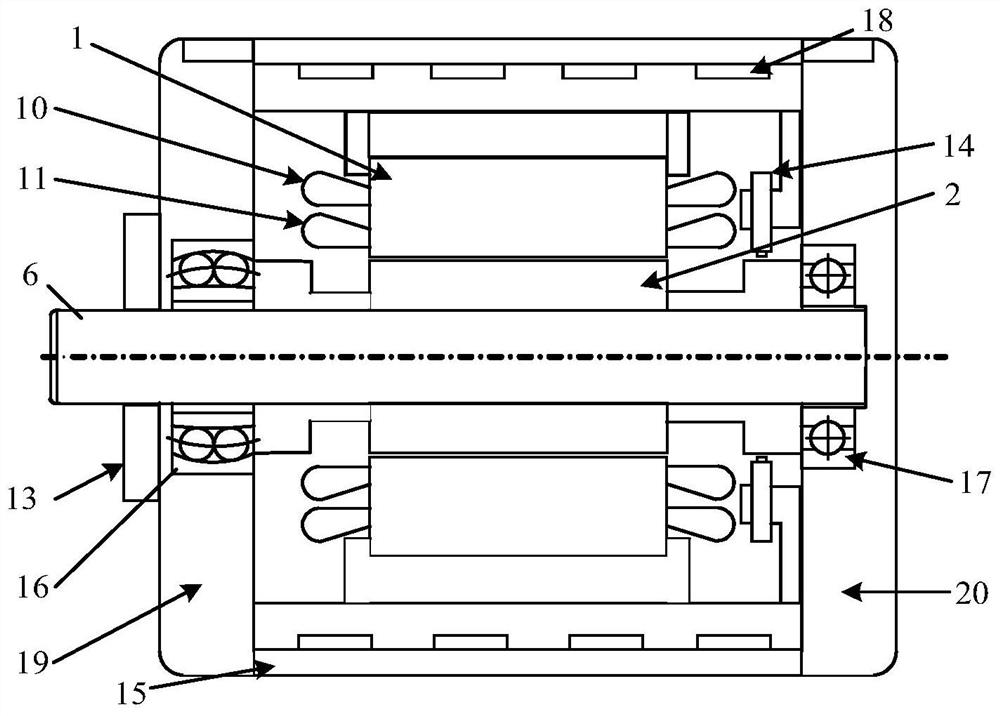

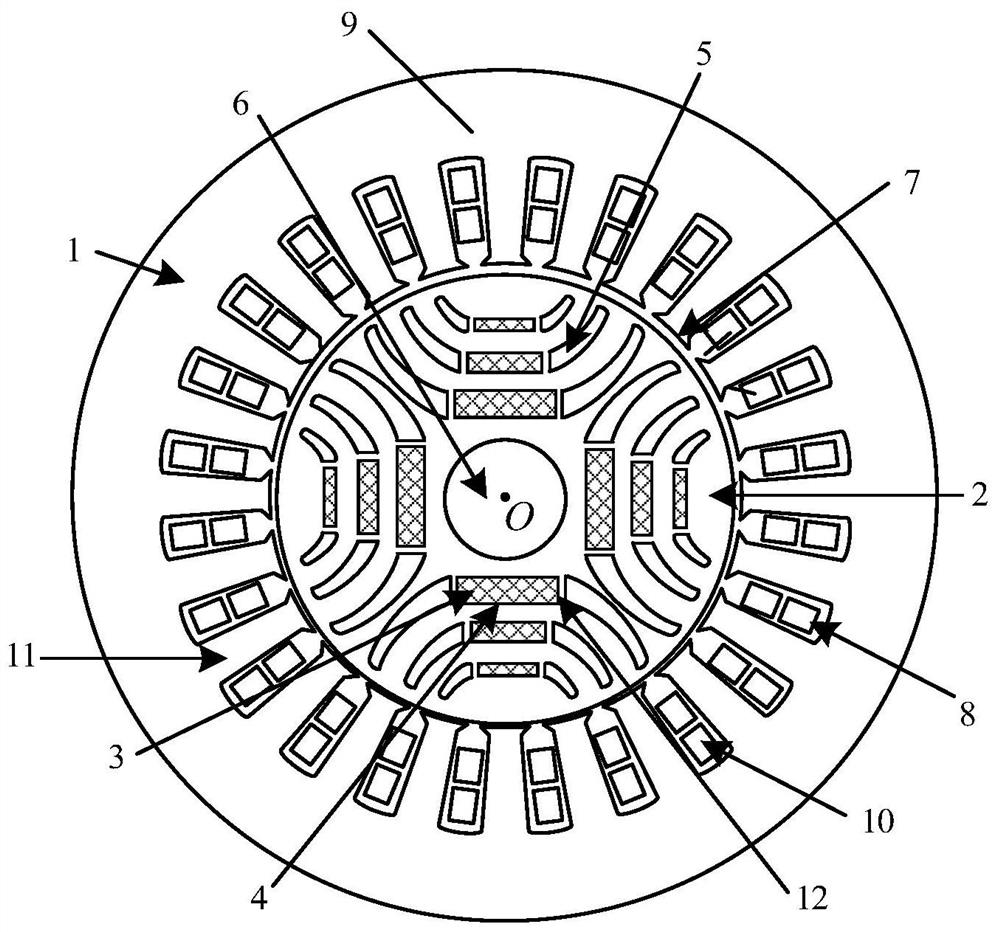

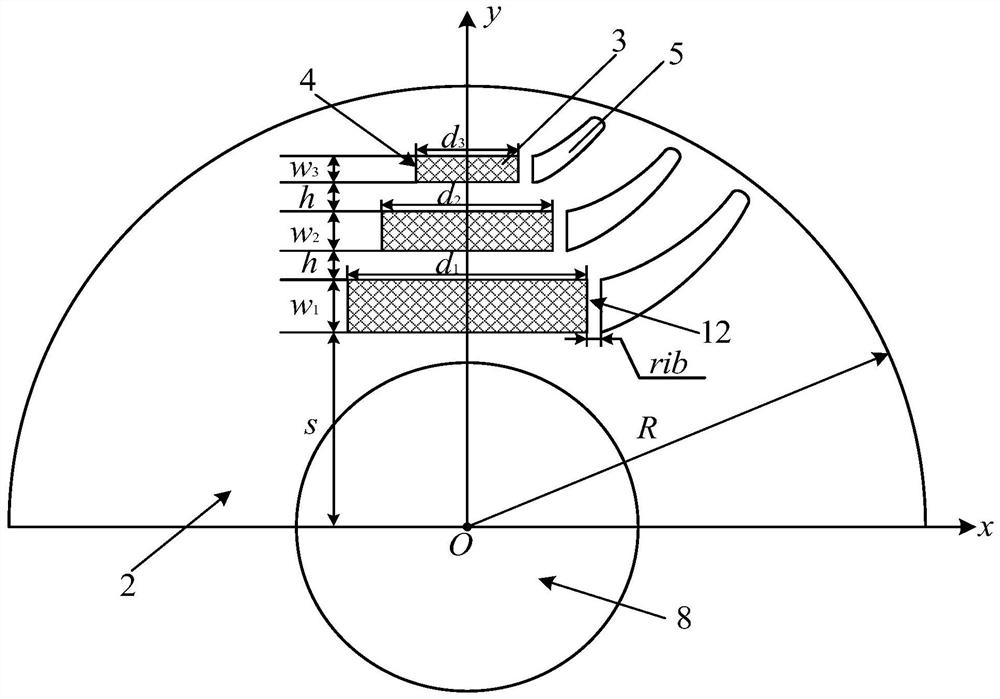

[0022] see figure 1 The permanent magnet assisted bearingless synchronous reluctance motor includes a stator 1, a rotor 2 and a rotating shaft 6. The rotor 2 is coaxially located inside the stator 1. The center of the rotor 2 is coaxially sleeved with a rotating shaft 6. A slot is opened in the center of the rotor 2 for placement. Spindle 6. The stator 1 has double-layer windings, the outer winding is the torque winding 10 , and the inner winding is the suspension force winding 11 . There is an air gap between the inner wall of the stator 1 and the outer wall of the rotor 2, and the thickness of the air gap is related to the power level of the motor, the selected permanent magnet material, and the processing and assembly process of the stator 1 and rotor 2. The casing 15 is used for fixing the stator 1 , the left end cover 19 and the right end cover 20 , the left end cover 19 is used for fixing the self-aligning ball bearing 14 , and the right end cover 20 is used for fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com