Roll cylinder turnover type steam enzyme deactivation machine for tea production

A technology of flipping and degreening machine, which is applied in tea treatment before extraction, etc. It can solve problems such as uneven heating, affecting tea quality, overheating, etc., and achieves the effect of improving stability and fast and uniform degreening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

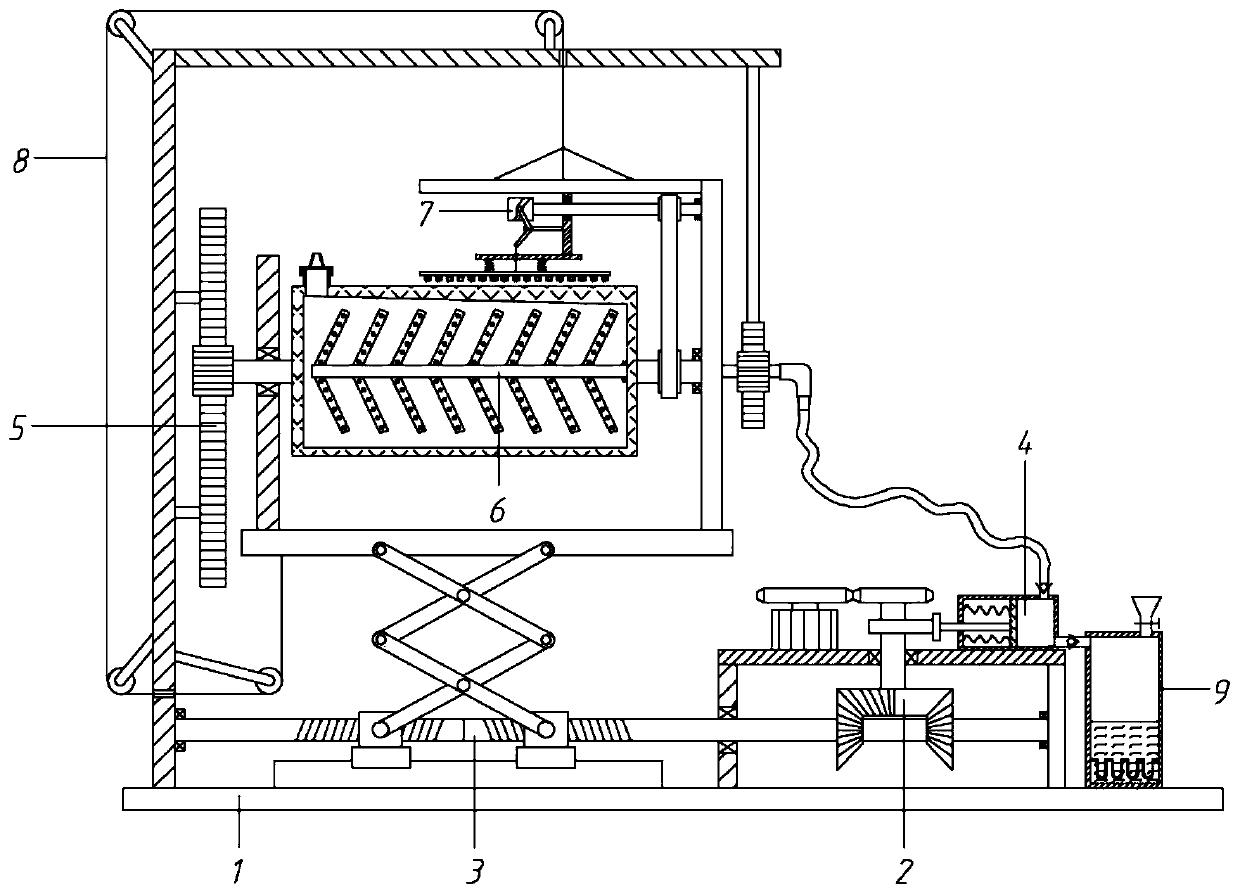

[0064] A drum turning type steam fixer for tea production, comprising a frame 1, a driving component 2, a SAIC component 4, a lifting component 3, a turning component 5 and a fixing component 6;

[0065] The frame 1 includes a base 101, a vertical plate 102 and a top plate 103. The left end of the base 101 is fixedly connected with the vertical plate 102, and the top of the vertical plate 102 is connected to the right with the top plate 103; the right part of the base 101 is provided with a drive assembly 2, and the left part is provided with a lifting assembly 3. The driving assembly 2 and the lifting assembly 3 cooperate; the right side of the driving assembly 2 is also equipped with a SAIC assembly 4; the lifting assembly 3 is provided with a turning assembly 5, and the turning assembly 5 is provided with a fixing assembly 6, and the fixing assembly 6 and the SAIC assembly 4 Cooperate.

Embodiment 2

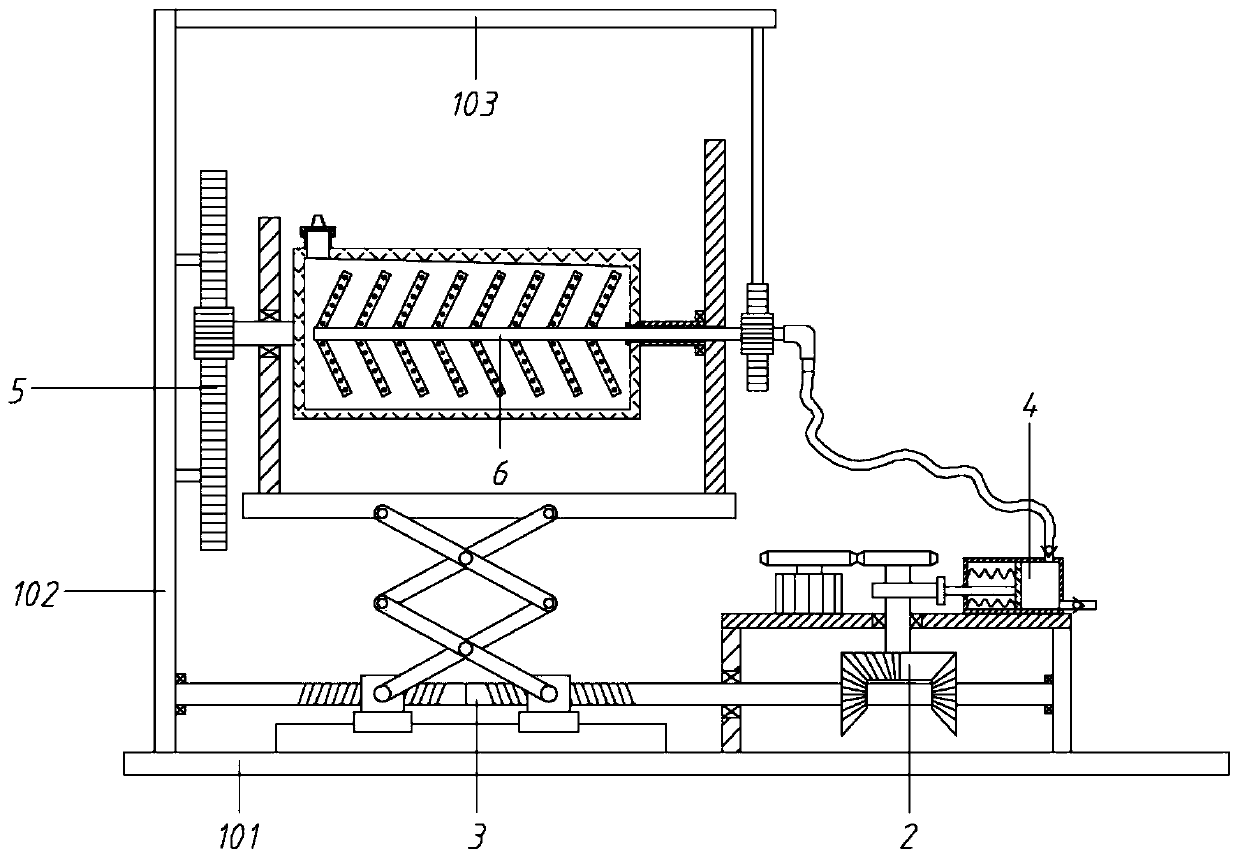

[0067] A drum turning type steam fixer for tea production, comprising a frame 1, a driving component 2, a SAIC component 4, a lifting component 3, a turning component 5 and a fixing component 6;

[0068] The frame 1 includes a base 101, a vertical plate 102 and a top plate 103. The left end of the base 101 is fixedly connected with the vertical plate 102, and the top of the vertical plate 102 is connected to the right with the top plate 103; the right part of the base 101 is provided with a drive assembly 2, and the left part is provided with a lifting assembly 3. The driving assembly 2 and the lifting assembly 3 cooperate; the right side of the driving assembly 2 is also equipped with a SAIC assembly 4; the lifting assembly 3 is provided with a turning assembly 5, and the turning assembly 5 is provided with a fixing assembly 6, and the fixing assembly 6 and the SAIC assembly 4 Cooperate.

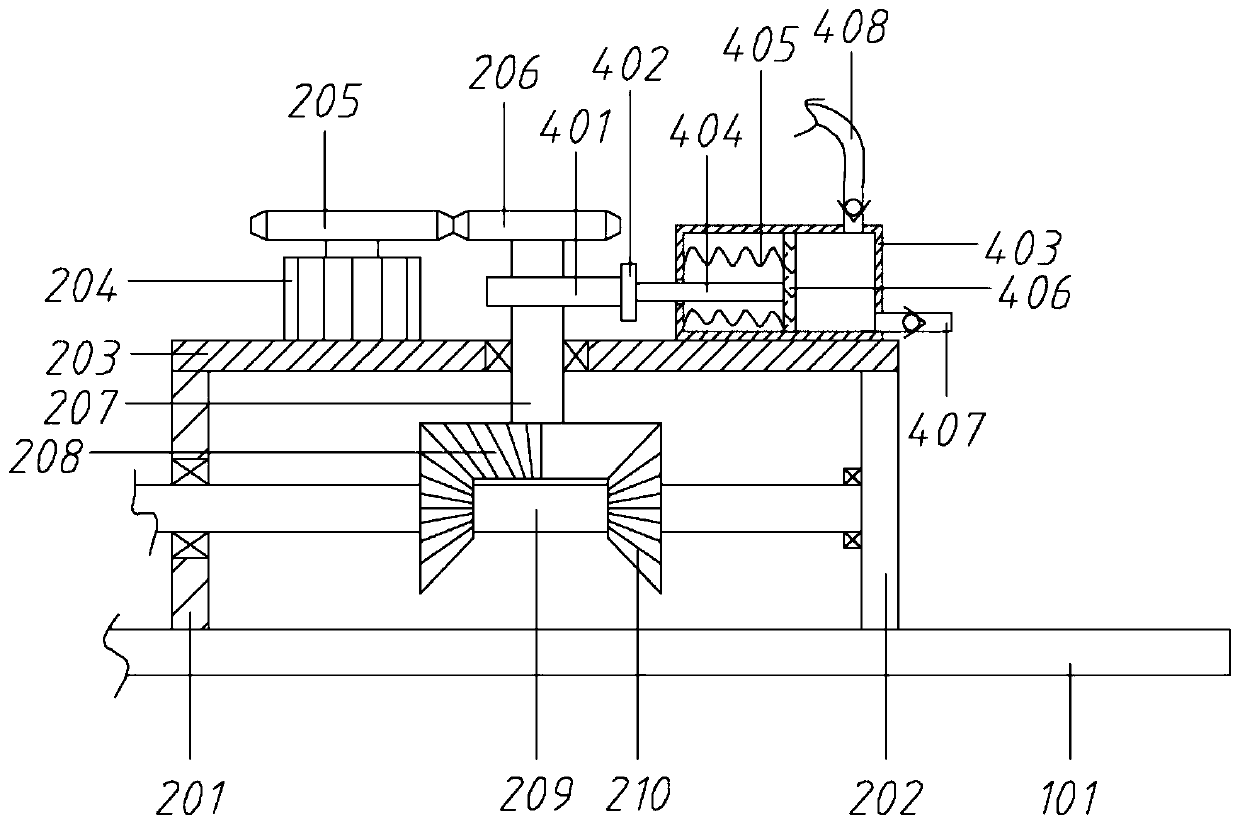

[0069] Wherein, the driving assembly 2 includes No. 1 plate 201, No. 2 plate 202, No. 3...

Embodiment 3

[0090] On the basis of embodiment 2,

[0091] Also includes the vibration material assembly 701; the vibration material assembly 701 includes the No. 1 drive wheel 701, the transmission belt 702, the No. 2 drive wheel 703, the No. 4 rotating shaft 704, the cylindrical cam 705, the No. 6 plate 706, the vertical plate 707, the transverse plate 708, Roller 709, bending rod 710, mounting rod 711, No. 1 stay rope 712, mounting plate 713, No. 2 spring 714 and pressure wheel 715;

[0092] The top of the fifth plate 502 is connected to the left with the sixth plate 706; the bottom surface of the sixth plate 706 is fixedly connected with a vertical plate 707, and the rotation between the vertical plate 707 and the fifth plate 502 is equipped with a fourth rotating shaft 704; No. 2 transmission wheel 703 is housed on the hollow shaft 509, and No. 1 transmission wheel 701 is housed on the hollow shaft 509. No. 1 transmission wheel 701 and No. 2 transmission wheel 703 are connected by tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com