Multifunctional efficient continuous cyclic extraction, modification and concentration equipment

A cyclic extraction, multi-functional technology, applied in solid solvent extraction, foam dispersion/prevention, evaporator accessories, etc., can solve the problems of poor material extraction efficiency, product cost increase, discarding, etc., to save usage and consumption, improve The effect of production efficiency and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0043] The technical solution of the present invention will be described in detail below with reference to the drawings and in combination with embodiments.

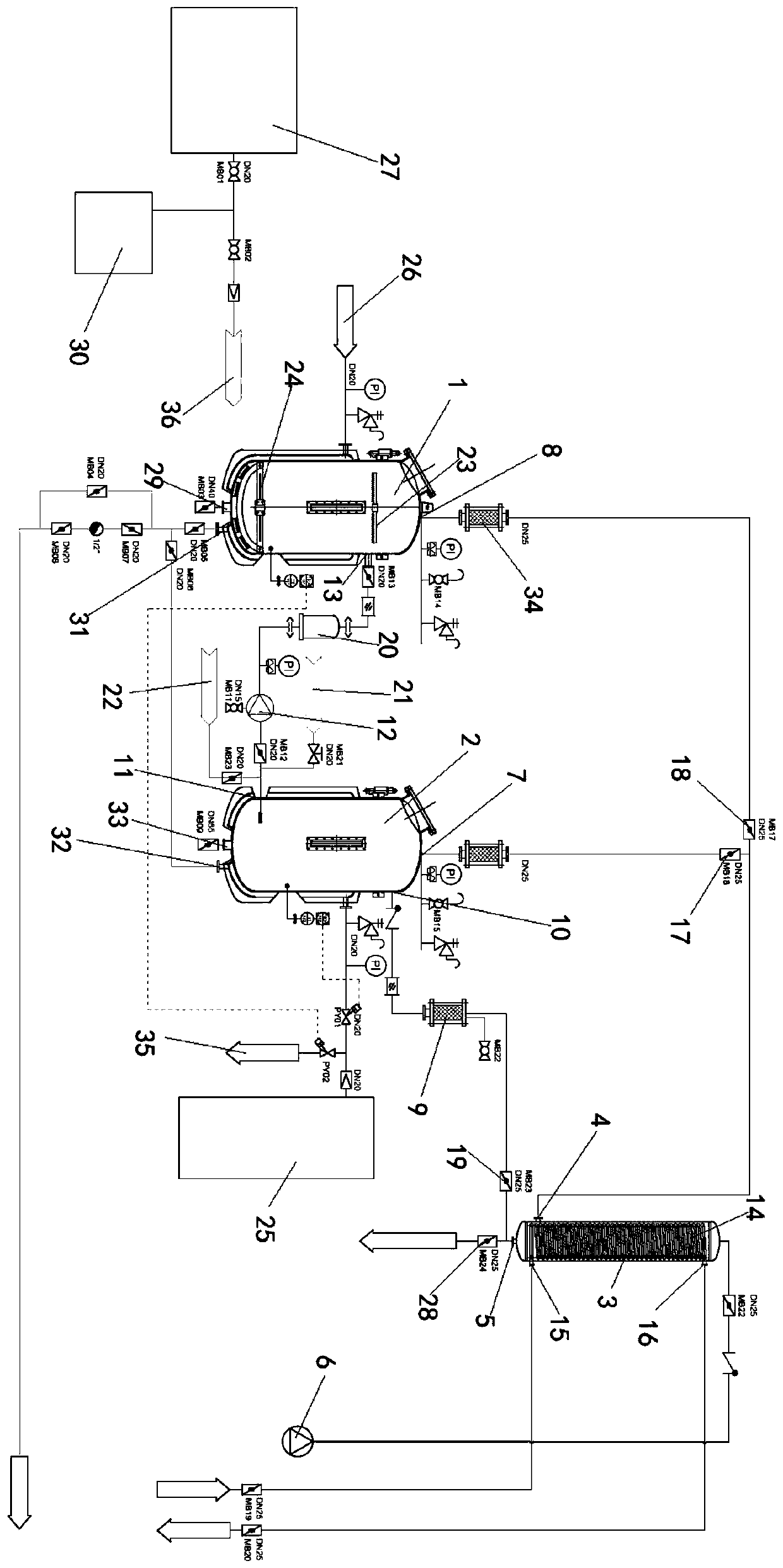

[0044] Such as figure 1 As shown, a multifunctional high-efficiency continuous circulation extraction modified concentration equipment, including evaporation and concentration tank 1, extraction tank 2, cooler 3;

[0045] The cooler 3 is vertically arranged, and includes an inner chamber, a first inlet 4 connected to the inner chamber and a first outlet 5, and the upper part of the inner chamber is connected with a vacuum pump 6; the first of the cooler 3 The inlet 4 is respectively connected to the first outlet 7 of the extraction tank 2 and the first outlet 8 of the evaporation and concentration tank 1, and the first outlet 5 of the cooler 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com