Raw material grinding device for magnet production

A technology of grinding device and raw materials, applied in the field of magnet production, can solve the problems of complex manufacturing structure, slow grinding speed and long time, and achieve the effects of simple structure, strong practicability and portable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

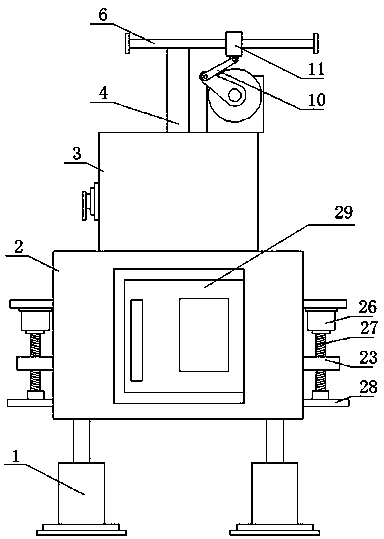

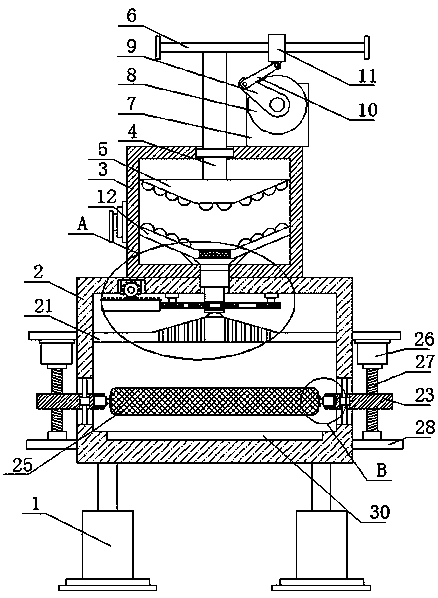

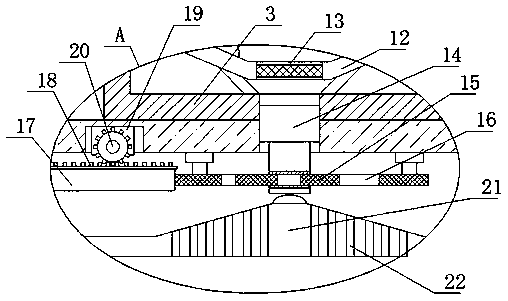

[0027] refer to Figure 1-6 , a raw material grinding device for magnet production, comprising two symmetrically arranged support bases 1, the same grinding box 2 is fixedly installed on the top of the two support bases 1, a crushing box 3 is fixedly installed on the top of the grinding box 2, and the crushing box The top of 3 is slidably connected to the pressing rod 4, the bottom of the pressing rod 4 extends into the crushing box 3 and the crushing block 5 is fixedly installed, and the top of the pressing rod 4 extends to the top of the crushing box 3 and is fixedly installed with a cross bar 6. The drive assembly is fixedly installed on the cross bar 6, the partition plate 12 is fixedly installed in the crushing box 3, and a through hole is opened in the middle position of the partition plate 12, and a matching screen 13 is fixedly installed in the through hole, The crushing box 3 and the grinding box 2 are provided with connected connecting holes, and a feeding pipe 14 is...

Embodiment 2

[0036] A raw material grinding device for magnet production, comprising two symmetrically arranged support bases 1, the same grinding box 2 is fixedly installed on the top of the two support bases 1, a crushing box 3 is fixedly installed on the top of the grinding box 2, and the crushing box 3 The top of the push rod 4 is slidingly connected with the pressing rod 4, the bottom of the pressing rod 4 extends into the crushing box 3 and the crushing block 5 is fixedly installed, and the top of the pressing rod 4 extends above the crushing box 3 and the cross bar 6 is fixedly installed , the drive assembly is fixedly installed on the cross bar 6, and the drive assembly will drive the crushing block 5 to reciprocate longitudinally, so the magnet raw material in the crushing box 2 can be crushed by using the crushing block 5, and a partition 12 is fixedly installed in the crushing box 3 , a through hole is provided at the middle position on the partition plate 12, and a matching scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com