Welding equipment for side-end steel plates and stacked welding method thereof

A welding equipment and welding method technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of insufficient accuracy, inconvenient manual operation, lack of automation equipment, etc., to solve the problem of low work efficiency and guarantee Accuracy to ensure one-to-one correspondence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

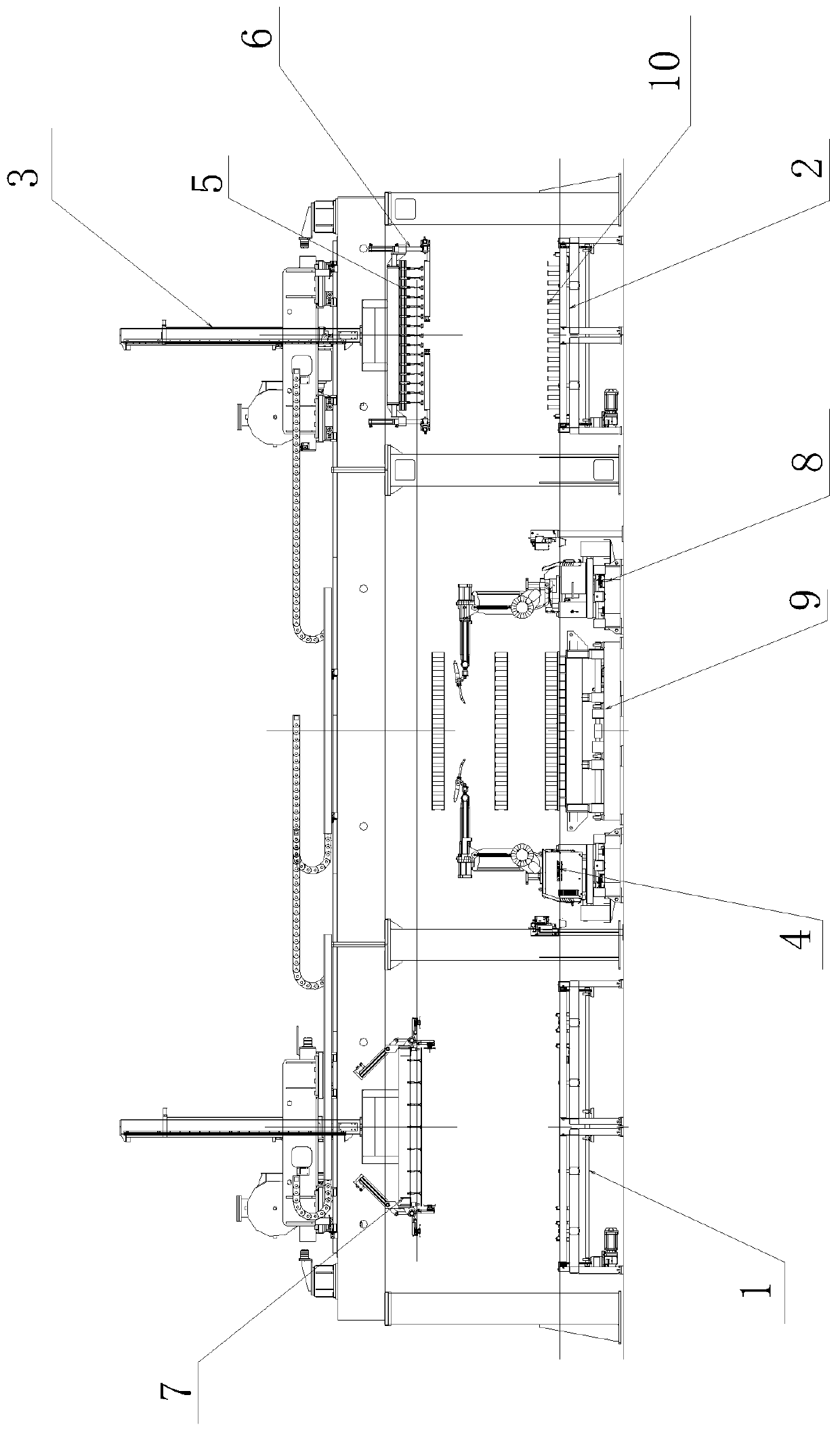

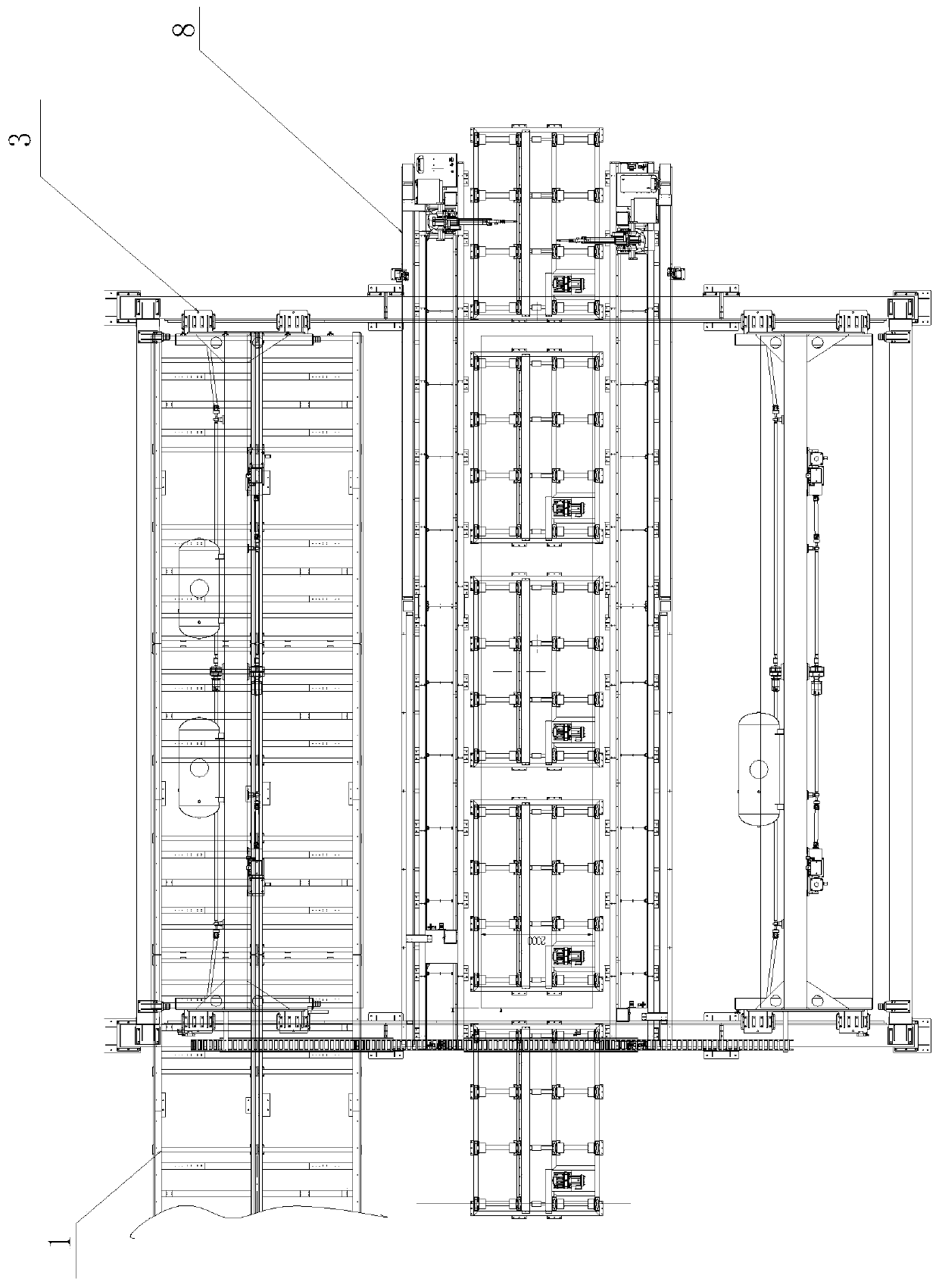

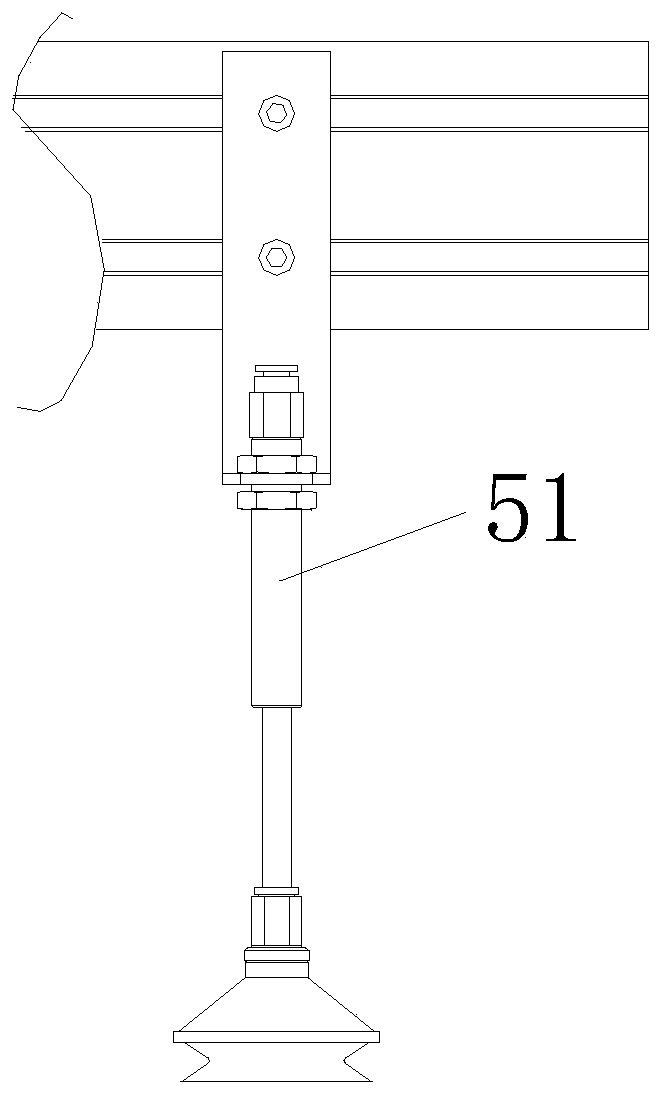

[0024] Such as Figure 1 to Figure 5 As shown, a welding equipment for side-end steel plates includes a top plate side plate conveying line for conveying the top plate and side plates 1, a core plate bottom plate conveying line for conveying core plates, and several groups of grippers for grabbing materials. The material manipulator 3 and the arc welding robot 4 for spot welding also include a core plate gripper 5 for grabbing the core plate and a top plate side plate grabbing device respectively arranged on the material grabbing manipulator 3 Tool 7. A fall prevention mechanism 6 arranged on the core board gripper 5 for placing the core board to fall.

[0025] The lower end of the welding station between the arc welding robots 4 is provided with a rolling bed 9 for quick replacement of welding ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap