Automatic polishing production line for aluminum alloy profile

A technology for aluminum alloy profiles and production lines, which is applied in the directions of grinding machines, grinding feed motions, grinding workpiece supports, etc., can solve the problems of long auxiliary time, high labor intensity, troublesome clamping, etc., and achieves beautiful appearance and good surface quality. , good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

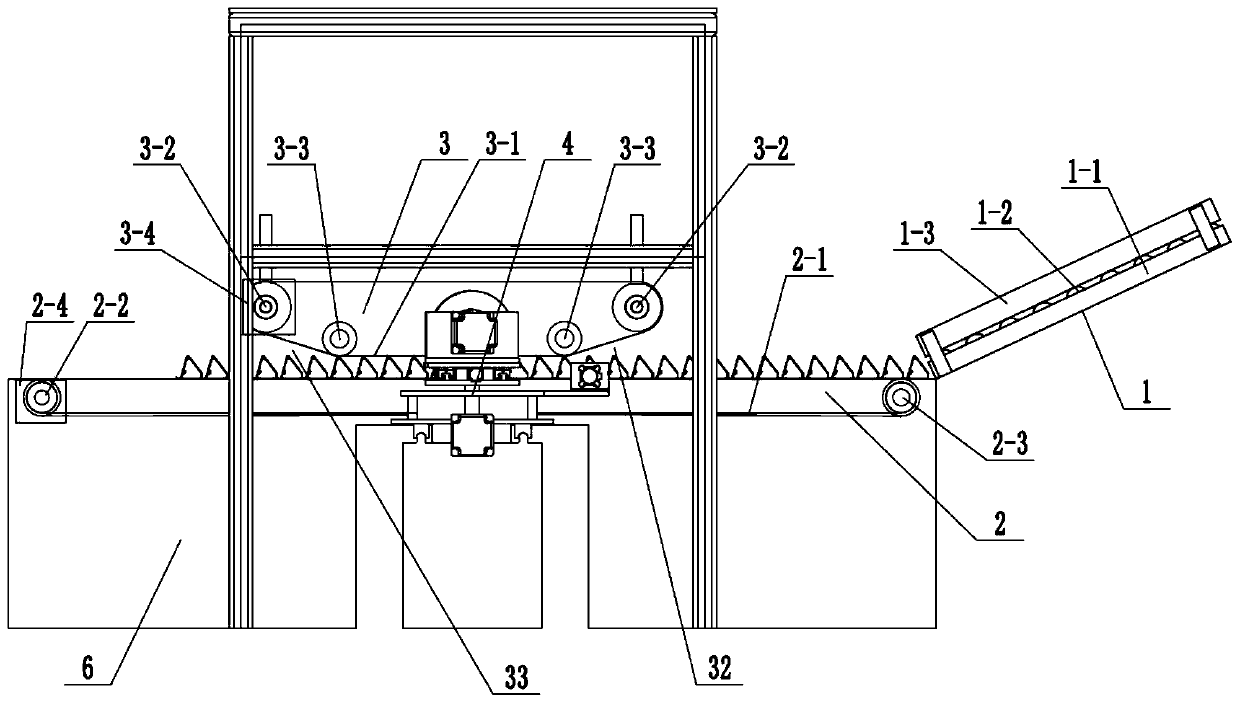

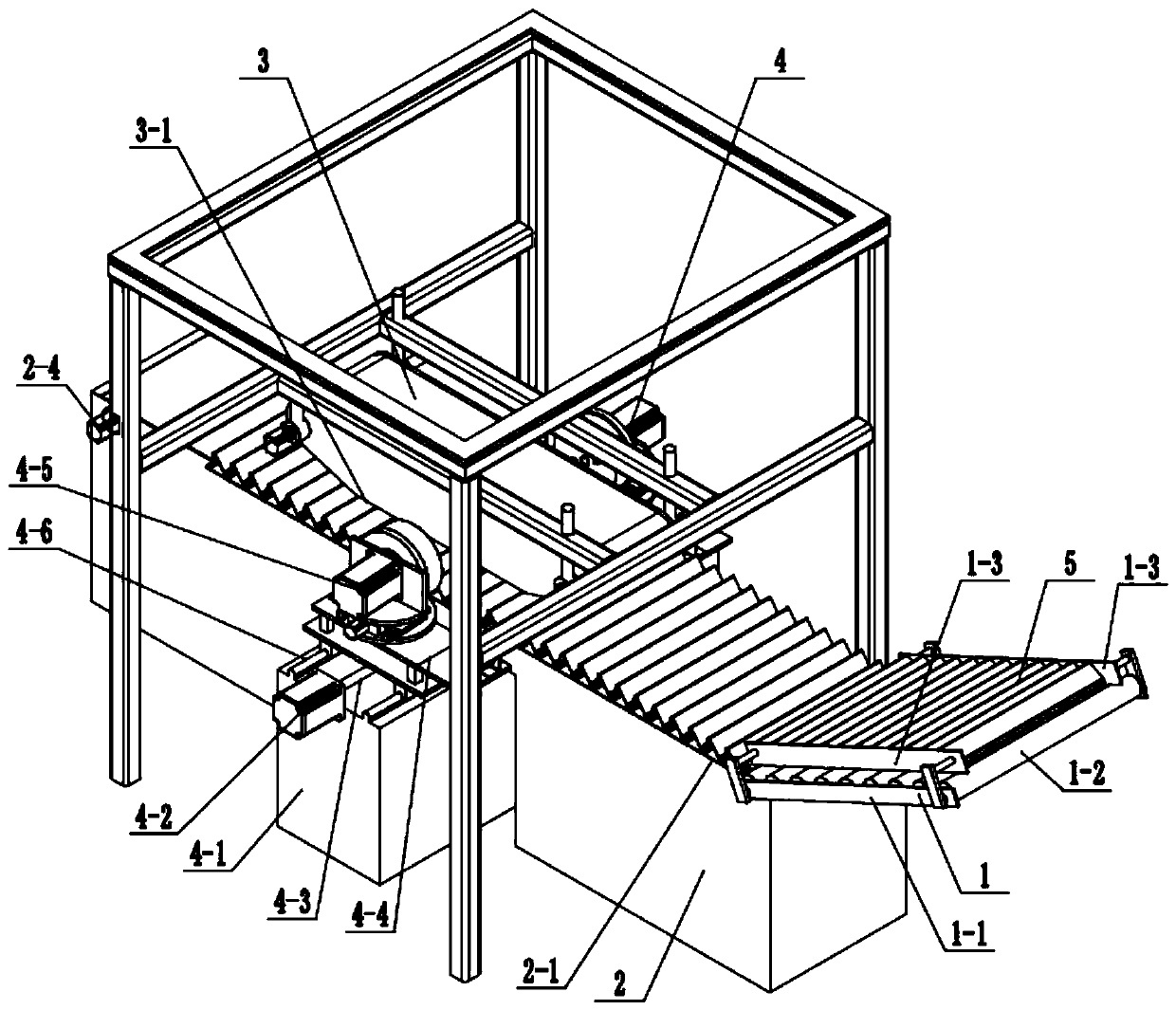

[0034] Example: see Figure 1-8 , an automatic grinding production line for aluminum alloy profiles, which includes a feeding mechanism 1, a first belt transportation mechanism 2, a second belt transportation mechanism 3 and a grinding mechanism 4.

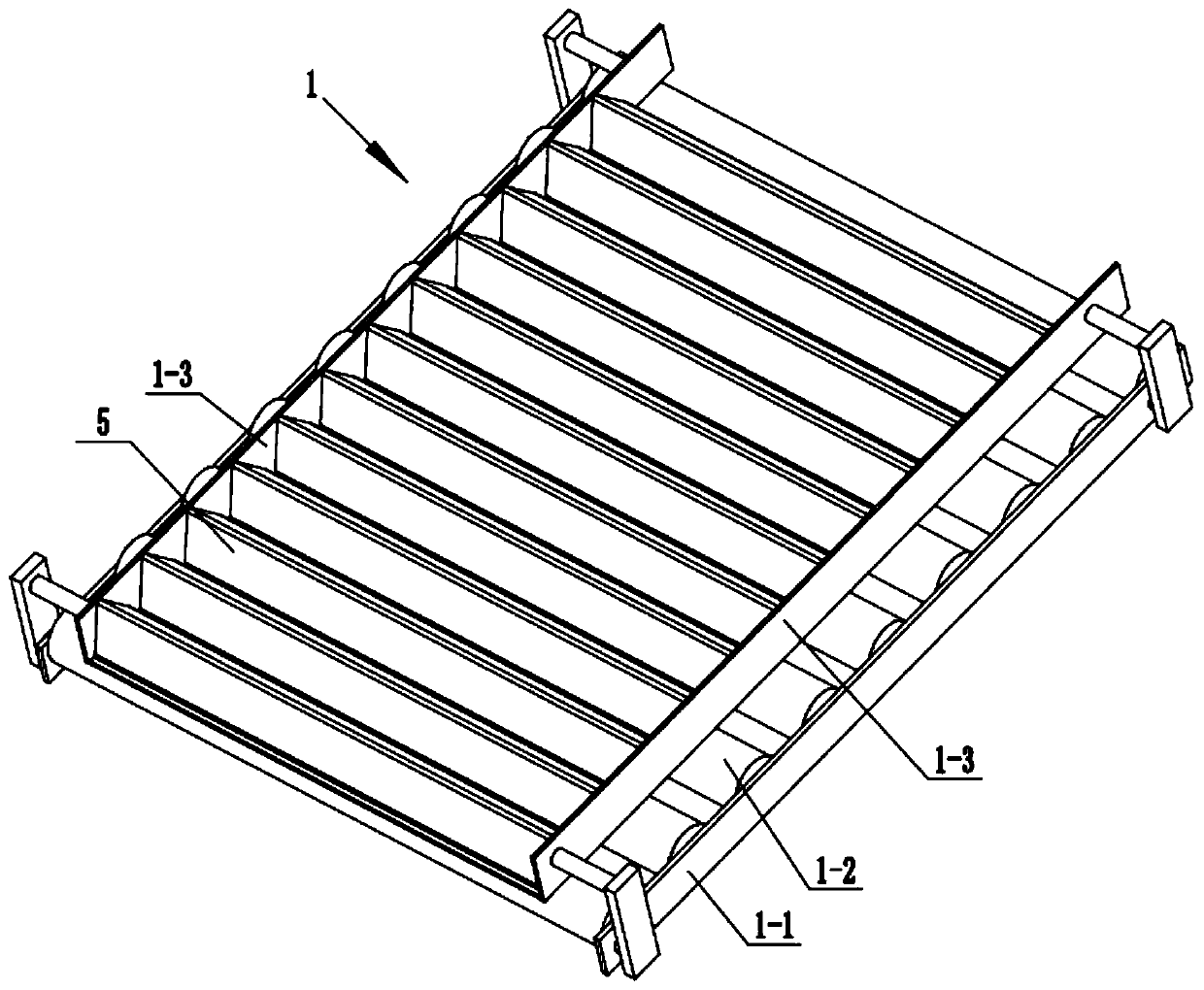

[0035] see Figure 1-3 , wherein, the feeding mechanism 1 includes a feeding bracket 1-1, a plurality of rollers 1-2 and two guide plates 1-3, each roller 1-2 is arranged side by side along the inclined direction at intervals, and each roller 1-2 2 is rotatably installed on the feeding bracket 1-1, the two guide plates 1-3 are respectively located on both axial sides of the roller shaft 1-2 and the gap width between the two guide plates 1-3 is the same as The lengths of the aluminum alloy profiles 5 to be processed match.

[0036] see Figure 1-2 and 4, the first belt transport mechanism 2 includes a first conveyor belt 2-1 and a first driving assembly for driving the first conveyor belt 2-1 to feed in the horizontal direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com