Paper die cutting method for forming any arc on packaging box

A packaging box and paper technology, which is applied in the field of packaging box production, can solve the problems of inaccurate arc alignment, slow machine speed, difficult arc, etc., and achieve the effect of avoiding roughening and reducing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

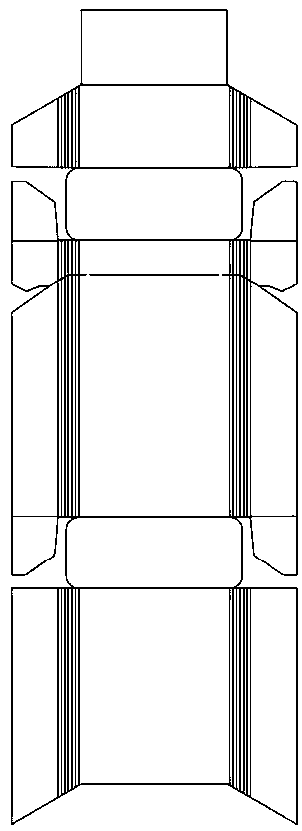

[0018] like figure 1 As shown, the paper die-cutting method for forming any arc on the packaging box of the present invention divides the knife line equally according to the size of the arc circle formed on the packaging box. When the die-cut boards are joined together, the gaps formed between the blades are smaller.

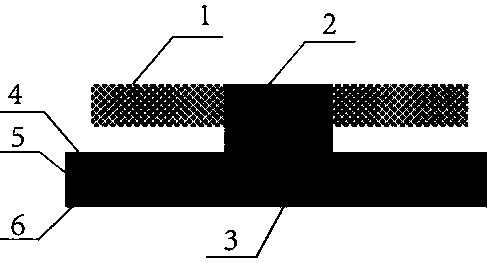

[0019] like Figure 2a-2c As shown, cigarette paper is generally divided into a three-layer structure of surface fiber 4, core layer fiber 5, and bottom layer fiber 6. When the die-cutting knife is die-cutting, the paper is half-cut, and the knife cuts the surface layer fiber 4 and the core layer fiber 5. At the same time, the gap between the knives Compress the thickness of the surface fiber and the core fiber to make the core fiber 5 and the surface fiber 4 of the paper plastically deformed. When the cigarette pack is formed, the paper can be formed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com