Train wheel tread defect and out-of-roundness three-dimensional image pass-type detection system

A technology of train wheels and three-dimensional images is applied in the field of systems for accurately detecting wheel out-of-roundness and tread defects, and can solve the problem of inability to detect out-of-roundness and tread defects, inability to automatically alarm, automatic alarm, false alarm rate, depth information image Analysis of problems such as increasing difficulty, to achieve the effect of being conducive to sharing and analysis, convenient data cloud storage, and high degree of informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

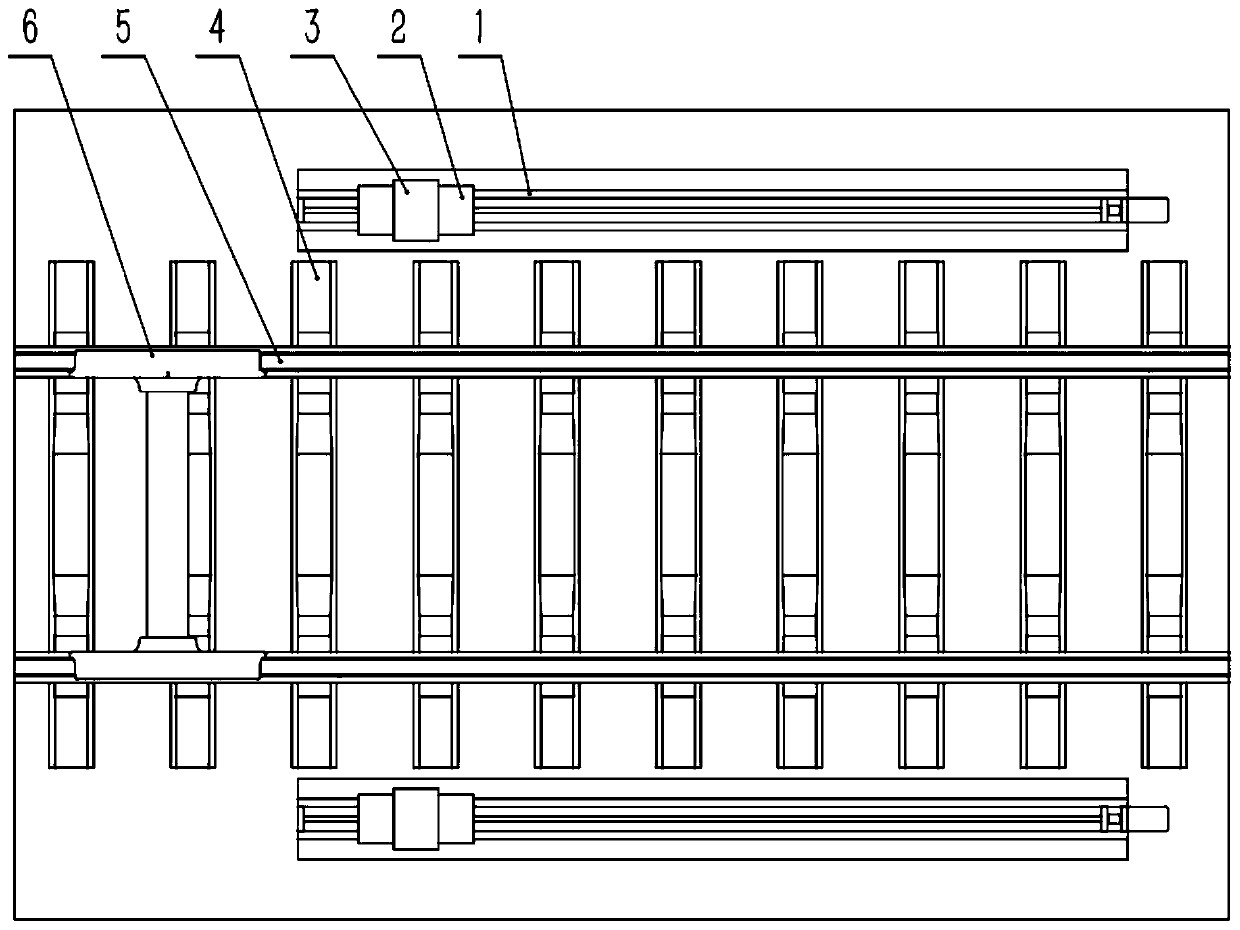

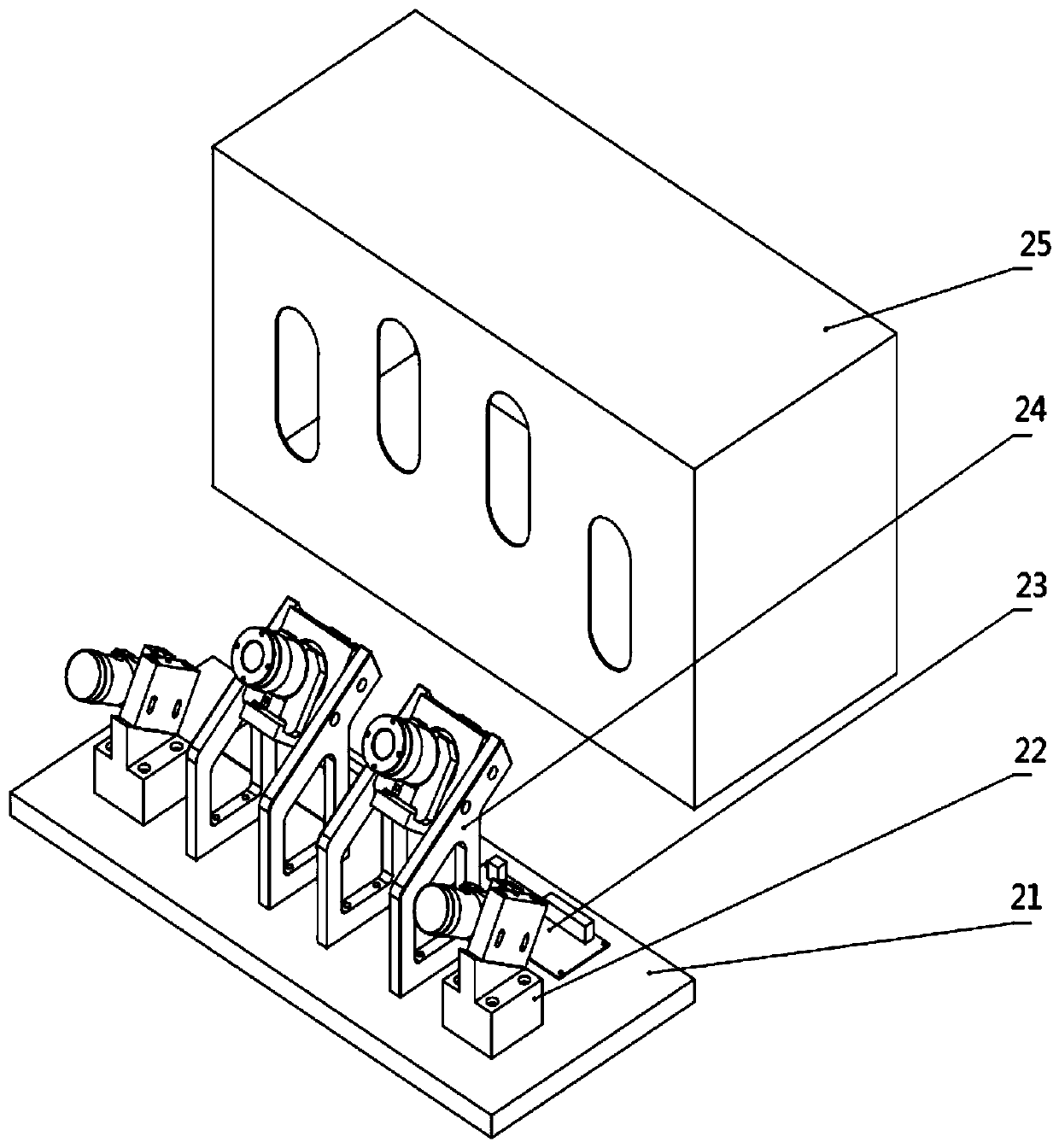

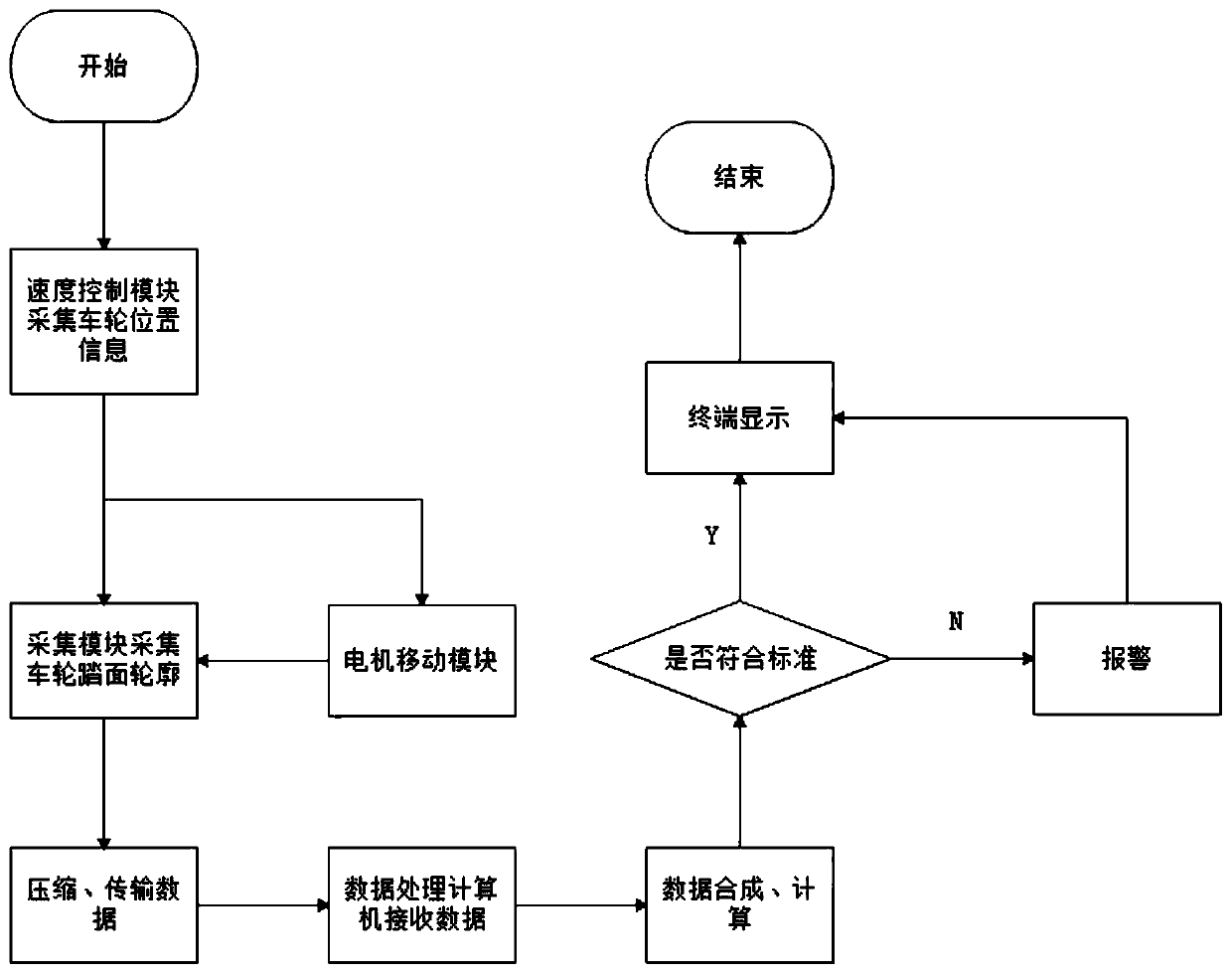

[0023] Such as figure 1 As shown, the on-site layout diagram of the detection system of the present invention, the detection system includes an acquisition module, a speed measurement control module, a motor movement module and a data processing module, the motor movement module is fixed on the track beds on both sides of the track, the acquisition module and the speed measurement The control module is installed on the motor moving module; the detection system of this embodiment is installed at the throat of the train entering the warehouse, and the out-of-roundness of the wheel and the size of the tread defect can be detected by the train passing through the detection once.

[0024] The collection module collects the wheel tread profile a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com