Disk rotating type plate cutting and storing device

A storage device and a rotating technology, which can be used in decorative arts, transportation and packaging, conveyors, etc., can solve difficult plate processing and other problems, achieve high processing efficiency, better dust removal effect, and avoid cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

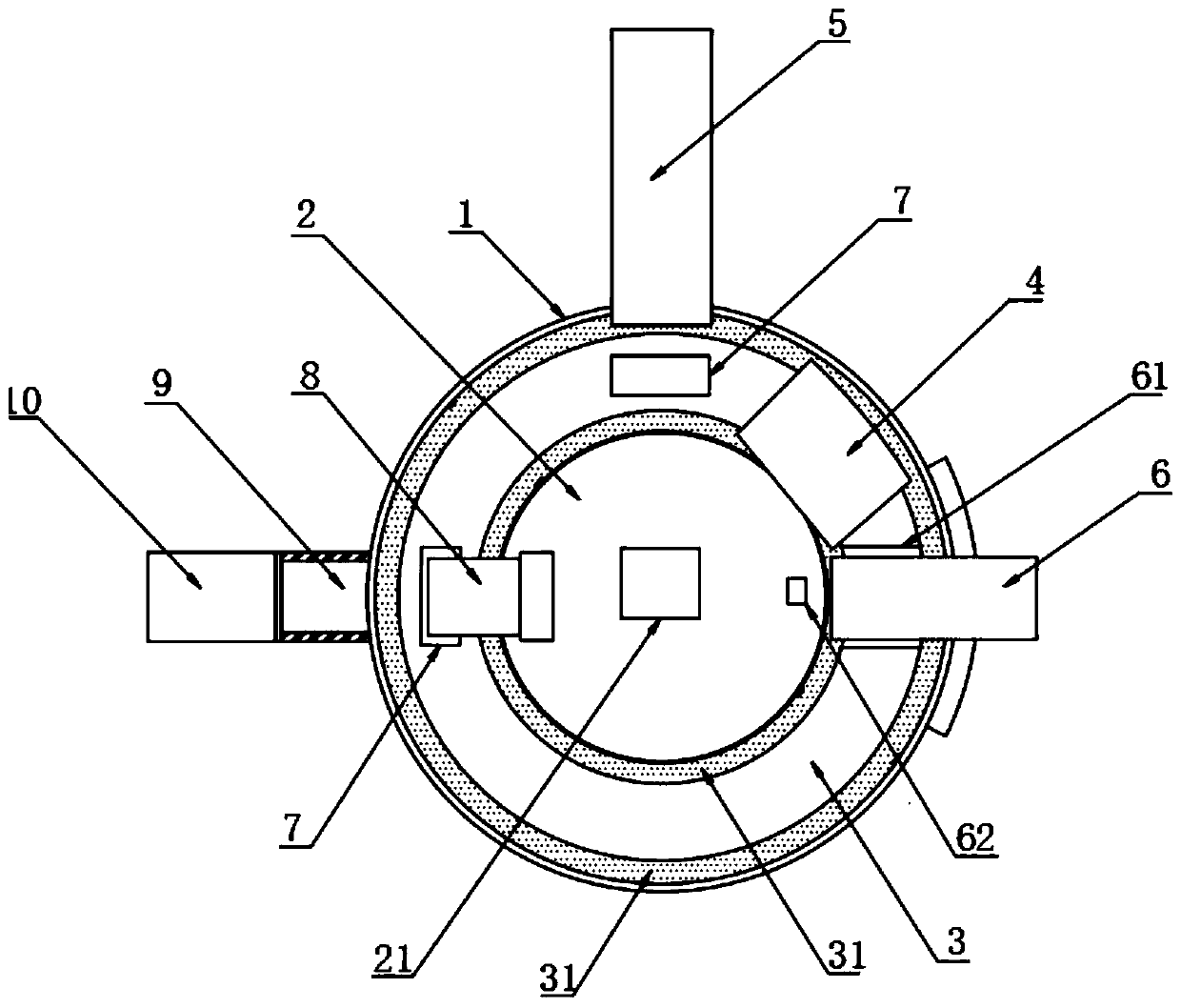

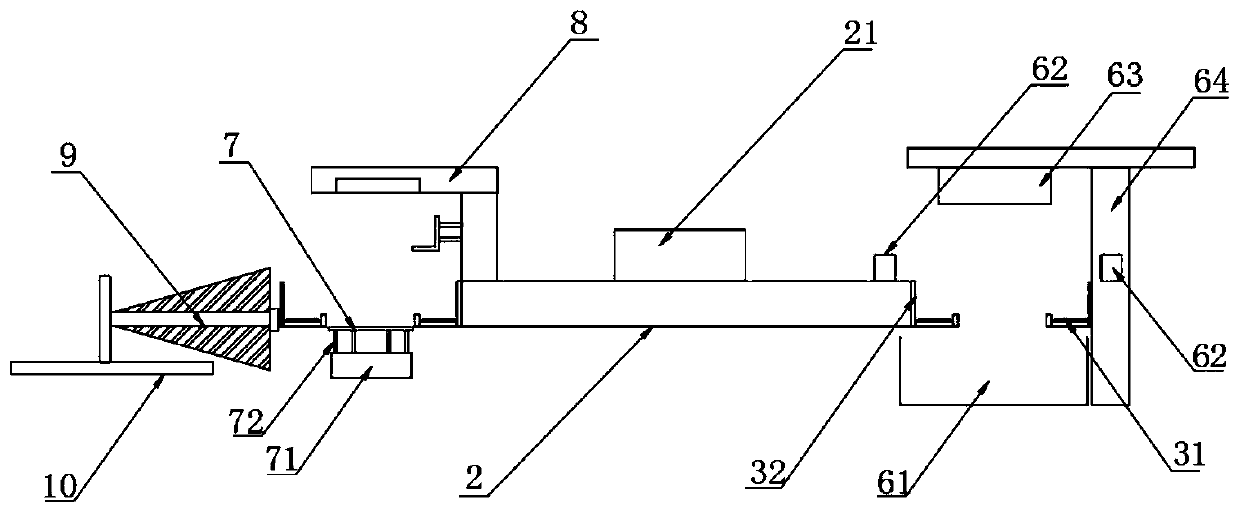

[0034] The surface of the fixed plate 2 is provided with a control mechanism 21, the control mechanism 21 includes a control unit, a PLC controller and a storage battery pack, two conveyor belts 31 are respectively arranged on the inner wall of the main body plate 1 and the outer wall of the fixed plate 2, and the conveyor belts There are limit plates 32 on both sides of 31, and the PLC controller model is set to FX1S. The working time and control interval of the equipment are set by the control mechanism 21, and the corresponding equipment can be controlled to work at different times to realize the cycle processing of the entire equipment. process.

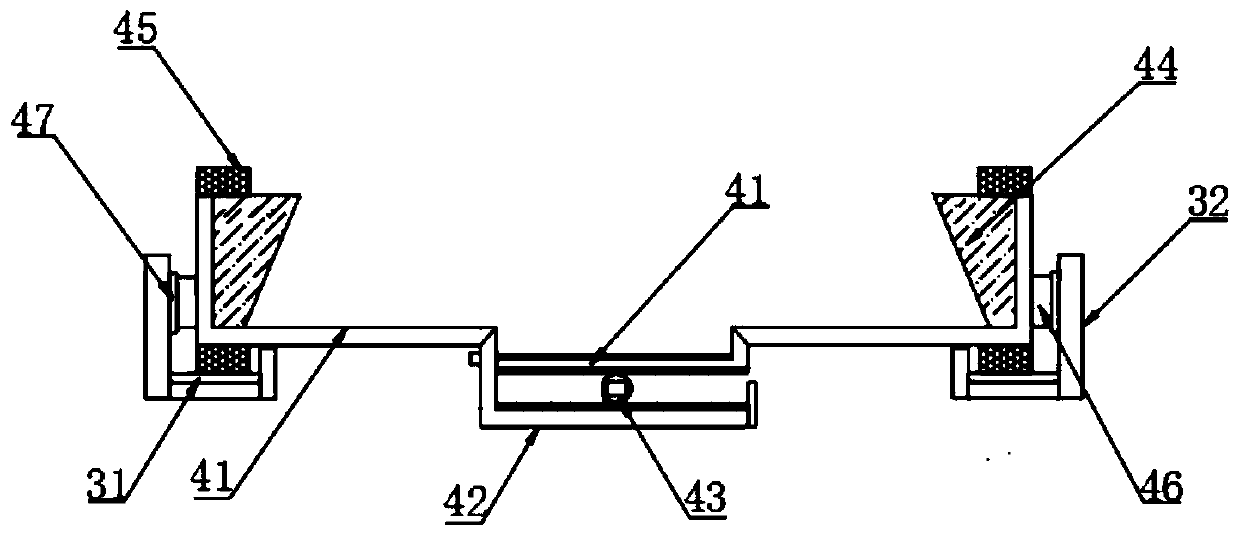

[0035] The carrying transmission mechanism 4 includes a carrying plate 41, a base plate 42, a drive gear 43, a limit seat 44, a sliding block 45, a motor 46 and a transmission seat 47, and the carrying plate 41 and the base plate 42 are integrated and the number is set to Two, two described bearing plates 41 are all provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com